Thrust part used on inner ring measuring device of automatic ball bearing assembling machine

A technology of measuring devices, assembly machines, applied in the direction of bearing elements, shafts and bearings, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

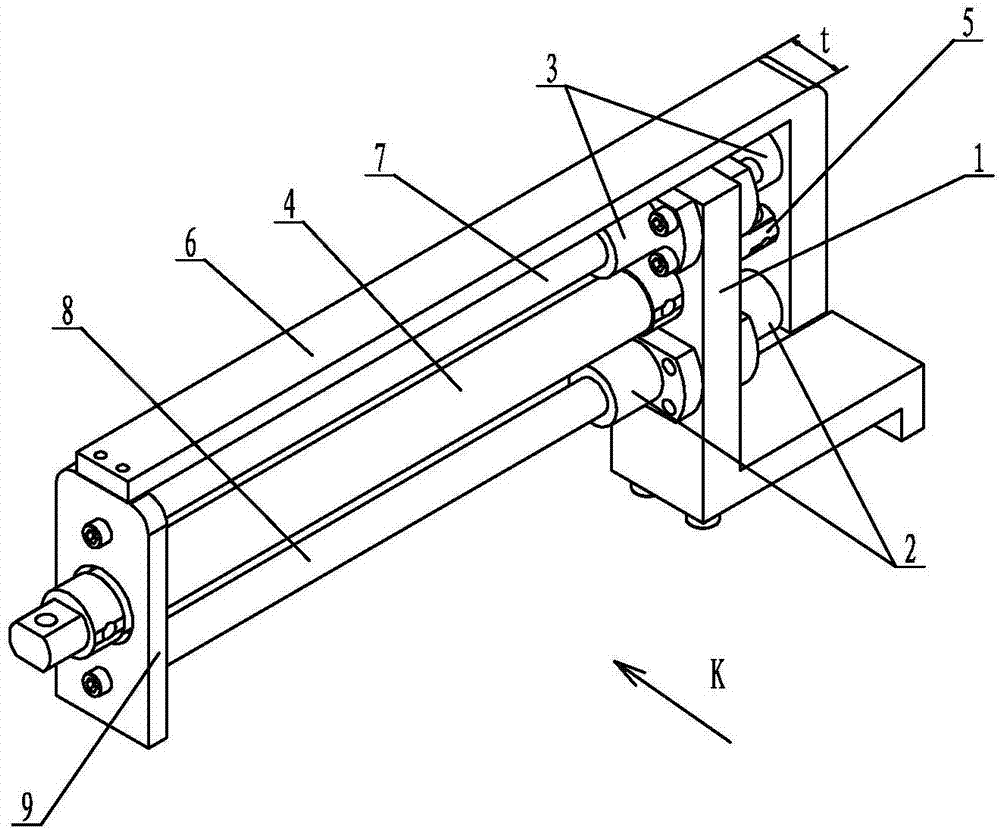

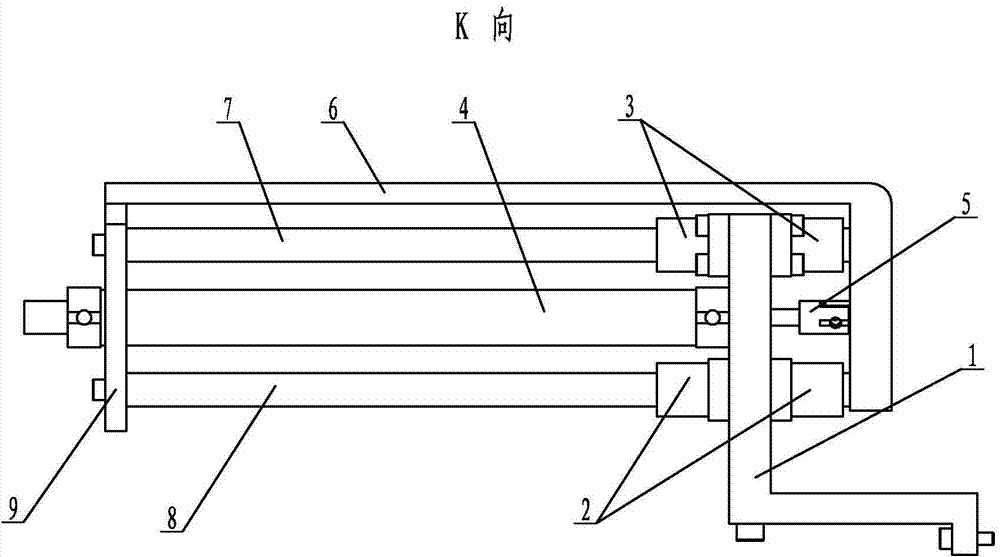

[0010] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment includes a thrust bracket 1, a thrust cylinder 4, a connector 5, a push body 6, an upper sliding column 7, a lower sliding column 8, a support plate 9, two lower sliding sleeves 2 and two upper sliding sleeves 3 , the two upper sliding sleeves 3 are arranged above the two lower sliding sleeves 2, the two upper sliding sleeves 3 are symmetrically fixed on both sides of the thrust bracket 1, and the two lower sliding sleeves 2 are symmetrically fixed on both sides of the thrust bracket 1, The rear end of the upper sliding column 7 passes through the upper sliding sleeve 3 and is fixedly connected with the pushing body 6, the rear end of the lower sliding column 8 passes through the sliding sleeve 2 and is fixedly connected with the pushing body 6, and the front ends of the upper sliding column 7 and the lower sliding column 8 Both are fixedly connected with the supp...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 The present embodiment will be described. The width t of the pusher 6 in the present embodiment is the same as the width of the bearing inner ring S to be measured. Other components and connections are the same as those in the first embodiment.

[0012] Working principle of the present invention:

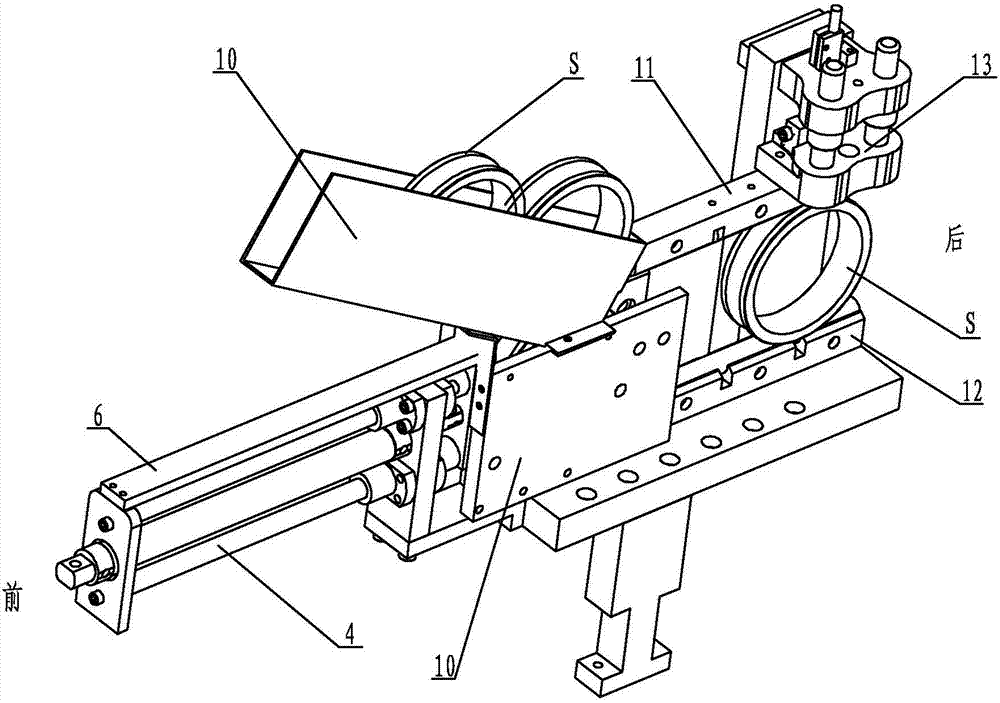

[0013] (1) Install the thrust parts on the front ends of the right splint 3 and the left splint 4, and the connector 5 faces the channel between the right splint 3 and the left splint 4.

[0014] (2) Initially, the piston of the thrust cylinder 4 is in a retracted state. When the inner ring S of the bearing to be measured needs to be sent to the detection position (that is, between the upper measuring body 11 and the lower measuring body 12), the piston of the thrust cylinder 4 is pushed out The connecting head 5 drives the pushing body 6 to move backward, and the pushing body 6 drives the upper sliding column 7, the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com