Rotary feed distributor

A dispenser and feed technology, which is applied in animal feeding devices, applications, poultry industry, etc., can solve the problems of cross pollution and small outlet splicing angle, so as to increase the splicing angle and reduce the cross pollution of serial warehouses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with specific examples.

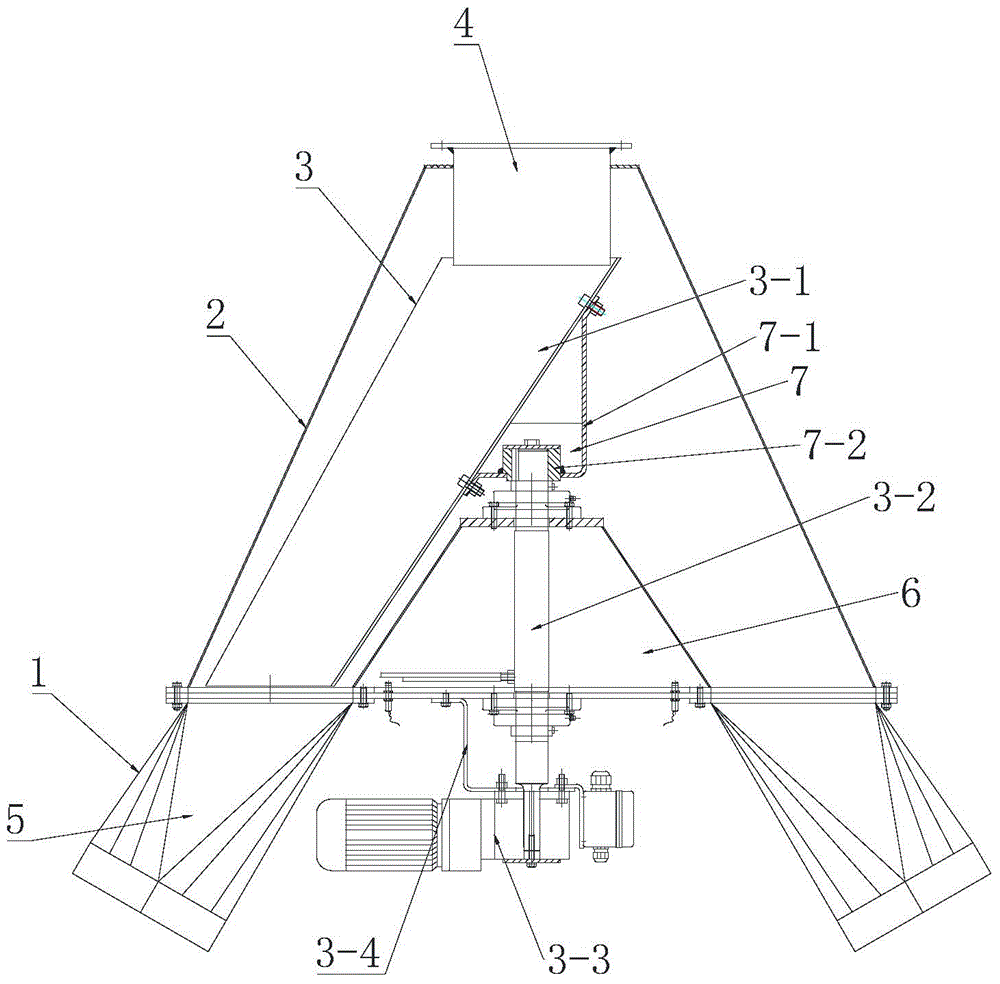

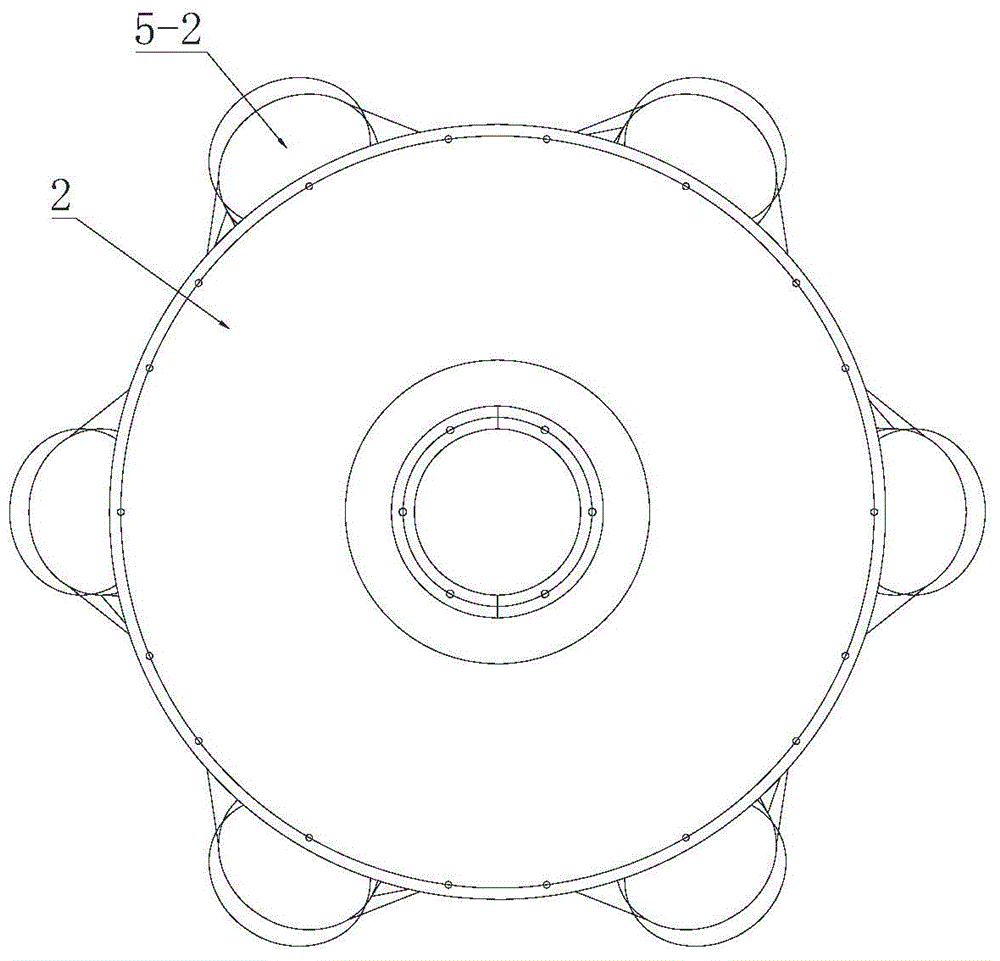

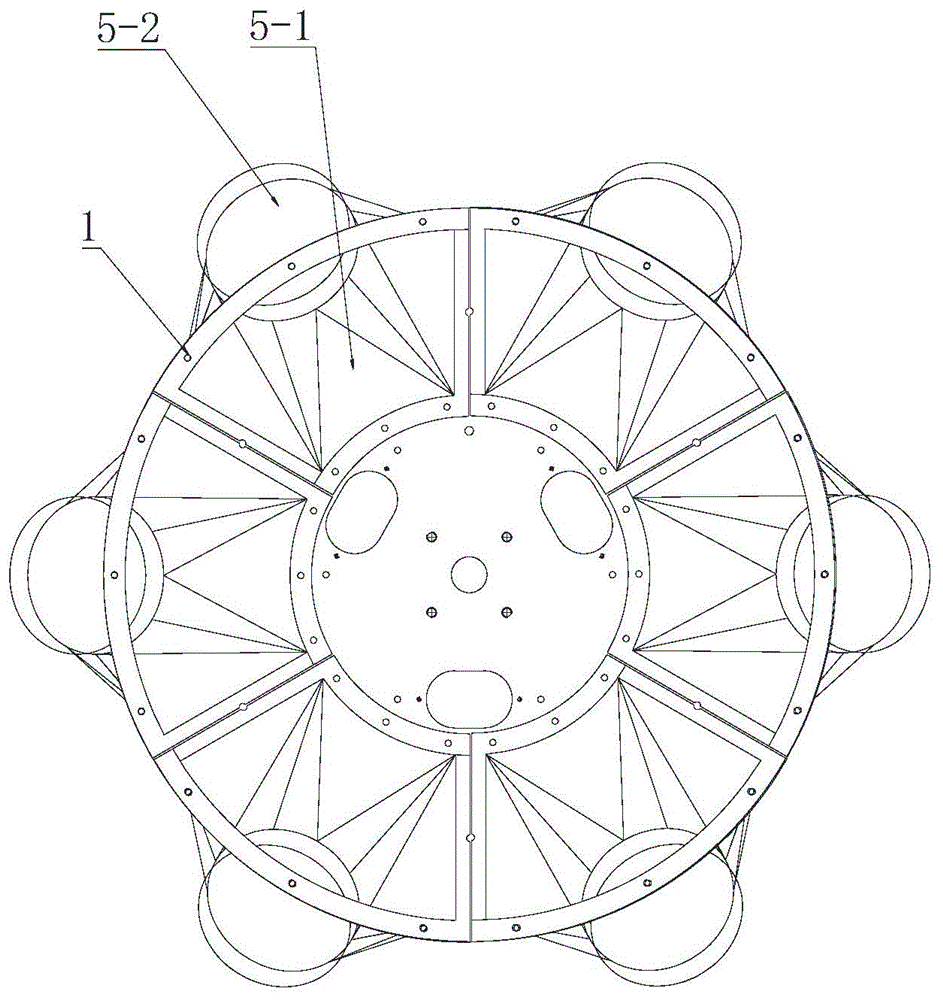

[0016] Such as Figure 1-Figure 3 As shown, the present invention is a rotary feed distributor, which includes a distribution tray 1, a distribution case 2 fixed above the distribution tray 1, and a distribution mechanism 3 arranged in the distribution case 2, the distribution cover The top of the shell 2 is provided with a feed inlet 4, and the distribution tray 1 is provided with a plurality of discharge bins 5 along its circumference, and the plurality of discharge bins 5 are sequentially connected along the circumference to form a ring-shaped material receiving structure, and the distribution mechanism 3 It includes a material guiding groove 3-1, a rotating shaft 3-2 connected with the material guiding groove, and a motor device 3-3 for driving the rotating shaft to rotate.

[0017] The top of the material guide chute 3-1 is arranged below the feed port 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com