On-site visitiation tooling

A tooling and on-site technology, which is applied in the field of measuring electric variable devices, can solve the problems that the sliding distance of the watch support cannot be accurately controlled and the connection structure is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

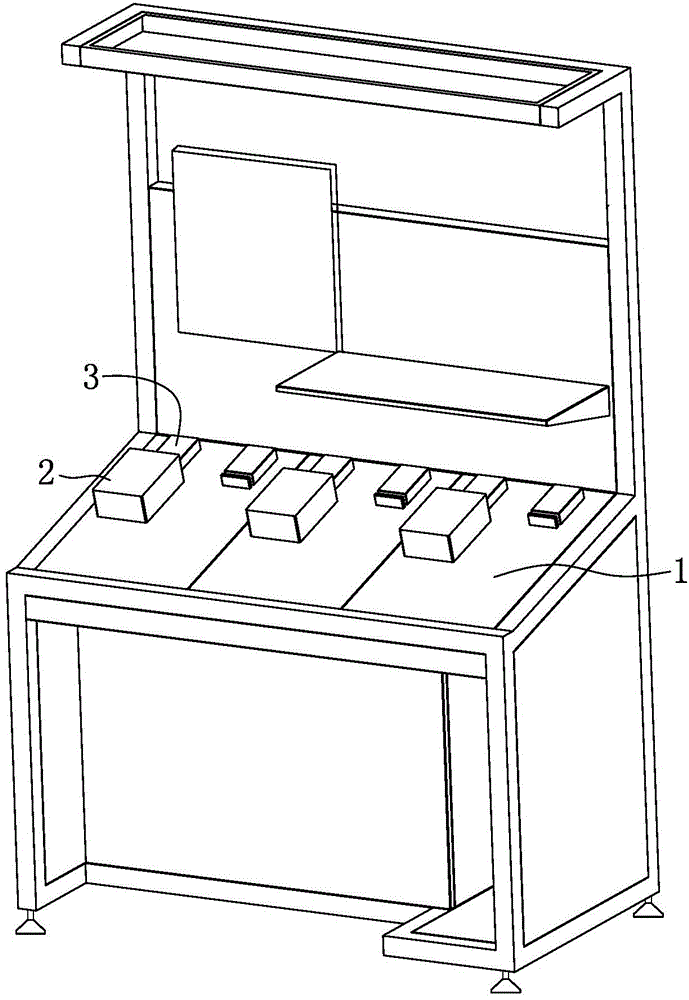

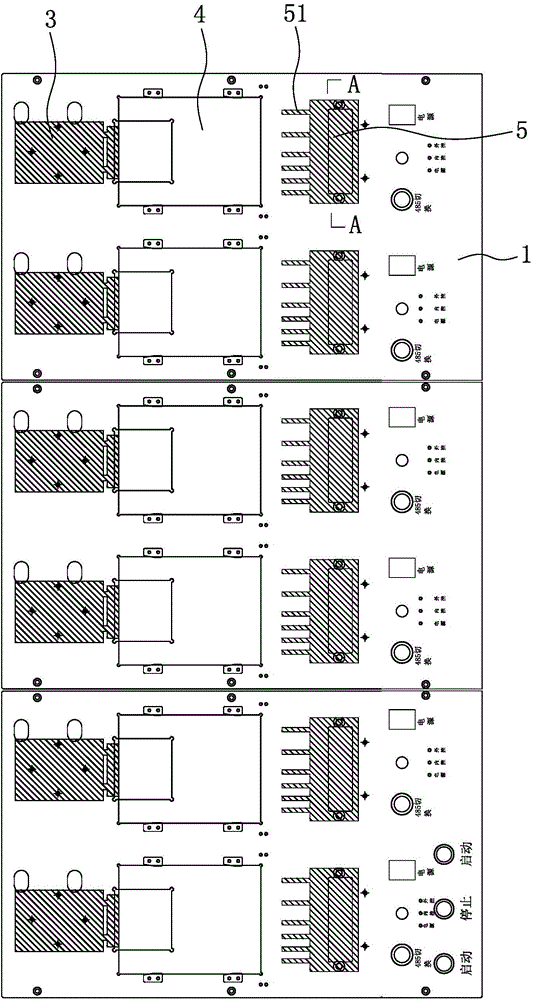

[0021] refer to figure 1 and figure 2 , tooling for on-site inspection, including a tooling panel 1 set at an inclination, a meter holder 5 is arranged on the tooling panel 1, and a pin 51 parallel to the tooling panel 1 is arranged on the upper end of the meter holder 5, and the meter holder 5 and the electric energy meter 2 conflict with each other , and, the pin 51 is inserted into the electric energy meter 2 to prevent the electric energy meter 2 from sliding along the tooling panel 1 .

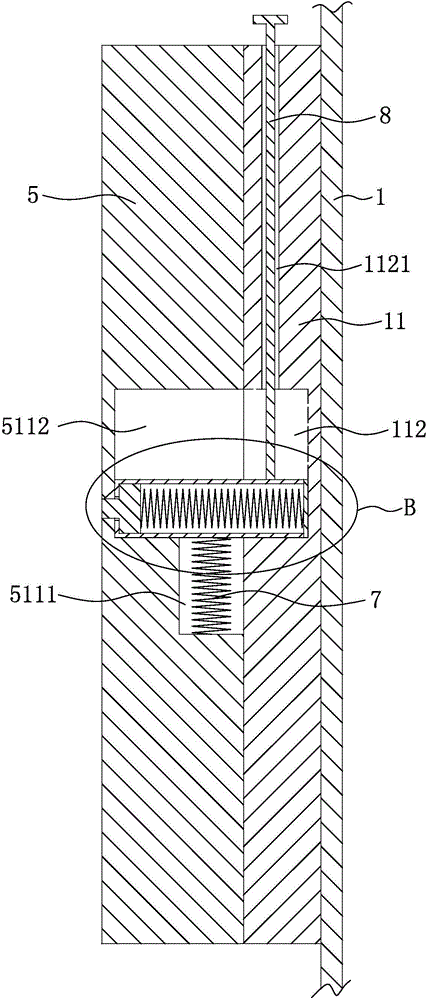

[0022] refer to image 3 , Figure 4 and Figure 5 The tooling panel 1 is provided with a guide groove 111 and a locking groove 112 communicating with the guide groove 111 on the end face of the tooling panel 1 facing the table holder 5. The guide groove 111 is vertically arranged to limit the sliding distance of the table holder 5 relative to the tooling panel 1, and the lock Tight grooves 112 are arranged laterally to prevent the watch holder 5 from sliding relative to the tooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com