Suspension components on outer ring measuring devices for automatic ball bearing assembly machines

A technology for suspension components, measuring devices, used in bearing elements, mechanical bearing testing, shafts and bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

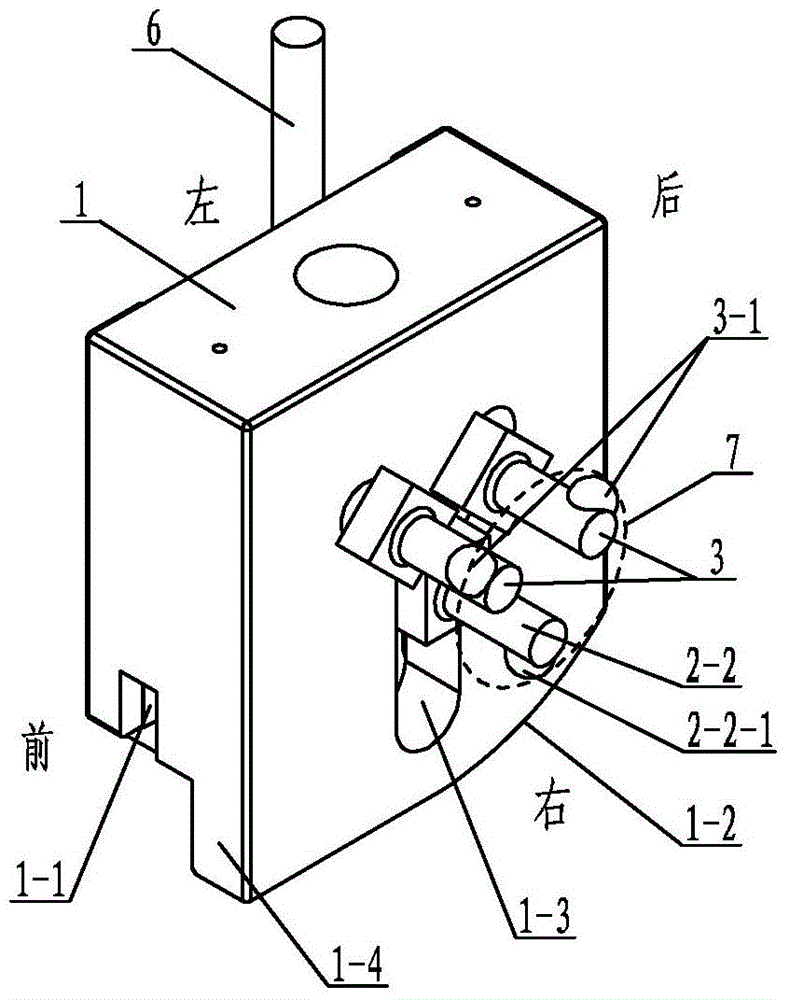

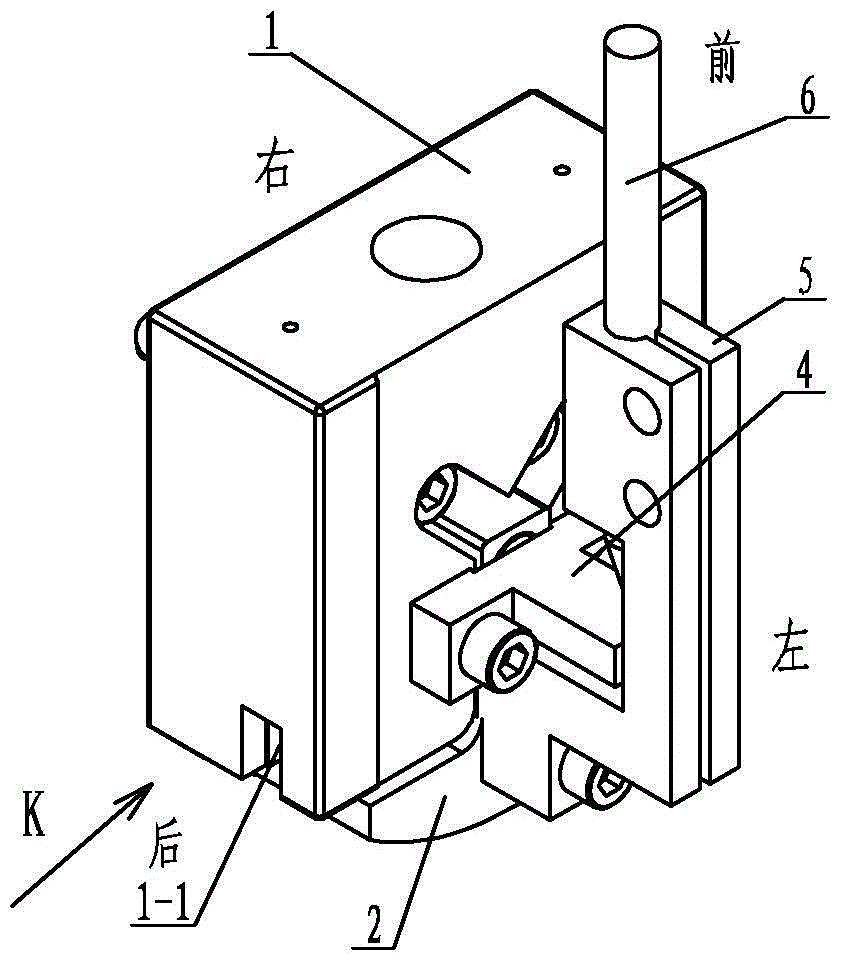

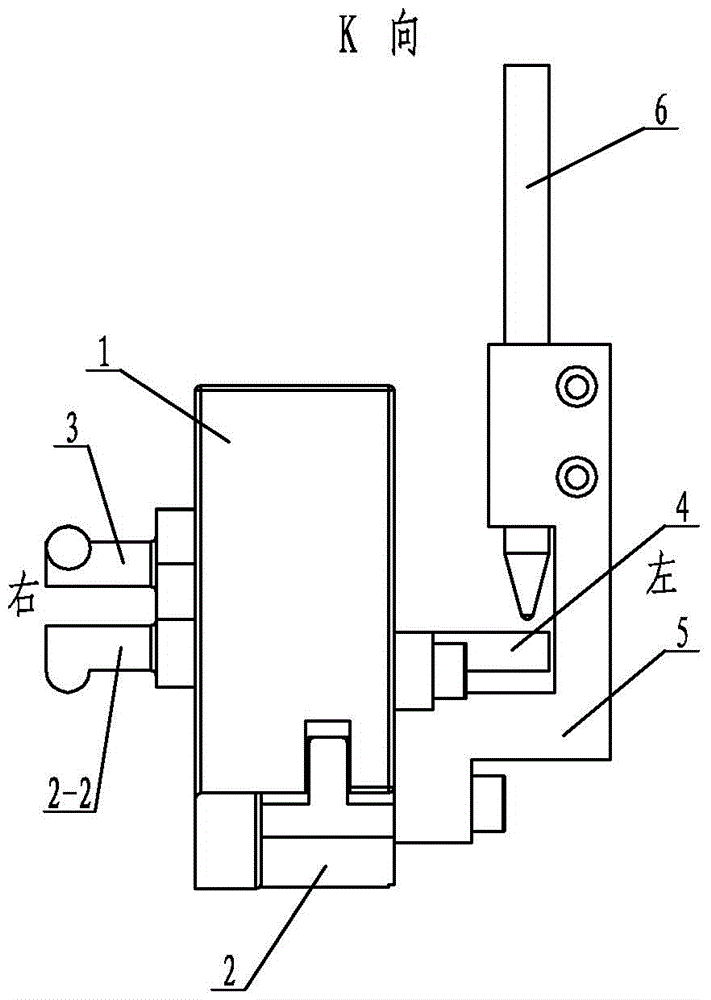

[0012] Embodiment 1: Combining Figure 1 to Figure 3 Illustrating this embodiment, this embodiment includes a main measuring body 1, a moving measuring body 2, a measuring fixed block 4, a measuring moving block 5, an outer ring measuring sensor 6 and two fixed support rods 3. The moving measuring body 2 is formed by the moving measuring body. The seat 2-1, the movable support rod 2-2, the two measuring columns 2-3 and the two compression springs 2-4 are composed. The middle part of the movable measuring body seat 2-1 is provided with a mounting seat 2-1-1. The upper end surface of 2-1-1 is provided with a long groove 2-1-2 for the movable measuring support rod, and the movable measuring body seat 2-1 is provided with mounting ribs 2-1 on both sides of the mounting seat 2-1-1. 1-3, a measuring column 2-3 is fixed on each mounting rib 2-1-3, a compression spring 2-4 is set on the upper end of each measuring column 2-3, and the movable support rod 2-2 is set on the movable measu...

specific Embodiment approach 2

[0013] Specific implementation mode 2: Combining figure 1 Describing this embodiment, the two inclined grooves on the Y-shaped through grooves 1-3 in this embodiment are symmetrically arranged relative to the vertical grooves. In this way, the fixed support rod 3 and the movable support rod 2-2 are evenly distributed along the circumference, and the contact between the two spherical fixed measuring fulcrums 3-1 and one dynamic measuring fulcrum 2-2-1 in the inner diameter of the outer ring T of the bearing under test is ensured. The points are evenly distributed, so that the measured value of the T dimension of the bearing outer ring is more accurate. Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation three: combination figure 1 Illustrating this embodiment, the included angle between the two inclined grooves on the Y-shaped through grooves 1-3 in this embodiment is less than or equal to 90°. In this way, the fixed support rod 3 and the movable support rod 2-2 are evenly distributed along the circumference, and the contact between the two spherical fixed measuring fulcrums 3-1 and one dynamic measuring fulcrum 2-2-1 in the inner diameter of the outer ring T of the bearing under test is ensured. The points are evenly distributed, so that the measured value of the T dimension of the bearing outer ring is more accurate. Other compositions and connection relationships are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com