Clamping and locating mechanism and clamping and locating method

A clamping positioning and splinting technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of insufficient operating space and inability to meet requirements, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

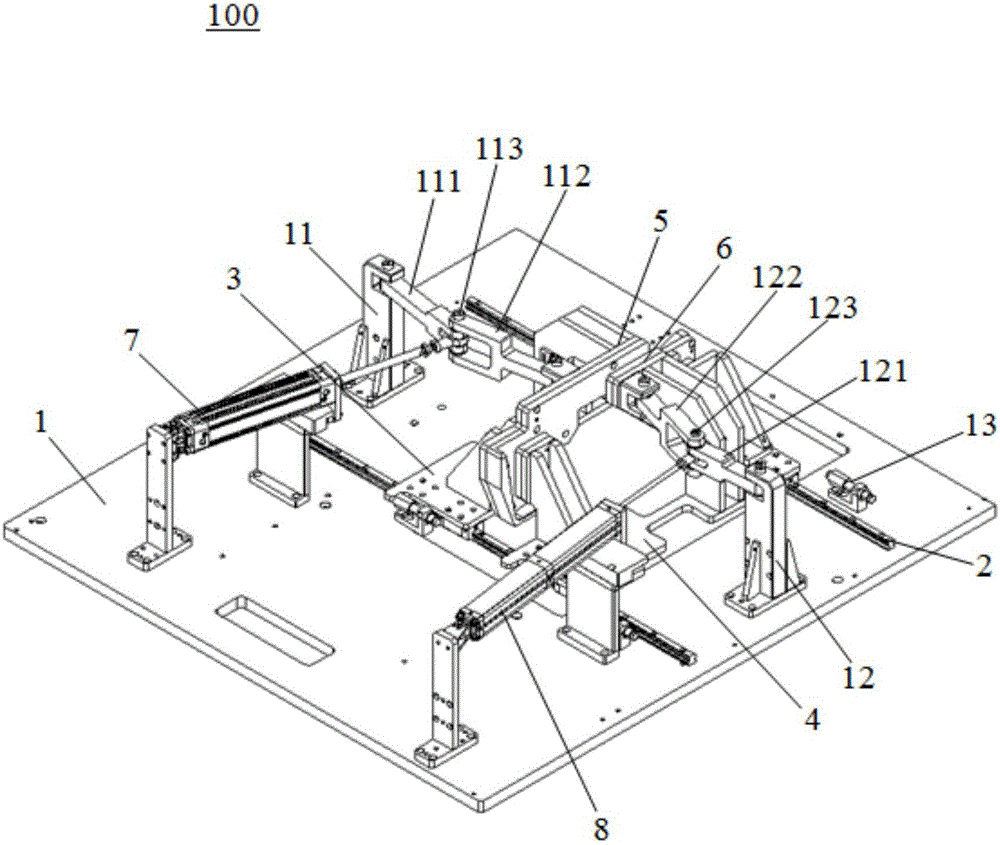

[0022] Please refer to figure 1 , the present embodiment is a clamping and positioning mechanism 100, which includes a support plate 1, a slide rail 2 fixed on the support plate 1, a first connecting plate 3 and a second connecting plate 4 that are movably arranged on the slide rail 2, fixed on the second connecting plate The first clamping plate 5 on a connecting plate 3, the second clamping plate 6 fixed on the second connecting plate 4, the first air cylinder 7 that drives the first connecting plate 3 to slide on the slide rail 2 and drives the second connecting plate 4 in The second cylinder 8 that slides on the slide rail 2. The first cylinder 7 and the second cylinder 8 are located at a certain distance outside the slide rail 2 .

[0023] A first support 11 and a second support 12 are provided on both ends of the slide rail 2 on the support plate 1 . The clamping positioning mechanism 100 also includes a first link 111 movably arranged on the first support 11, a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com