Water-blocking cable paste filling device and filling method for optical cable strength member

A technology of water-blocking cable paste and filling device, which is applied to optical components, light guides, optics, etc., can solve the problems of emptying around the optical cable strength, impact on the overall performance of the optical cable, insufficient filling of cable paste, etc., to achieve no power consumption, prevent The effect of unstable water seepage and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

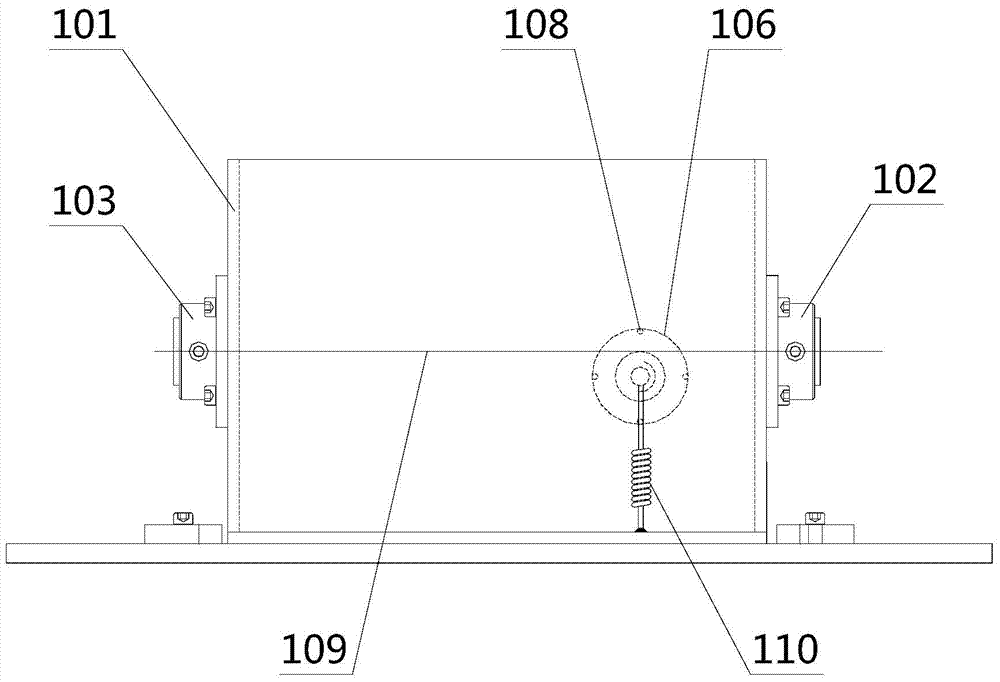

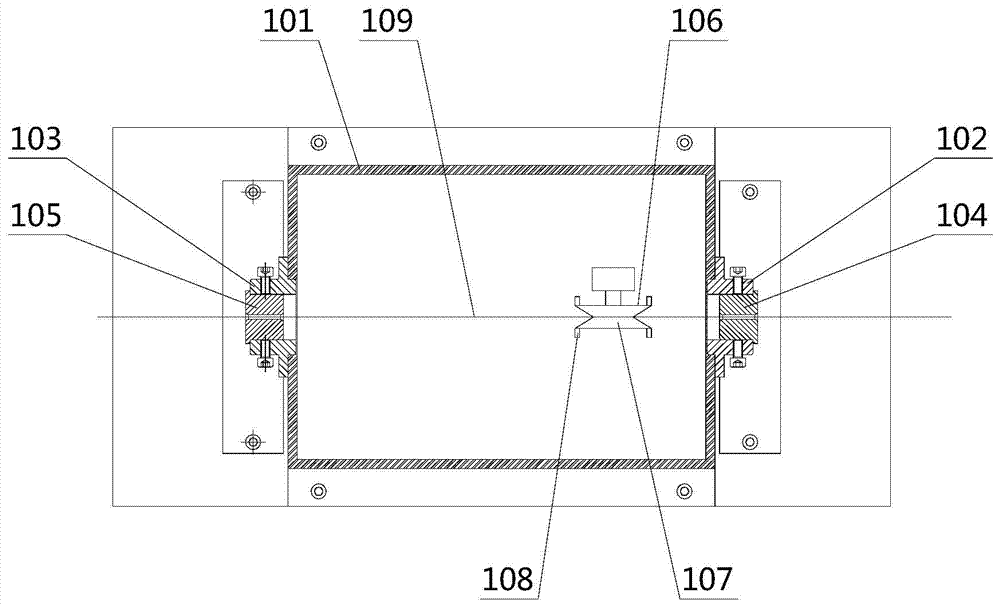

[0044] see figure 1 with figure 2 , this embodiment provides a water-blocking cable paste filling device for an optical cable reinforcement, the water-blocking cable paste filling device for an optical cable reinforcement includes a hollow paste storage box 101 and a cable paste stirring device arranged in the paste storage box 101 .

[0045] The paste storage box 101 is provided with a cable paste control mold base, and the cable paste control mold base includes a front cable paste control mold base 102 and a rear cable paste control mold base 103 respectively arranged at two ends of the paste storage box 101 .

[0046] The front cable paste control mold seat 102 is provided with the front cable paste control mold 104, the rear cable paste control mold seat 103 is provided with the rear cable paste control mold 105, and the front cable paste control mold 104 and the rear cable paste control mold 105 are respectively provided with A through hole communicating with the inner...

no. 2 example

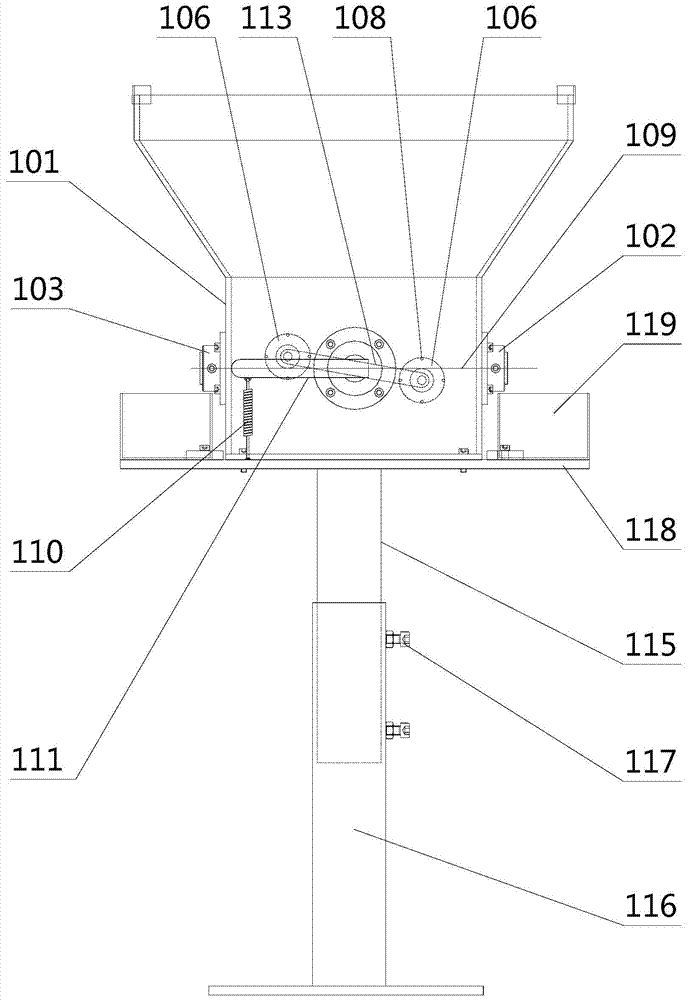

[0056] see image 3 with Figure 4 The basic structure, principle and technical effect of the water-blocking cable paste filling device for optical cable reinforcement provided by this embodiment are the same as those of the first embodiment. For a brief description, what is not mentioned in this embodiment can be Refer to the corresponding content in the first embodiment.

[0057] see image 3 with Figure 4 , In this embodiment, the spring 110 is indirectly connected to the stirring guide wheel 106 . The tensioning device further includes a connecting rod 111 , a rotating shaft 112 and a swing rod 113 . The spring 110 is arranged outside the paste storage box 101. One end of the connecting rod 111 is connected to the spring 110, and the other end is connected to the rotating shaft 112. The end of the rotating shaft 112 away from the connecting rod 111 extends into the paste storage box 101 and is connected to the swing rod 113. The rotating shaft 112 cooperates with the...

no. 3 example

[0075] This embodiment provides a water-blocking cable paste filling method for an optical cable strength member. The method uses the water-blocking cable paste filling device for an optical cable strength member provided in any of the above-mentioned embodiments. The specific steps of the method are as follows:

[0076] see Figure 1 ~ Figure 4 Install the front cable paste control mold 104 in the front cable paste control mold seat 102, install the rear cable paste control mold 105 in the rear cable paste control mold seat 103, and pass the optical cable reinforcement 109 through the rear cable paste control mold 105 in sequence The through hole on the top, the paste storage box 101 and the guide wheel groove 107 on the stirring guide wheel 106, and pass through the through hole of the front cable paste control mold 104, so that the optical cable reinforcement 109 is in contact with a point on the guide wheel groove 107 circumference, The tensioning device tensions the optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com