A low-torque self-sealing fire hydrant

A low-torque, fire hydrant technology, applied in fire rescue and other fields, can solve problems such as easy vibration, large pressure changes of seals, fire hydrant damage, etc., and achieve the effect of reducing the overall vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

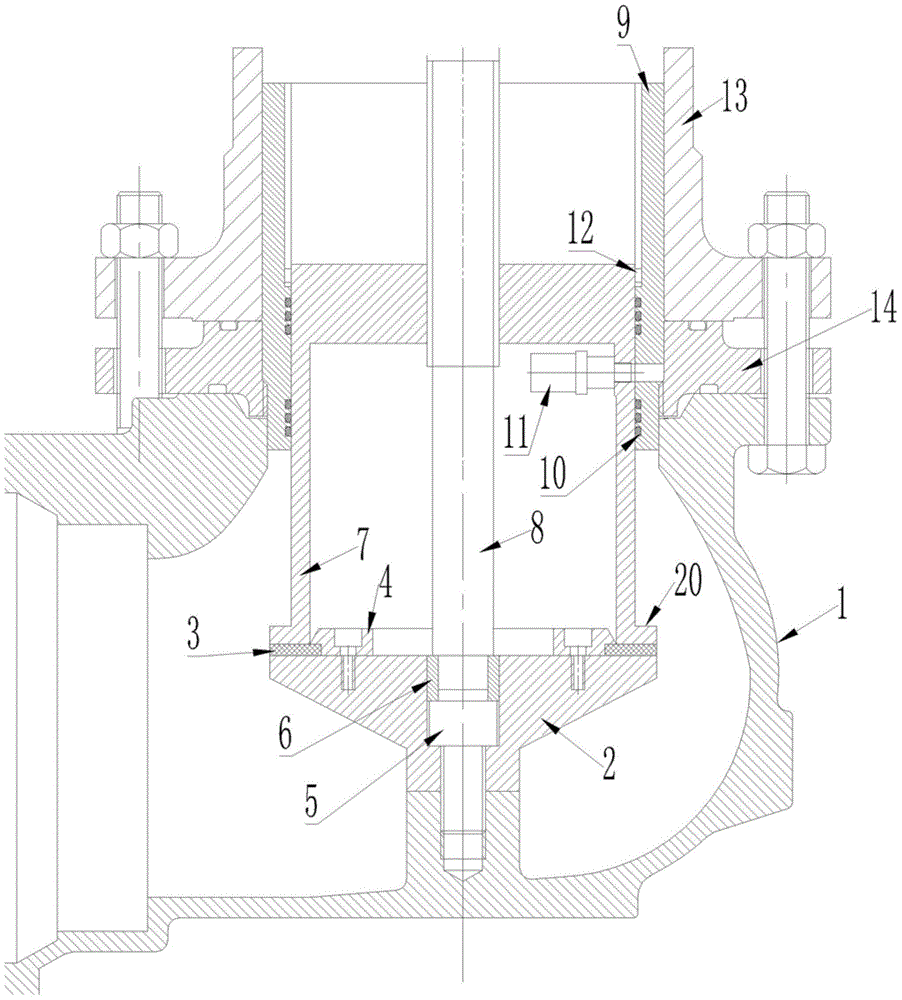

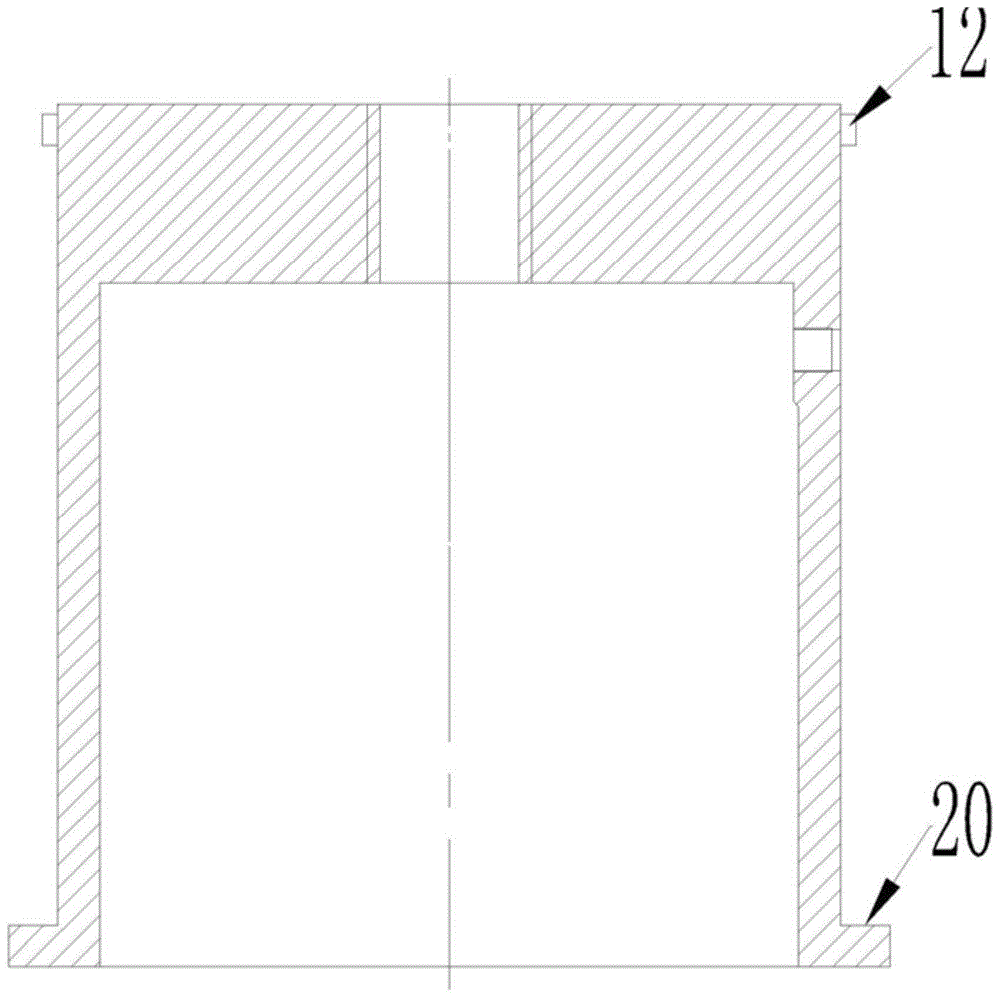

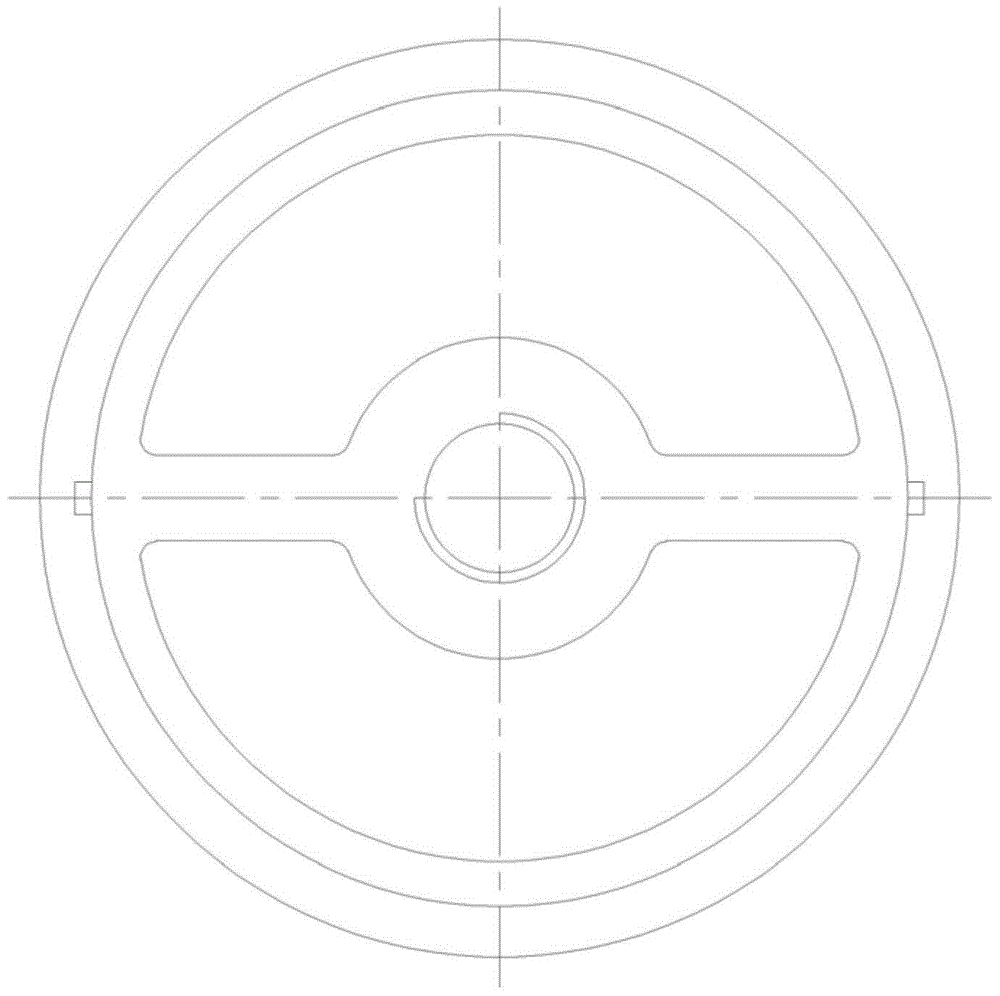

[0020] see Figure 1-4 , a low-torque self-sealing fire hydrant, comprising a plug body, the plug body is provided with a water inlet 1, and a tray 2 is fixedly arranged near the water inlet 1, and a valve shaft 8 is inserted on the tray 2, The valve shaft 8 is connected to the valve seat 7 through threads, the outer side of the valve seat 7 is sleeved in the guide cylinder 9, and the inner wall of the valve seat 7 is equipped with a valve so that the fluid flows from the valve seat 7 to the outside of the valve seat 7. The one-way valve 11, the wall of the guide cylinder 9 is provided with a through hole communicating with the outside, by turning the valve shaft 8 to make the valve seat 7 away from or close to the tray 2 to open or close the water inlet 1, when the When the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com