Environment-friendly polyolefin cable material for power field and production method of environment-friendly polyolefin cable material

A production method and technology of polyolefin, which can be used in circuits, electrical components, plastic/resin/wax insulators, etc., and can solve problems such as poor mechanical properties and poor flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A kind of environment-friendly polyolefin cable material used in the electric power field, its raw material mass percentage is:

[0063]

[0064]

[0065] The polyolefin is a mixture of 1-hexene, 1-octene and 4-methyl-1-pentene, and the mass ratio of the three is 1:1:1.

[0066] The invention discloses a production method of an environment-friendly polyolefin cable material used in the electric power field. The environment-friendly polyolefin cable material can be obtained by mixing and granulating various raw materials.

[0067] A flame-retardant polyolefin masterbatch is composed of flame-retardant capsules and polyolefin particles, wherein the mass fraction of the flame-retardant capsules in the flame-retardant polyolefin masterbatch is 3%, and the two raw materials are melted and granulated.

[0068] A preparation method of flame retardant capsules, the concrete steps are:

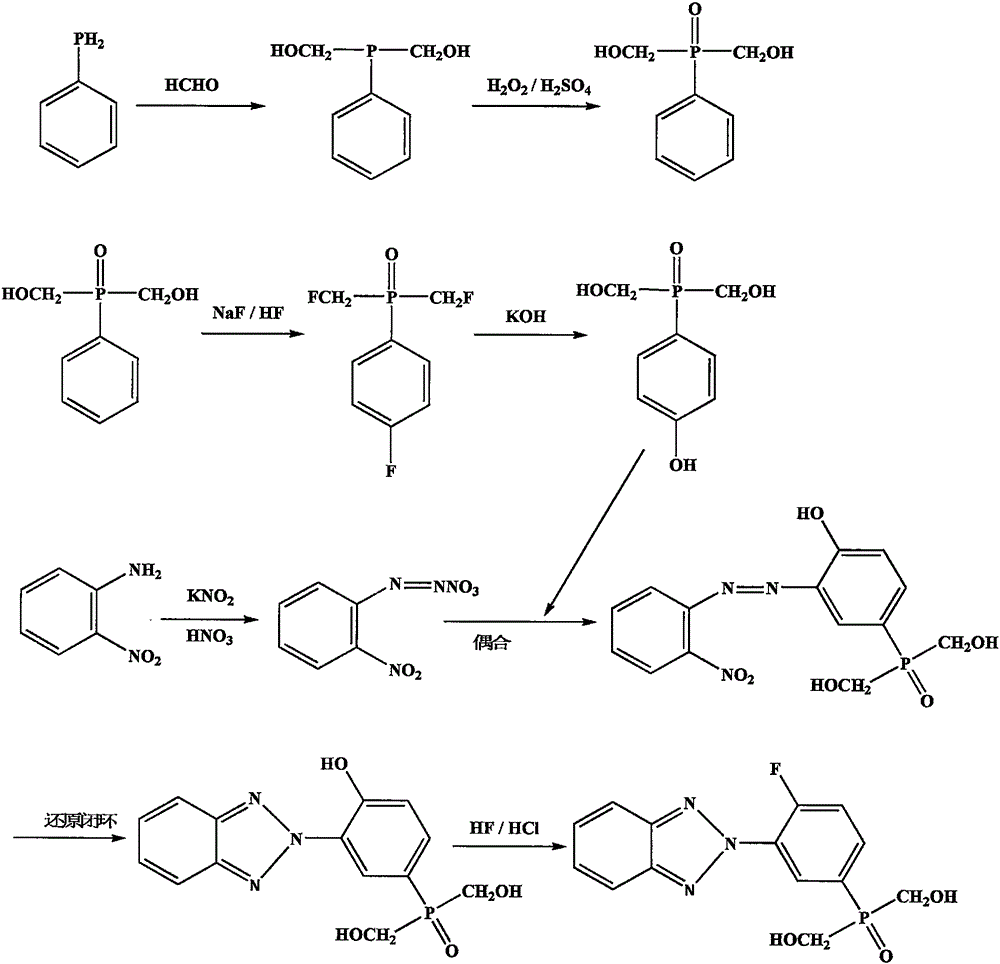

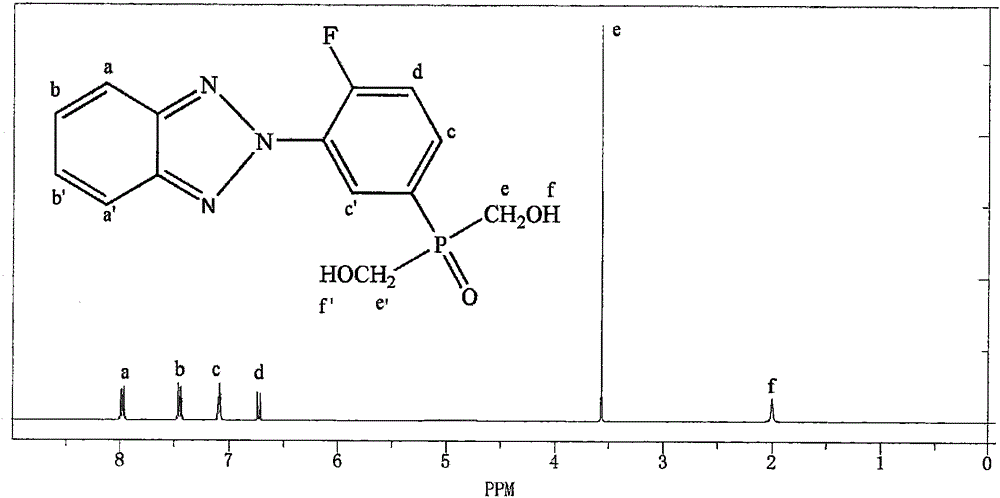

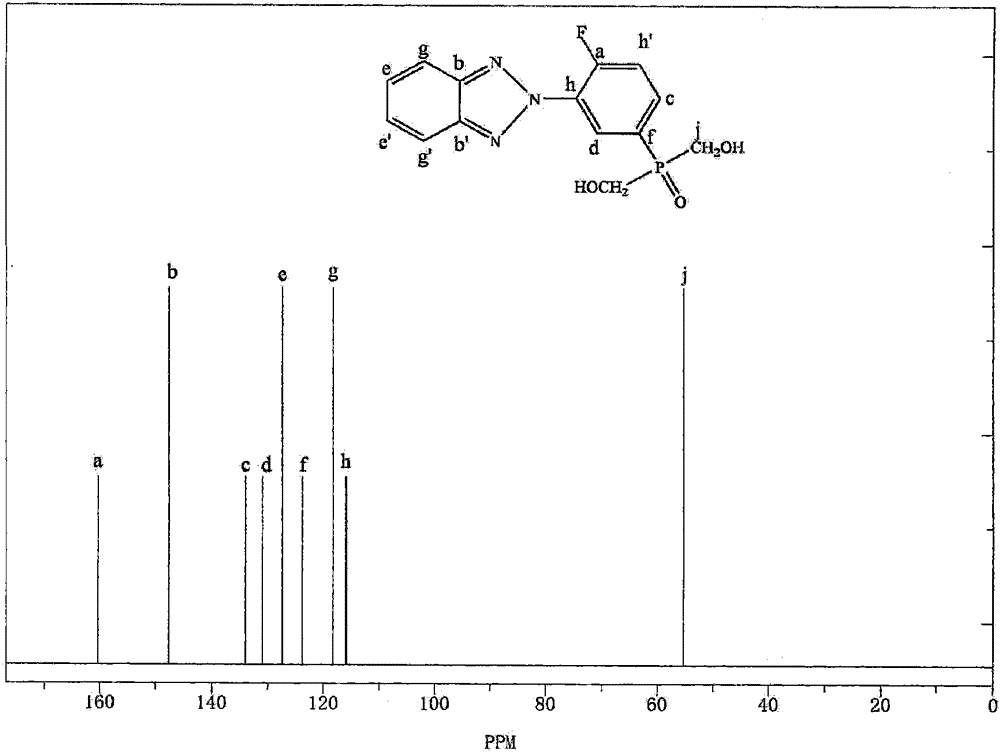

[0069] (a) preparation of p-dihydroxy p-phenol phosphine

[0070] Using the aqueous ...

Embodiment 2

[0094] A kind of environment-friendly polyolefin cable material used in the electric power field, its raw material mass percentage is:

[0095]

[0096] The polyolefin is a mixture of 1-hexene, 1-octene and 4-methyl-1-pentene, and the mass ratio of the three is 1:1:1.

[0097] The invention discloses a production method of an environment-friendly polyolefin cable material used in the electric power field. The environment-friendly polyolefin cable material can be obtained by mixing and granulating various raw materials.

[0098] A flame-retardant polyolefin masterbatch is composed of flame-retardant capsules and polyolefin particles, wherein the mass fraction of the flame-retardant capsules in the flame-retardant polyolefin masterbatch is 5%, and the two raw materials are melted and granulated.

[0099] A preparation method of flame retardant capsules, the concrete steps are:

[0100] (a) preparation of p-dihydroxy p-phenol phosphine

[0101] Using the aqueous solution of ...

Embodiment 3

[0121] A kind of environment-friendly polyolefin cable material used in the electric power field, its raw material mass percentage is:

[0122]

[0123] The polyolefin is a mixture of 1-hexene, 1-octene and 4-methyl-1-pentene, and the mass ratio of the three is 1:1:1.

[0124] The invention discloses a production method of an environment-friendly polyolefin cable material used in the electric power field. The environment-friendly polyolefin cable material can be obtained by mixing and granulating various raw materials.

[0125] A flame-retardant polyolefin masterbatch is composed of flame-retardant capsules and polyolefin particles, wherein the mass fraction of the flame-retardant capsules in the flame-retardant polyolefin masterbatch is 7%, and the two raw materials are melted and granulated.

[0126] A preparation method of flame retardant capsules, the concrete steps are:

[0127] (a) preparation of p-dihydroxy p-phenol phosphine

[0128] Using the aqueous solution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com