An engine blade positioning and clamping device

An engine blade, positioning and clamping technology, applied to the surface coating liquid device, coating, etc., can solve the problems that the quality cannot be effectively guaranteed, and the glue coating process is difficult to control, so as to improve the production and processing efficiency and facilitate Easy to operate and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

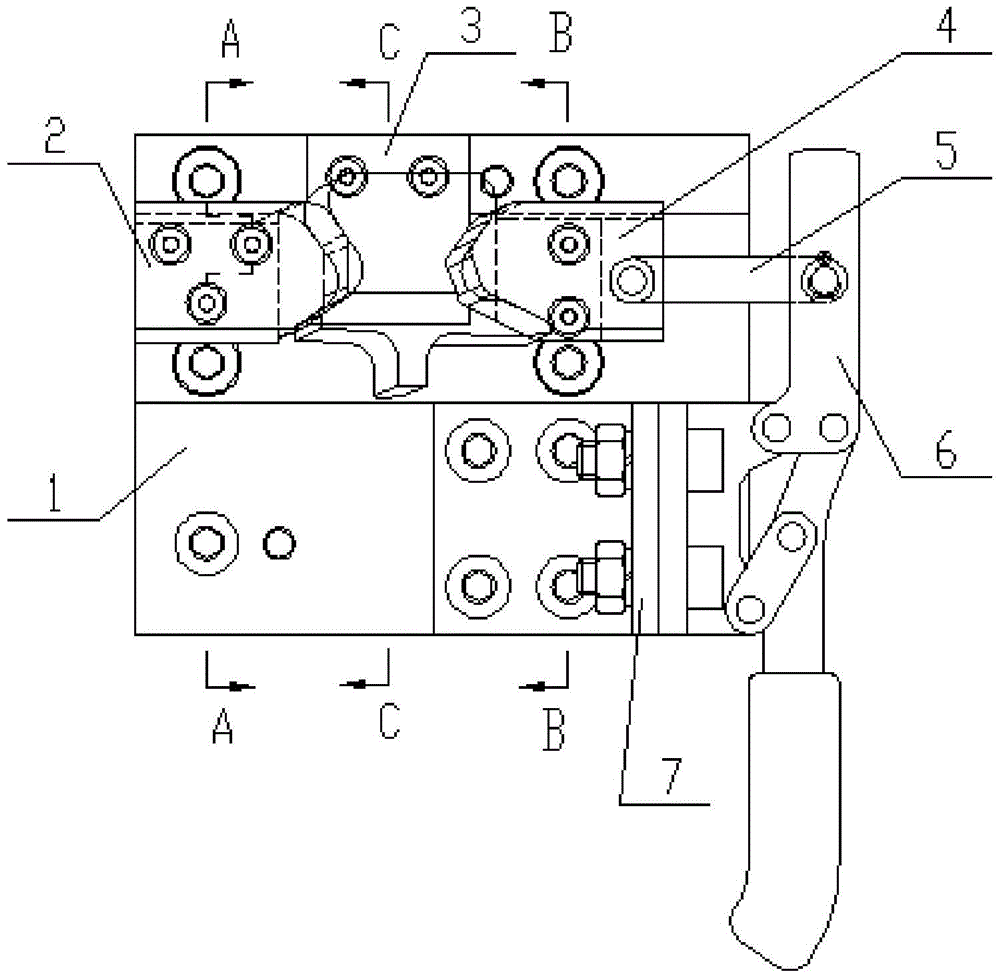

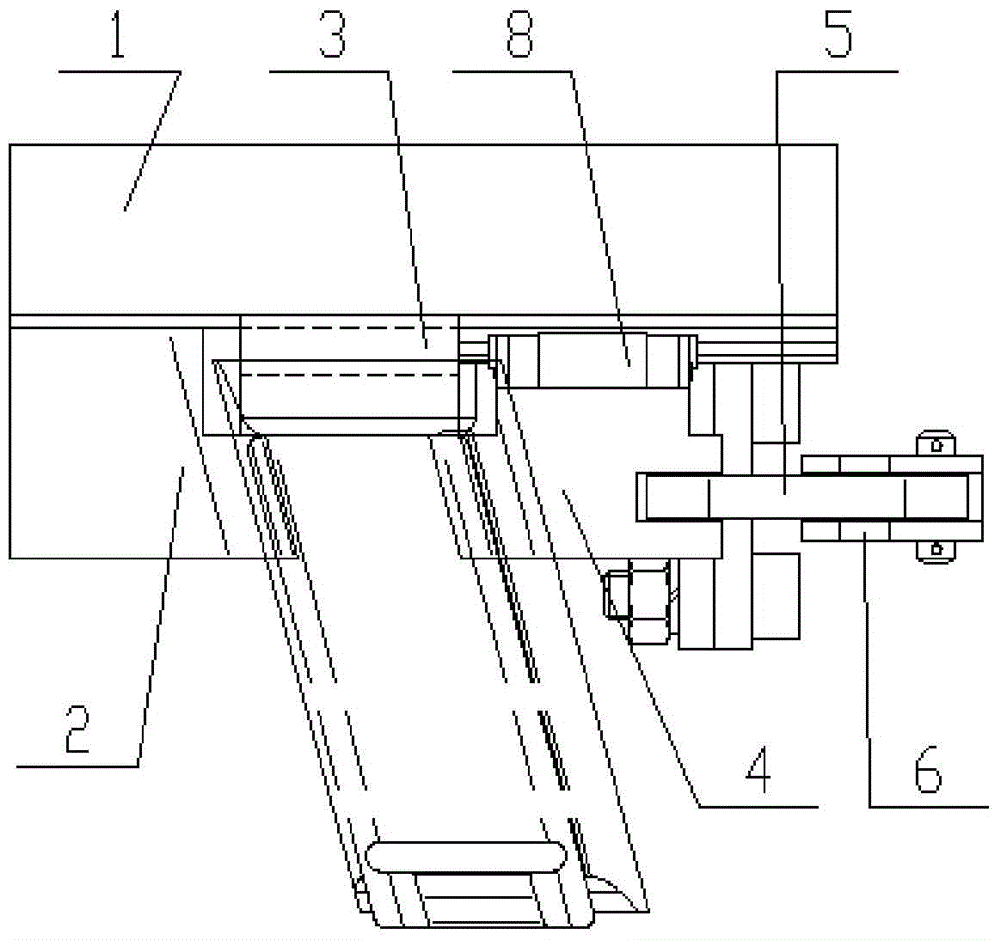

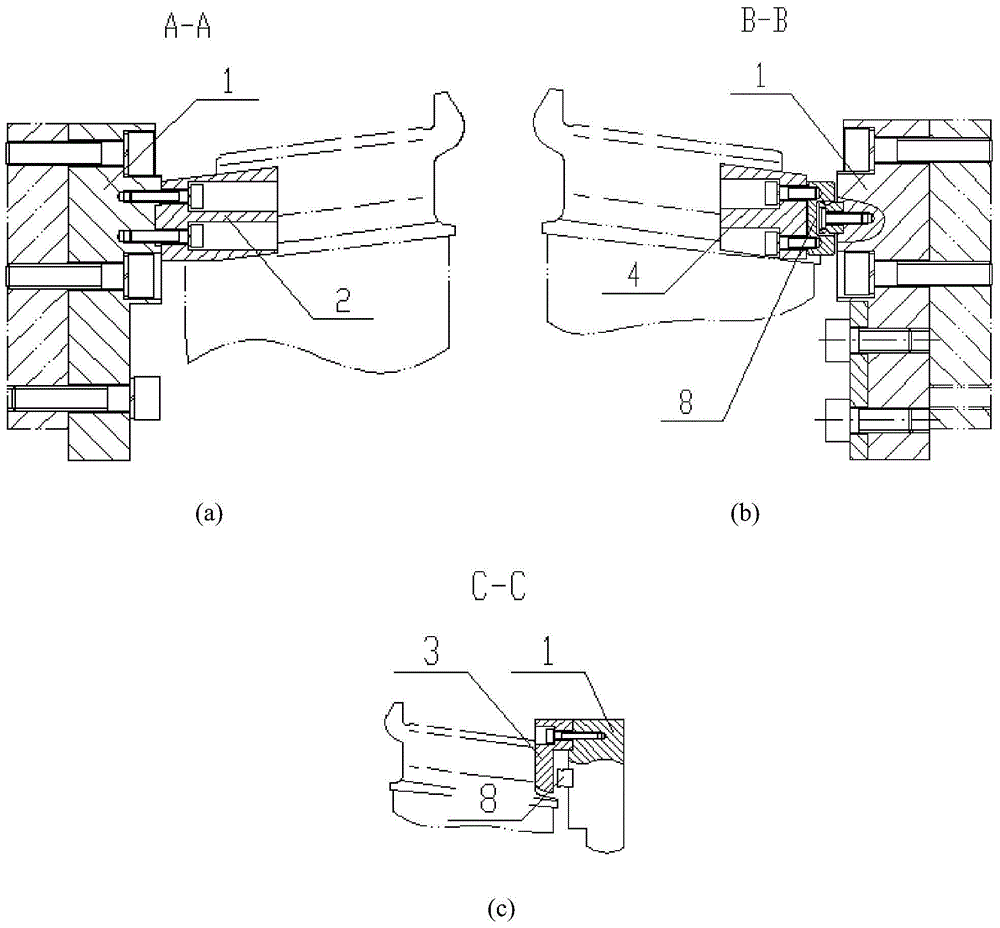

[0027] see Figure 1-5 , the present invention includes a mounting seat 1 provided with a boss surface, and a keyway is opened on the boss surface of the mounting seat 1; several threaded holes 11 and pin holes 12 for connecting with other equipment are provided on the mounting seat 1. The mounting base 1 is provided with a fixed clamping block 2, a positioning block 3 and a sliding clamping block 4 in sequence along the keyway. The sliding clamping block 4 is fixed with a linear bearing 8 for driving it to slide in a straight line, and the sliding clamping block 4 is fixed on a straight line by bolts. On the bearing 8, the linear bearing 8 is fixed on the mounting seat 1.

[0028] see Figure 9 , 11, the sliding clamp block 4 is movably connected to the quick clamp 6 through the slider connecting rod 5, the end of the quick clamp 6 has a corner, and one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com