Mortise and tenon spring lock cylinder

A mortise-and-mortise type, lock cylinder technology, used in cylinder marble locks, construction locks, locks with turning keys, etc. "Bump key" to unlock); non-this lock key can be entered, etc., to achieve the effect of high safety factor and reduce the probability of hitting the key to unlock the lock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

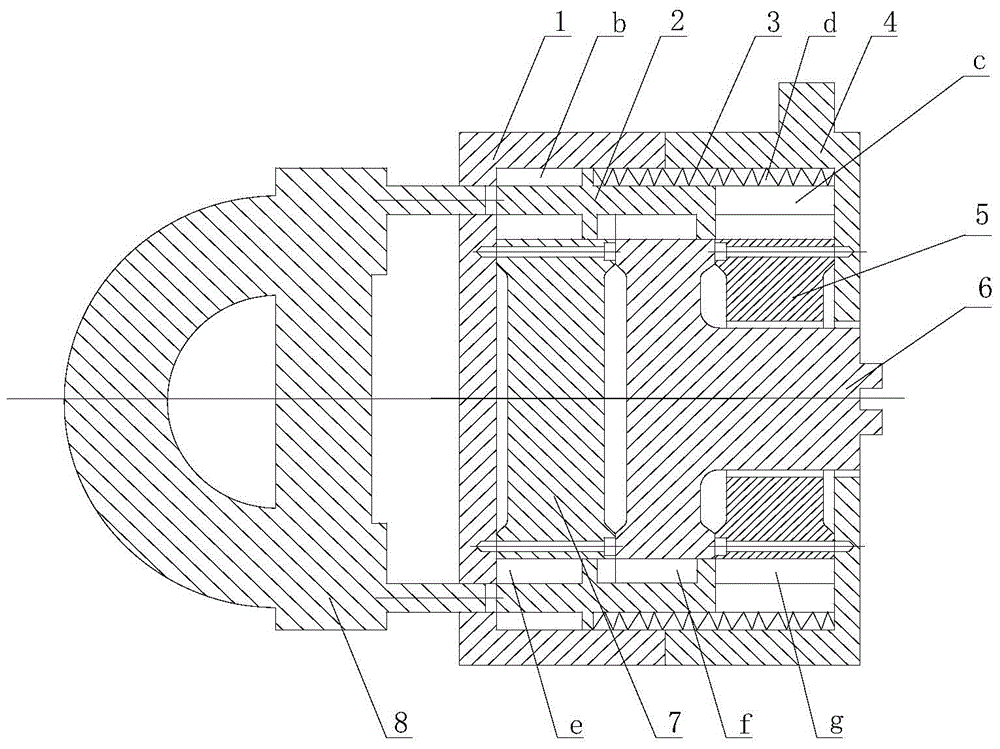

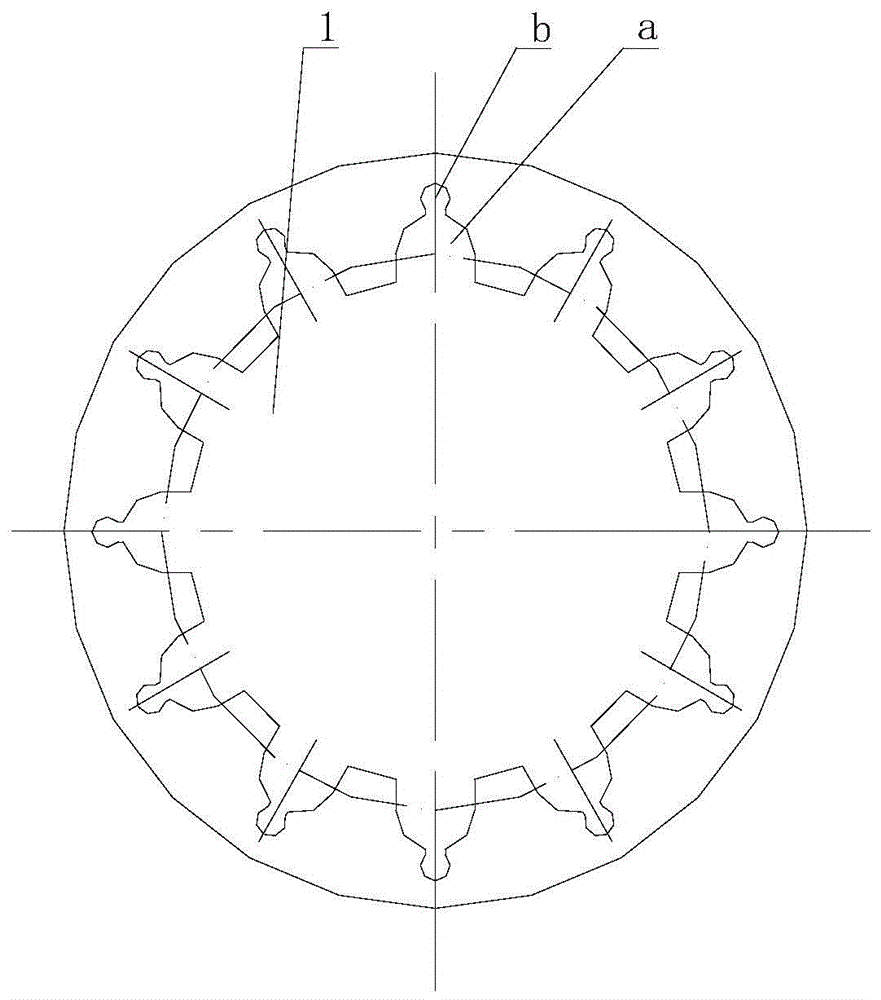

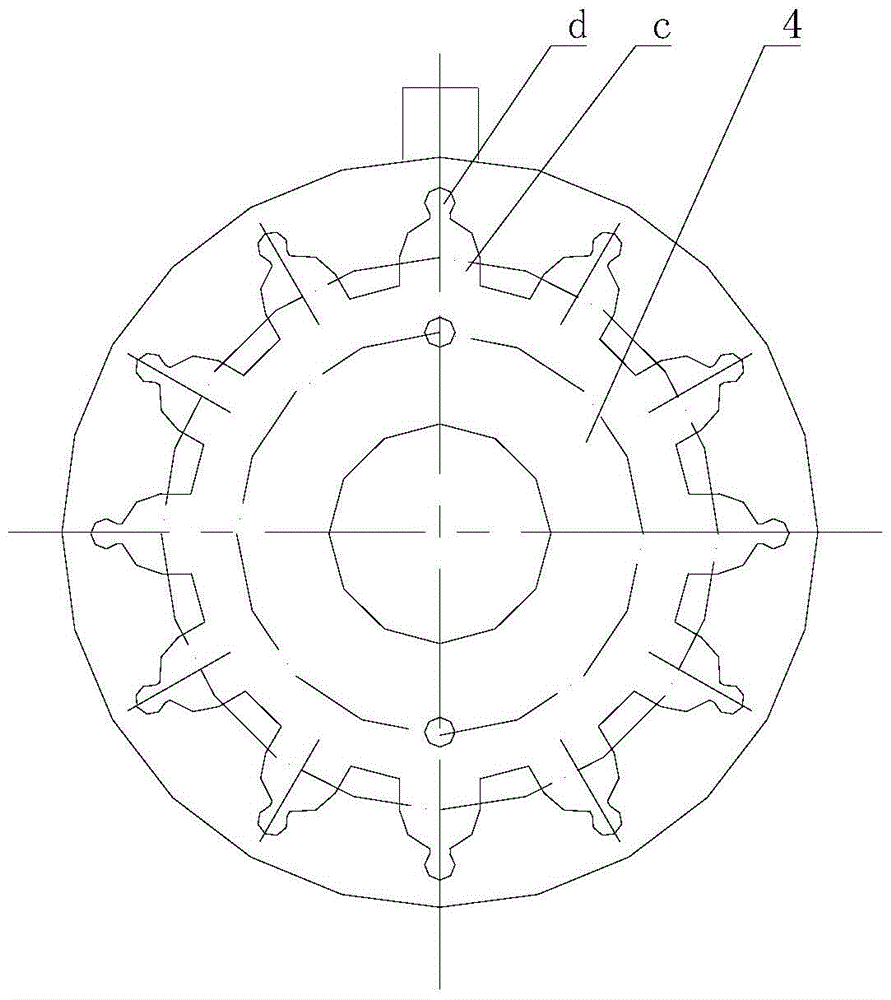

[0014] exist figure 1 , 2 , 3, and 4, the mortise and tenon type rebound sub-lock cylinder of the present invention consists of a front lock cylinder cover 1, a marble 2, a spring 3, a rear lock cylinder cover 4, a rear inner lock cylinder pad 5, an inner lock cylinder body 6, a front inner The lock core pad 7 and the key 8 are connected to form. The inner side wall of the front lock cylinder cover 1 is processed with 12 first grooves a that equally divide the circumference. It is a circular second groove b, and the bottom of the front lock cylinder cover 1 is processed with 12 circular through holes that equally divide the circumference as keyholes, and the keyholes are used to insert the key 8. There are 12 cylinders corresponding to the keyhole processed in the direction, and the pin 2 is installed in the first groove a. The geometric shape of the pin 2 is F-shaped. The table is stuck in the second slot b, and the center position of the inner bottom of the front lock cyl...

Embodiment 2

[0017] In this embodiment, the inner side wall of the front lock cylinder cover 1 is processed with 10 first grooves a that equally divide the circumference. The bottom of a is processed with a groove b with a circular cross section, and the bottom of the front lock cylinder cover 1 is processed with 10 circular through holes that equally divide the circumference as keyholes. A key 8 is arranged in the keyhole, and the structure of the key 8 is a circle. 10 cylinders corresponding to the key holes are processed on the disk along the circumferential direction, and the center position of the inner bottom of the front lock cylinder cover 1 is fixed with a threaded fastening connector to install the front inner lock cylinder pad 7, and the front inner lock cylinder pad 7 The geometric shape is cylindrical, and the cylindrical outer surface is processed with 10 fifth through grooves e that equally divide the circumference. The vertical section of the fifth through groove e is rectan...

Embodiment 3

[0019] In this embodiment, the inner side wall of the front lock cylinder cover 1 is processed with two first grooves a that equally divide the circumference. The bottom of a is processed with a groove b with a circular cross section, and the bottom of the front lock cylinder cover 1 is processed with two circular through holes corresponding to the first groove a as key holes, and a key 8 is arranged in the key hole. The structure of 8 is that two cylinders corresponding to the key holes are processed on the disc along the circumferential direction, and the center position of the inner bottom of the front lock cylinder cover 1 is fixedly installed with a front inner lock cylinder pad 7 with a threaded fastening connector. The geometric shape of the lock cylinder pad 7 is cylindrical, and the cylindrical outer surface is processed with 2 fifth through grooves e that equally divide the circumference. The vertical section of the fifth through groove e is rectangular, and the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com