Insert clamping device for vamp color spraying

A technology of color spraying and shoe uppers, applied in the direction of shoemaking machinery, applications, footwear, etc., to ensure personal safety and health, reduce production costs, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

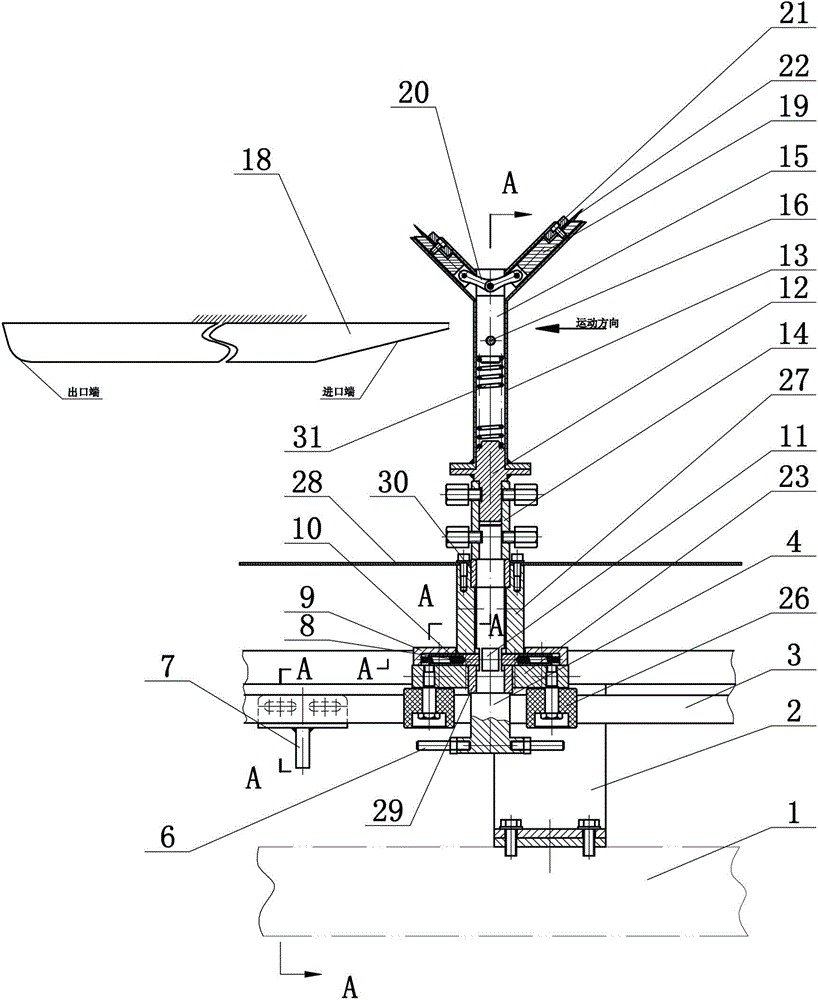

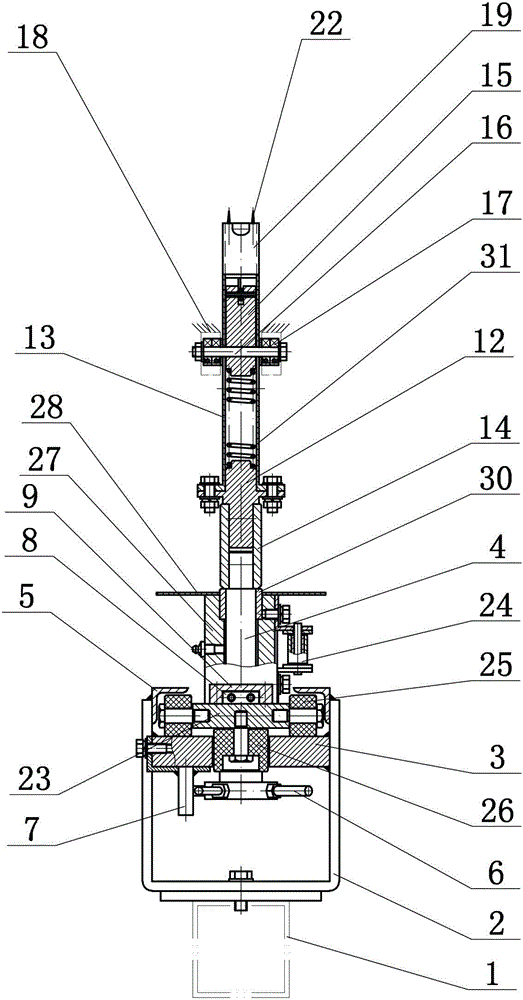

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] Such as figure 1 , figure 2 As shown, a kind of inserting and holding device for upper color spraying includes a frame 1, a lower rail bracket 2 is arranged on the frame 1, a lower rail 3 is fixed on the lower rail bracket 2, and a shoe fork shaft 4 is worn on the plug. In the frame bottom plate 23, a lower sliding copper sleeve 29 is arranged between the shoe fork shaft 4 and the frame bottom plate 23, and lower rollers 25 are arranged on both sides of the frame bottom plate 23, and the lower rollers 25 move along the lower guide rail 3, thereby driving the frame bottom plate 23 Moving along the lower guide rail 3, guide wheels 26 are arranged at the front and rear ends of the frame base plate 23, the guide wheels 26 are arranged in the guide groove in the middle of the lower guide rail 3, the middle part of the shoe fork shaft 4 is installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com