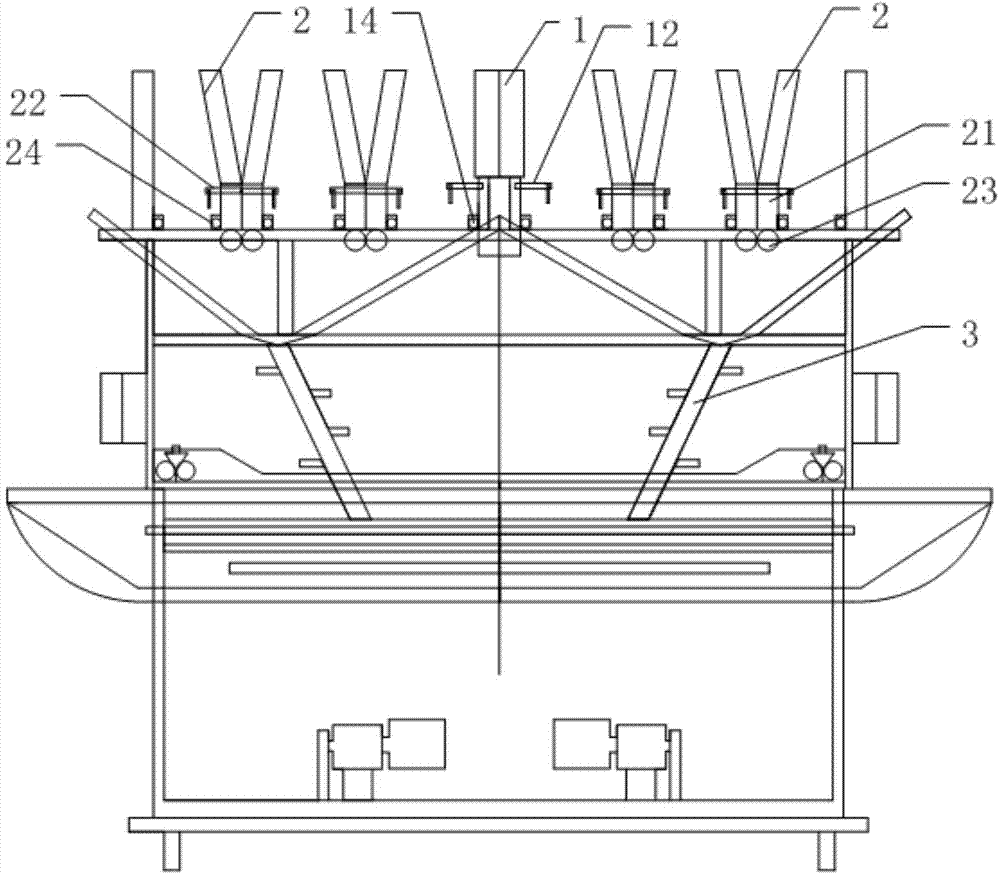

Multi-workstation-conveying tile printing device

A multi-station, cloth device technology, applied in printing devices, printing, typewriters, etc., can solve the problems of difficult preparation of manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

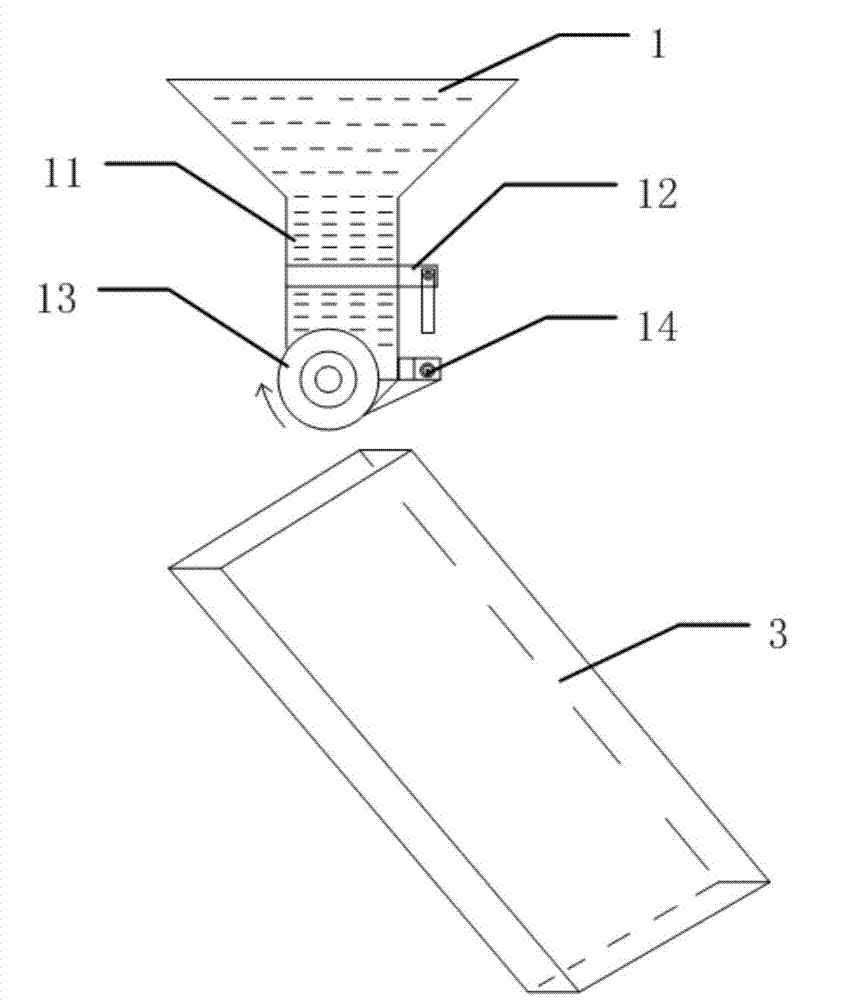

[0050] The main material valve 12 and the toner valve 22 are electronically controlled to open or close;

[0051] The control mechanism includes: a time setting module and a timing module; the time setting module is used to respectively set the opening or closing time of the main material valve 12 and each of the toner valves 22, and set the The order of opening or closing between the main material valve 12 and each of the toner valves 22;

[0052] The timing module is used to control the main material valve 12 and each of the toner valves 22 according to the opening or closing time of the main material valve 12 and each of the toner valves 22 set by the time setting module. The opening or closing time of the powder valve 22, and according to the opening or closing sequence of the main material valve 12 and each of the toner valves 22, control the main material valve 12 and each of the toner valves The opening or closing sequence between 22;

[0053] Specifically, the timing...

Embodiment approach 2

[0065] The control mechanism includes: a measurement setting module and a measurement module;

[0066] The metering setting module is used to set the opening or closing of the main material valve and each of the toner valves according to the usage of the main material and toner, and to set the main material valve and each of the toner valves. The sequence of opening or closing of the toner valves;

[0067] The metering module is used to measure the weight of the main material in the main material bin, and set the weight of the main material according to the metering setting module, control the opening or closing of the main material valve, and measure each toner The weight of the toner material in the silo, and set the weight of the toner material according to the metering setting module, control the opening or closing of each of the toner valves, and set the main material valve and each of the toner The opening or closing sequence between the toner valves is controlled, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com