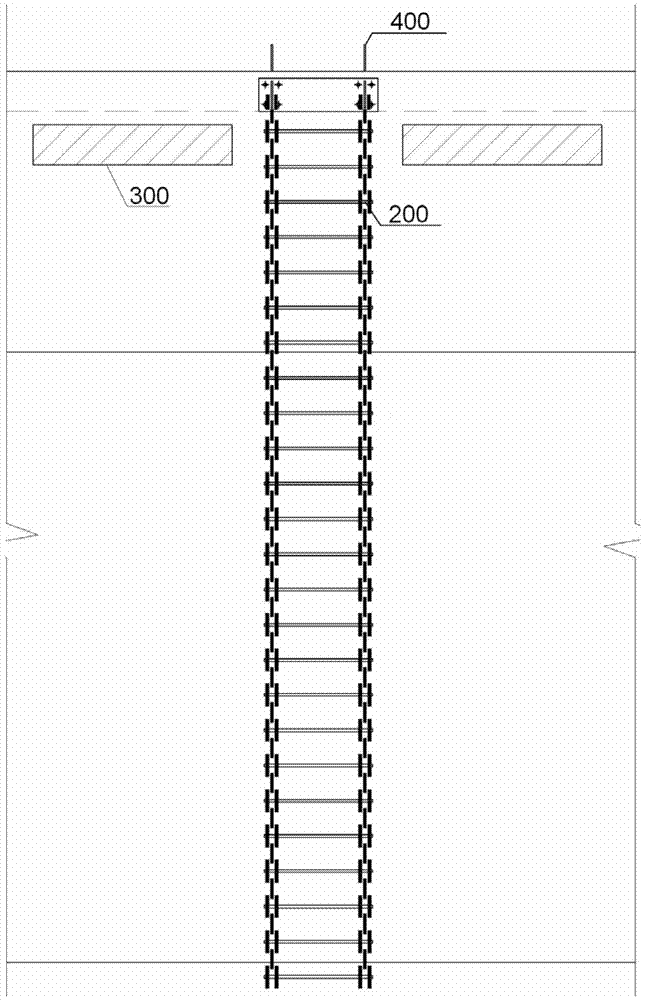

Novel fender, anti-collision crawling ladder and dock with novel fenders and anti-collision crawling ladders

A fender and wharf technology, applied to ladders, shipping equipment, buildings, etc., can solve problems such as ladder impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

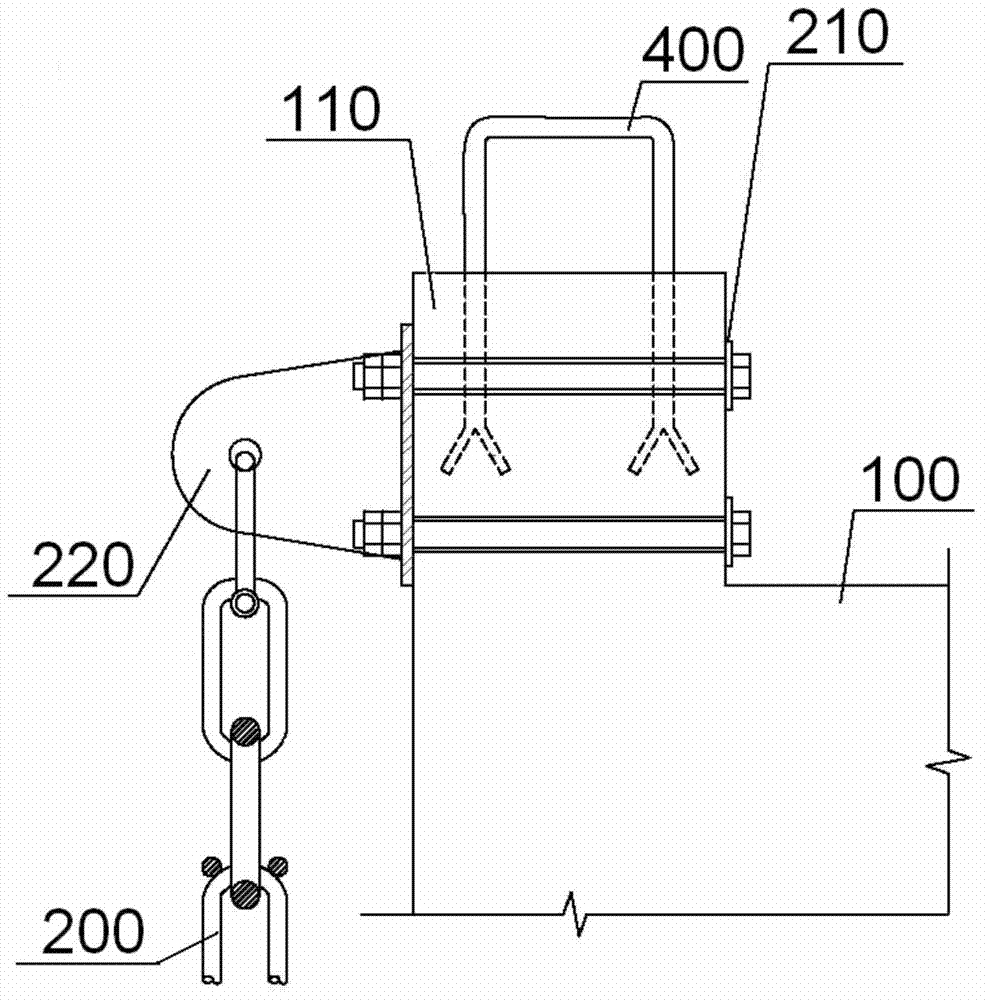

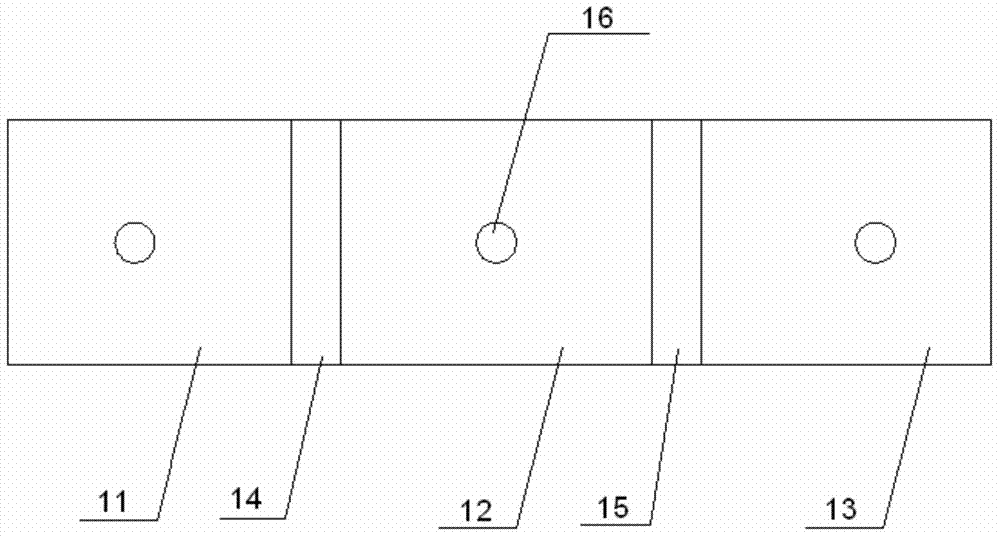

[0041] Referring to Fig. 2, in an embodiment of the present invention, the new fender is composed of three connected columns.

[0042] Such as Figure 2A As shown, among the three cylinders, the first cylinder 11 and the third cylinder 13 are located at the two ends of the middle cylinder 12, and there are gaps between adjacent cylinders, that is, the first gap 14 and the second gap 15 .

[0043] Such as Figure 2B As shown, the side of each cylinder has a plane 18, and the other sides form a smooth arc surface, such as Figure 2B As shown, the cross-section of the cylinder may be made into a D-shape or similar. The planes of the first cylinder 11 , the middle cylinder 12 and the third cylinder 13 are sequentially connected to form a rectangular plane.

[0044] In the cylinder of the fender 1, there are also passages 19 running through both ends of the cylinder. The channel 19 can reduce the weight of the fender and at the same time play a certain buffering effect.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com