Hollow structure

A structure and hollow technology, which is applied in the field of hollow structures of cores and sheets, can solve the problems of difficulty in printing on the surface of the synthetic resin sheet 104, and reduced appearance aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described based on the embodiments shown in the drawings.

[0032] based on Figure 1 to Figure 8 The hollow structure according to the first embodiment of the present invention will be described.

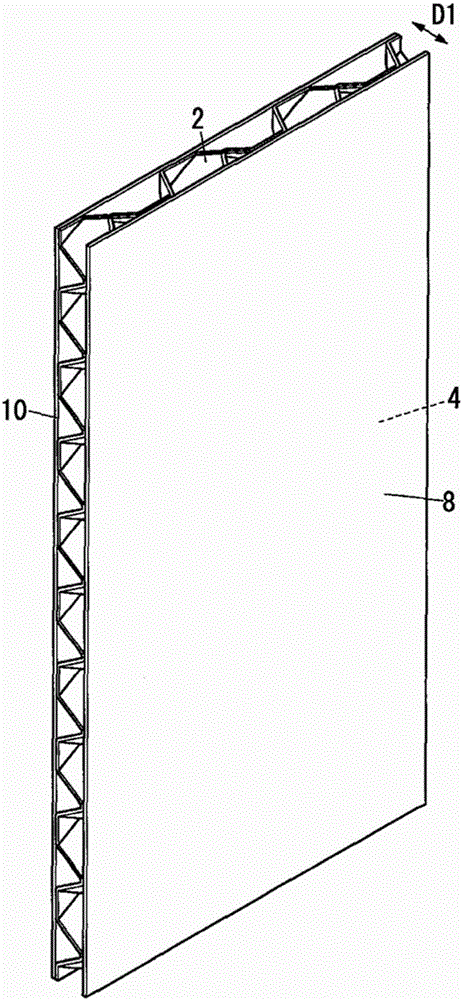

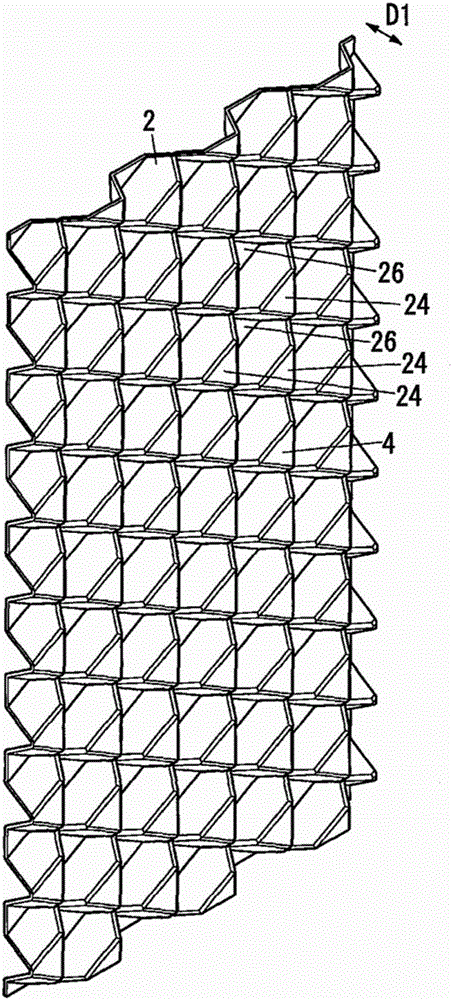

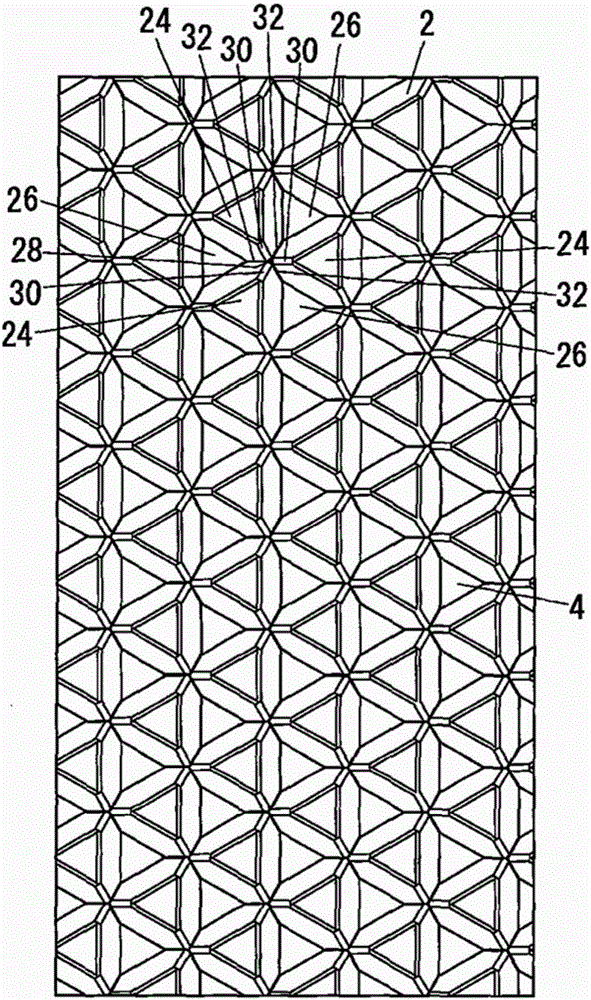

[0033] figure 1 It is a perspective view of the hollow structure of this embodiment. The hollow structure of this embodiment is a panel-shaped hollow structure. In the hollow structure of this embodiment, the first sheet 8 made of synthetic resin is pasted on the Figure 2 to Figure 5 As shown on the first surface 4 of the core material 2 made of synthetic resin, the second sheet material 10 made of synthetic resin is pasted on the second surface 6 of the core material 2 .

[0034] The materials of the core material 2 , the first sheet 8 and the second sheet 10 can be polypropylene, polyethylene, polycarbonate, polylactic acid and the like. The materials of the core material 2, the first sheet 8, and the second sheet 10 may be different fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com