Partition wall system including clamping of the panels

A panel, elastic clamping technology, applied in the direction of wall, window glass installation, parallel glass structure, etc., can solve the problem of incompatibility between size and material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

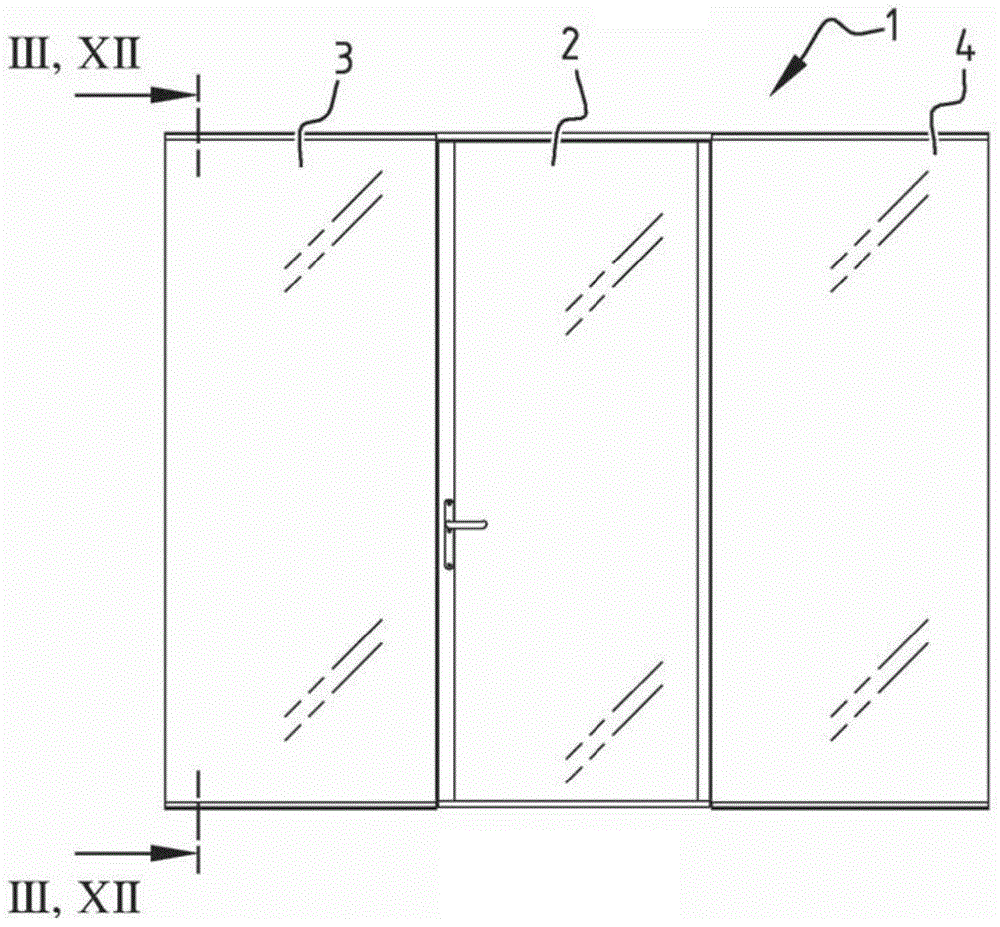

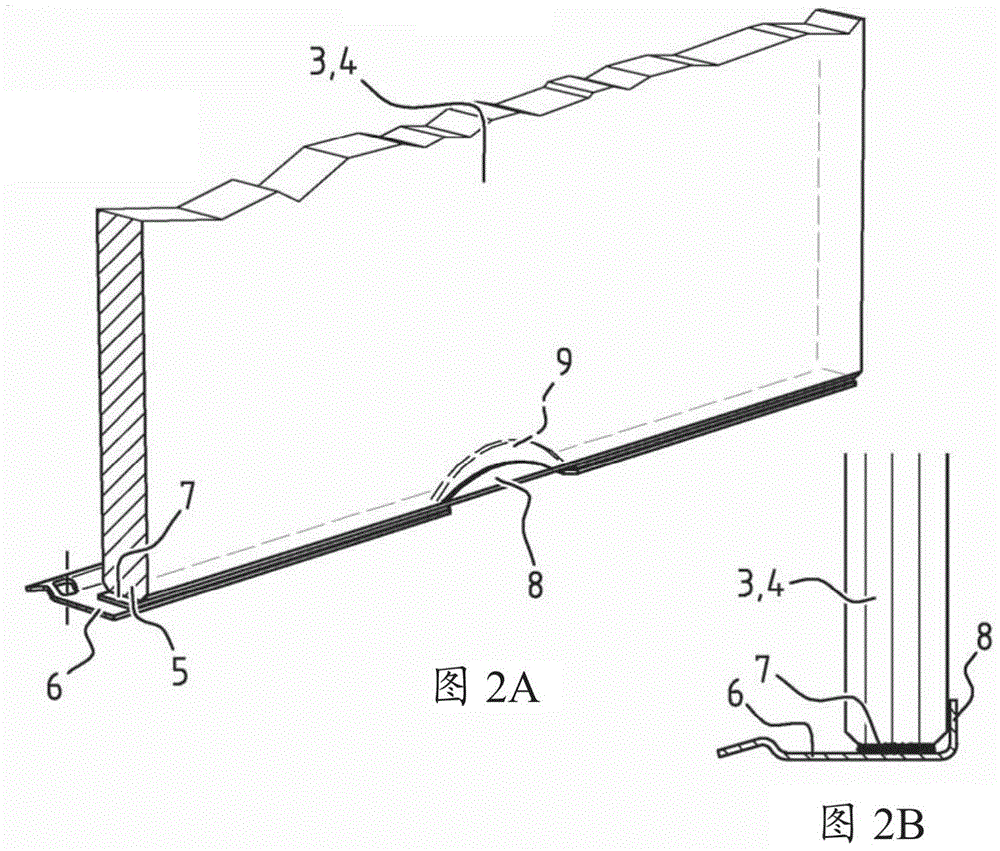

[0024] exist figure 1 In , a partition wall 1 designed for partitioning accessible spaces in a building is shown, made (for simplicity) of only one door 2 provided with glass panels 3 , 4 on both sides. As will still be explained below, each glass panel 3, 4 is provided at its bottom edge 5 with a lip 6 which extends inwardly (Fig. 2). The lip 6 extends along the entire width of the glass panel 3 , 4 and is fixed to the glass panel 3 , 4 via an adhesive strip 7 . The lip 6 is also flanged along part of its length, so that its flanged portion 8 protrudes into a corresponding shaped groove 9 ( FIG. 2 a ) of the glass pane 3 , 4 . It is pointed out that the glass panels 3, 4 are constructed in the same way on their upper sides, ie are also provided with a partially flanged lip 6, as image 3 shown. Figure 2b shows that the lip 6 is flanged along its entire length, the flanged edge 8 abutting the vertical side surfaces of the glass panels 3,4.

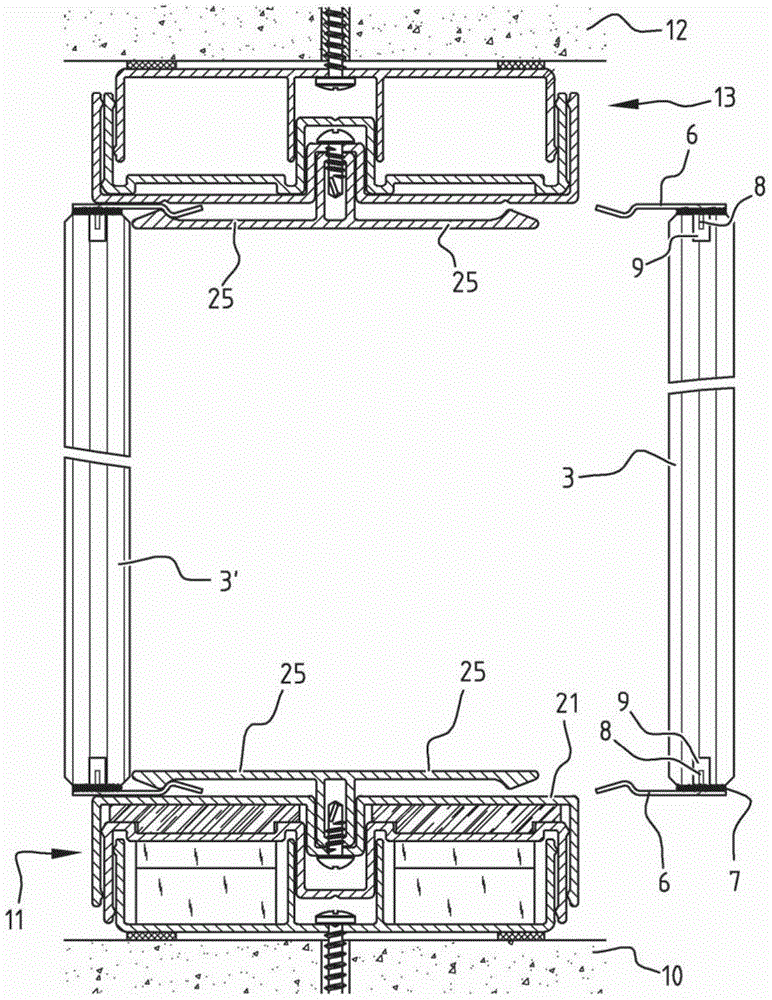

[0025] now refer to Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com