A special tooling for gamma ray detection of small-diameter pipe butt joints

A technology of gamma ray and butt joints, which is applied in the direction of material analysis using radiation, can solve the problems of inaccurate positioning, difficulty in selecting the focal length, and low sensitivity, and achieve the effects of flexible tooling, improved detection efficiency, and reduced radiation emphasis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further explained below in conjunction with the accompanying drawings. But the protection scope of the present invention is not limited to specific implementation manners.

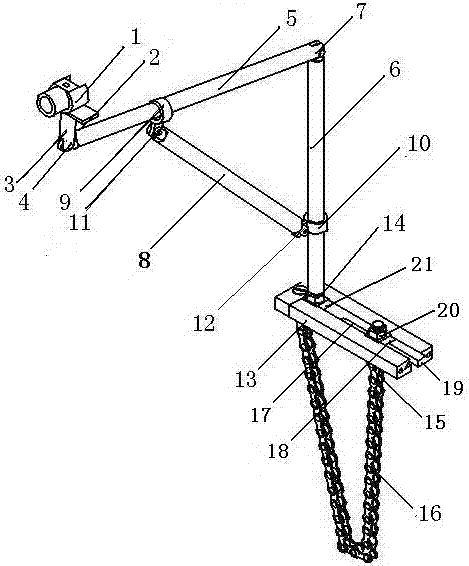

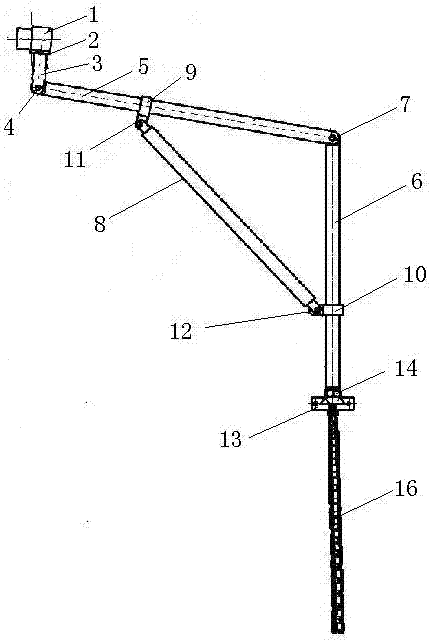

[0057] A gamma ray detection special tooling for butt joints of small-diameter pipes of the present invention includes: a gamma source fixing mechanism, an adjusting mechanism, and a fastening mechanism;

[0058] The gamma source fixing mechanism includes a fixing sleeve 1, a lead shield fixing plate 2, a source support arm 3, and fastening bolts. The fixing sleeve 1 is used to fix the gamma source, and the outer edge is provided with screw holes, and the fastening bolts are set on The screw hole is used to fix the gamma source in the fixed sleeve 1. The entrance of the gamma source of the fixed sleeve 1 is also provided with a fixing slot for the exposure head, so that the rectangular nut at the end of the source tube enters the exposure head. In the fixed card slot, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com