nox measurement system and method

A measurement system and measurement pipeline technology, applied in the field of NOx measurement system, can solve the problems of shortening the service life of NOx sensors, blockage of bypass pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

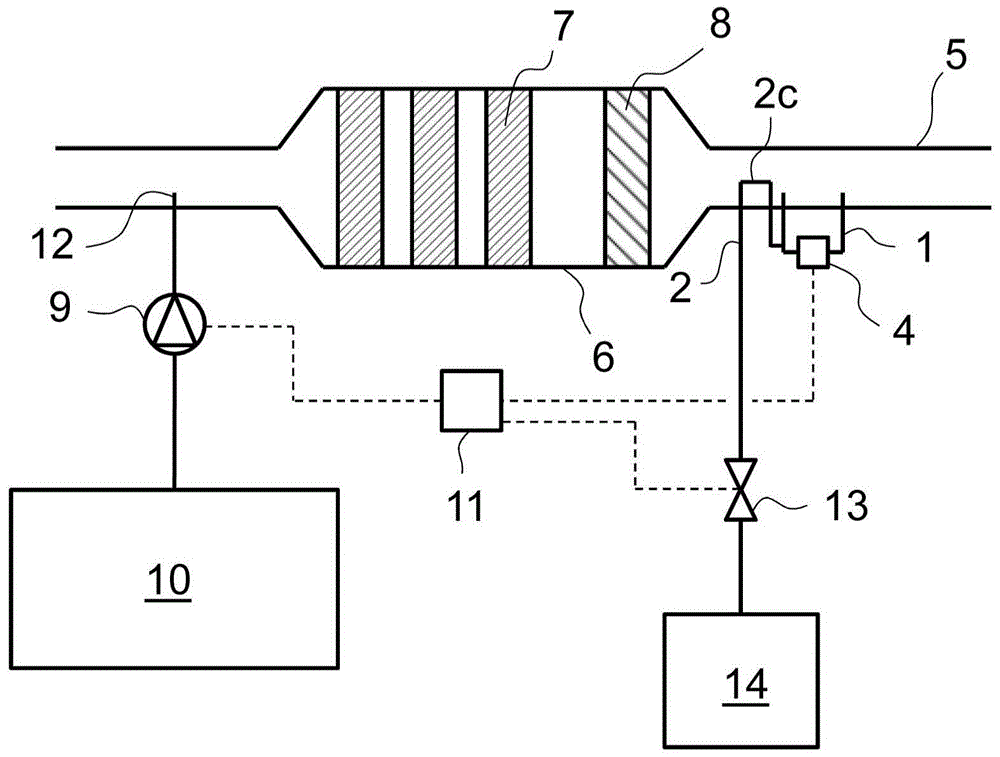

[0014] exist figure 1 , a simplified schematic diagram of a selective catalytic reduction (SCR) system of an internal combustion engine is shown. The SCR system is particularly suitable for large piston engines, such as the main or auxiliary engines of ships or engines used in power plants to generate electricity. The system includes a catalytic converter 6 with three SCR elements 7 . The SCR element 7 is a ceramic honeycomb structure coated with catalyst material. Urea, which is used as a reducing agent, is injected into the exhaust gas flow upstream of the catalytic converter 6 via a reducing agent injector 12 . Urea is stored in tank 10 and the correct amount of urea solution is delivered to reductant injector 12 using metering pump 9 . The control unit 11 is arranged to control the metering pump 9 . The urea injected into the exhaust system mixes with the exhaust gas and is decomposed into ammonia and carbon dioxide due to the heat of the exhaust gas. On the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com