Method for Measuring Filtration Coefficient of Supercritical Carbon Dioxide Fracturing Fluid

A carbon dioxide, supercritical technology that can be used in measurement devices, surface/boundary effects, suspension and porous material analysis, etc., to solve problems such as narrowing of cracks, sand plugging, and unsatisfactory stimulation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

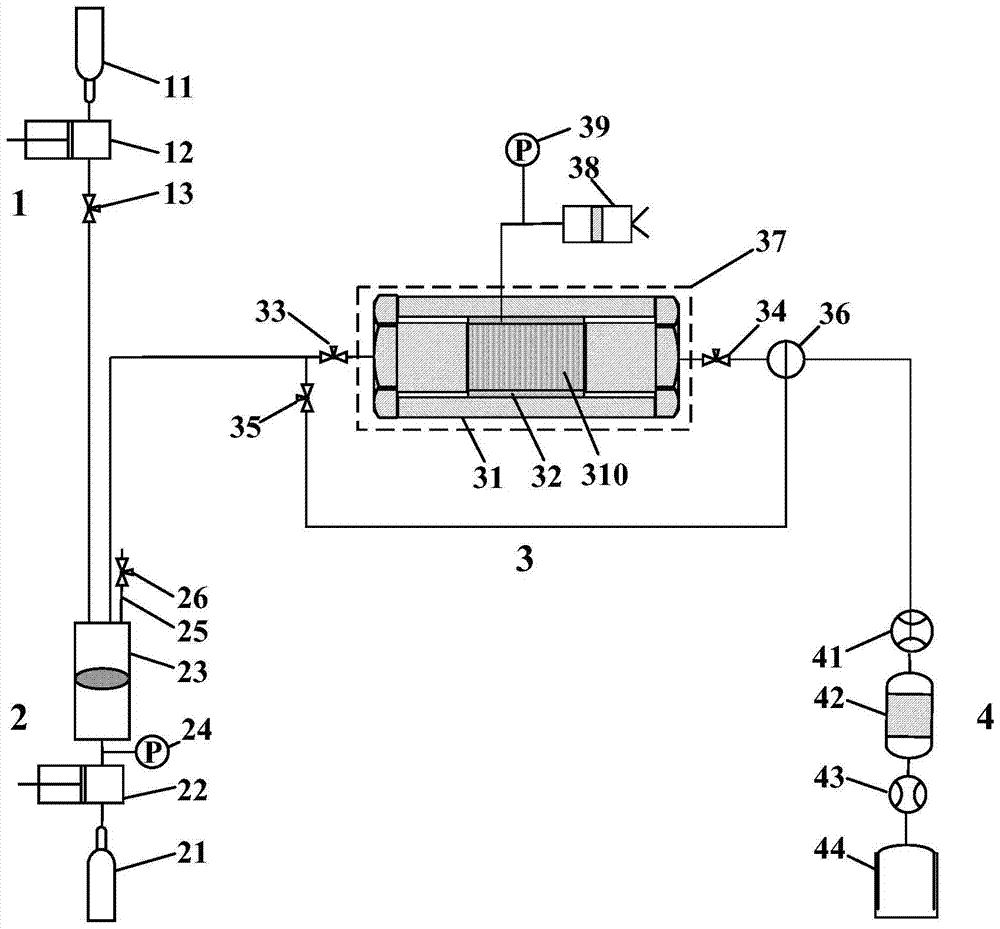

[0023] Such as figure 1 As shown, the device for measuring the fluid loss coefficient of supercritical carbon dioxide fracturing fluid includes: gas injection system 1, pressure control system 2, experimental model system 3 and measurement system 4; gas injection system 1 injects methane or carbon dioxide into the experimental model system 3 , the pressure control system 2 provides pressure for the experimental model system 3 and the gas injection system 1, the experimental model system 3 provides a high temperature and high pressure formation environment for the experiment, and the measurement system 4 measures the volume of different gases flowing out during the experiment.

[0024] The gas injection system 1 includes: a gas storage tank 11, a gas booster pump 12, a gas output screw valve 13, the gas storage tank 11, a gas booster pump 12, and a gas output screw valve 13 are connected in sequence through pipelines, and the gas storage tank 11 is a standard stainless steel ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com