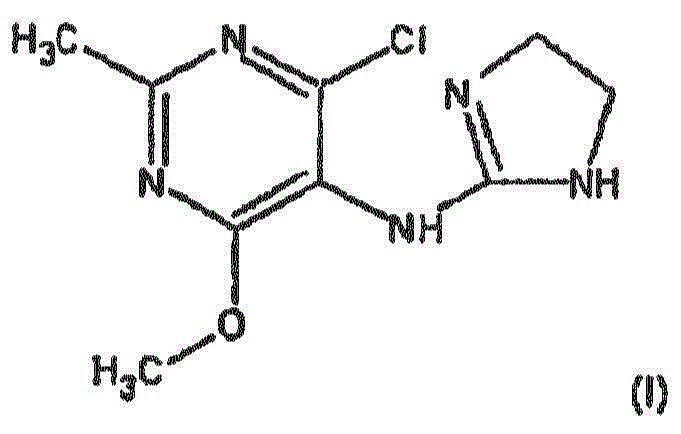

Improved process for the manufacture of moxonidine

A mixture and technology within minutes, applied in the direction of organic chemistry, etc., can solve the problems of no public synthesis method of moxonidine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

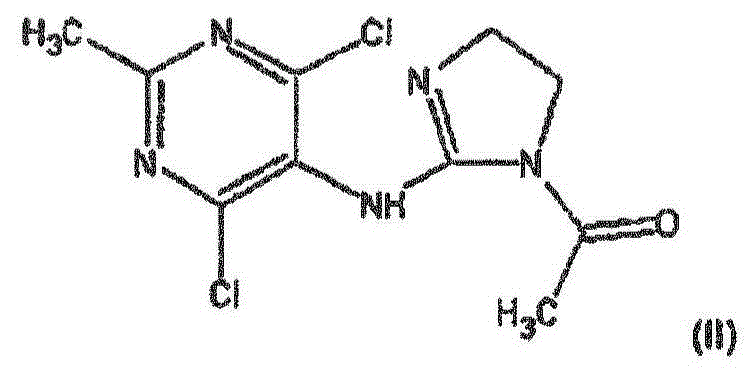

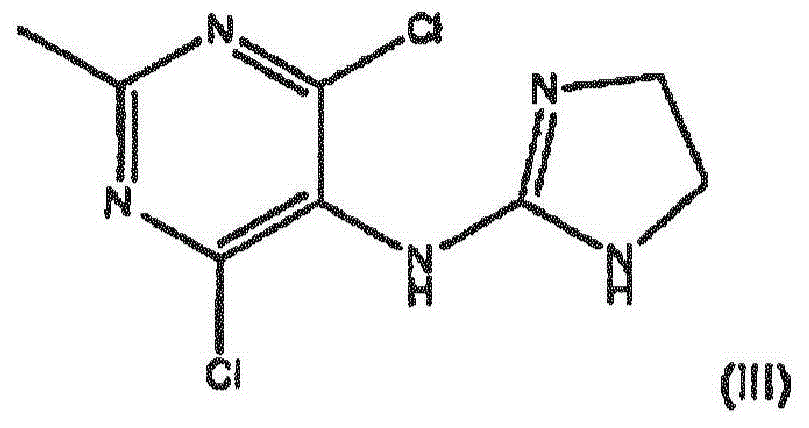

Problems solved by technology

Method used

Image

Examples

Example

[0053] Preparation Examples 1 to 3 Preparation of Moxonidine

[0054] 102 kg (128 L, 3014.4 mol) of methanol and 7.7 kg (55.6 mol) of potassium carbonate were injected into the reactor, and the mixture was vigorously stirred and heated to 65°C. 8kg DMAIA (27.8mol) was divided into 8 portions and added within 20 minutes. The contents of the reactor were kept at 65°C with stirring for an additional 7 to 12 minutes. The reaction was stopped by transferring the entire reaction mixture to a separate pre-cooled reactor in less than 1 minute and further cooling the reaction mixture to below 25°C in 20 minutes.

[0055] work process:

[0056] The pH value is adjusted to pH≤7 with acetic acid. The reaction mixture is optionally filtered through activated carbon. Then the pH of the filtrate was adjusted to pH ≥ 8 with aqueous ammonia solution, and moxonidine was separated, washed with water and methanol, and dried.

[0057] Yield: Theoretically 92.0%

[0058] Table 1: Moxonidine impuritie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com