Resistance strain gauge adapter device and test method for testing rail residual stress

A resistance strain gage and residual stress technology, applied in measuring devices, measuring forces, instruments, etc., can solve the problems of sample waste, affecting the accuracy and validity of test results, short circuit of resistance strain gages, etc., and achieve accurate residual stress values. and effective, the test data is accurate and effective, and the residual stress value is accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the drawings and embodiments.

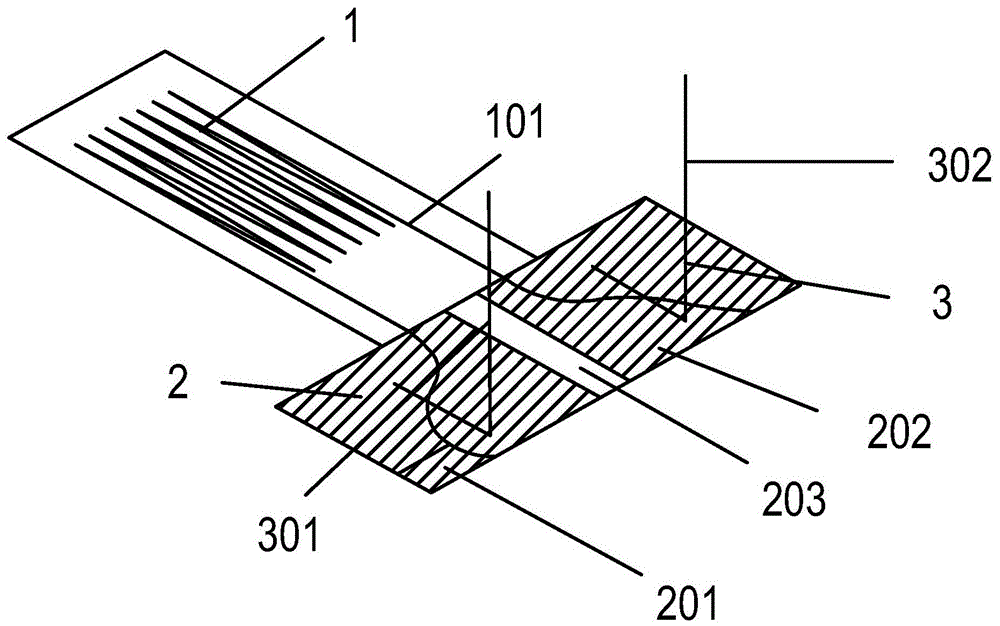

[0038] Such as figure 1 As shown, the resistance strain gauge adapter device for testing the residual stress of a steel rail of the present invention includes an adapter plate 2, an adapter post 3, and the adapter post 3 is a copper wire section with a diameter of 0.3 to 0.8 mm and a length of 8 to 15 mm; The connecting plate 2 is a conductive substrate with an insulating area 203 in the middle. The insulating area 203 insulates the conductive substrate into a first conductive area 201 and a second conductive area 202. The adapter plate 2 has a length of 7-15 mm and a width of 4 ~8mm; the transfer post 3 includes a first transfer post 301 and a second transfer post 302 soldered on the first conductive area 201 and the second conductive area 202 correspondingly.

[0039] Among them, the adapter post 3 is used to electrically connect to the strain tester wire, and the adap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com