Light guide plate and display module

A display module and light guide plate technology, which is applied in the field of backlight display, can solve problems such as difficult breakthroughs and insignificant light guide uniformity, and achieve the effect of improving backlight uniformity and backlight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

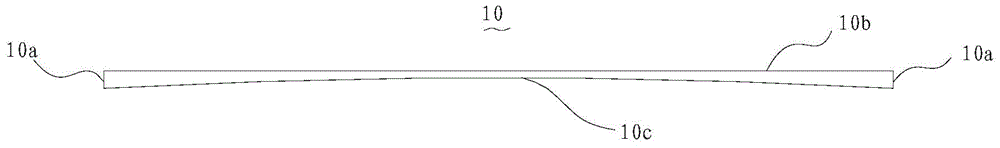

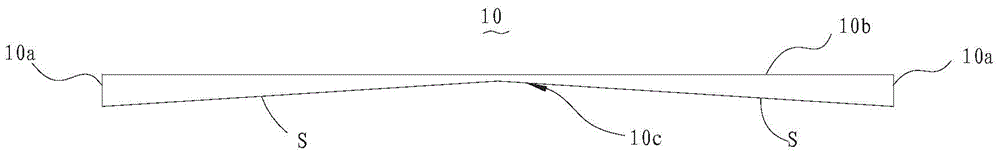

[0024] refer to Figure 1~2 The light guide plate 10 of this embodiment includes light incident surfaces 10a on both sides, a light exit surface 10b on the upper surface, and a scattering surface 10c with scattering dots on the lower surface, and the scattering surface 10c is recessed toward the direction of the light exit surface 10b.

[0025] Since the scattering surface 10c is recessed toward the light-emitting surface 10b, the light entering the light-incident surface 10a on both sides can enter the scattering surface 10c through a very short optical path, and then diverge toward the surroundings through the scattering surface 10c, and finally exit the light-emitting surface 10b has more even light.

[0026] Specifically, the scattering surface 10c is an arc surface (such as figure 1 shown). Alternatively, the scattering surface 10c is composed of a slope S inclined from the lower ends of the light incident surface 10a on both sides toward the light exit surface 10b (suc...

Embodiment 2

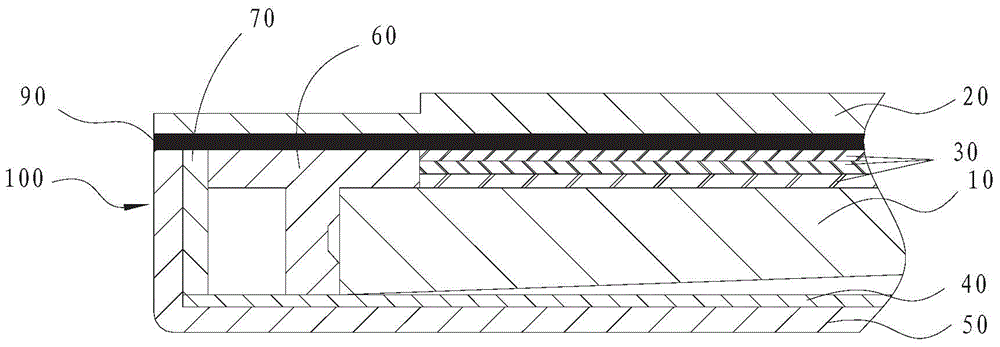

[0030] Such as Figure 4 As shown, the difference from Embodiment 1 is that the scattering surface 10c of this embodiment is coated with a reflective material, and the reflective material layer 10s is the reflective layer 40 of the backlight unit 100 to reflect the light emitted from the LED components 60 on both sides. The light entering the scattering surface 10c.

Embodiment 3

[0032] Such as Figure 5 As shown, the difference from Embodiment 1 is that the reflective layer 40 of this embodiment is a layer of reflective sheet provided separately, and the reflective sheet is closely attached to the scattering surface 10c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com