Anti-dragging device with vortex forming anti-dragging shell pieces

A technology of drag reduction device and casing, which is applied in the direction of drag reduction, transportation and packaging, and by generating vortex, which can solve the problems such as little room for improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

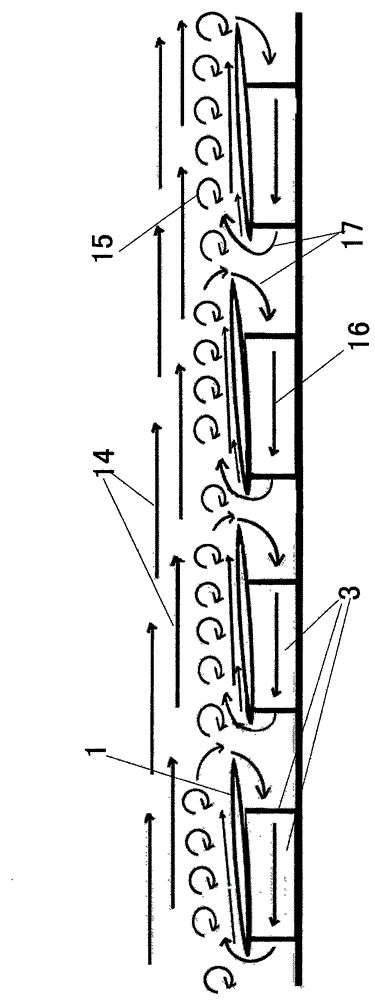

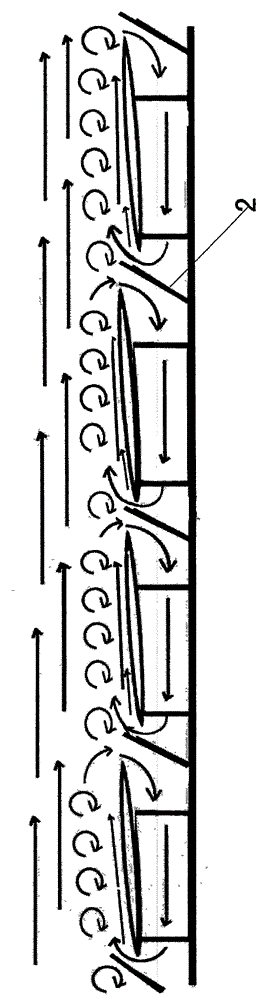

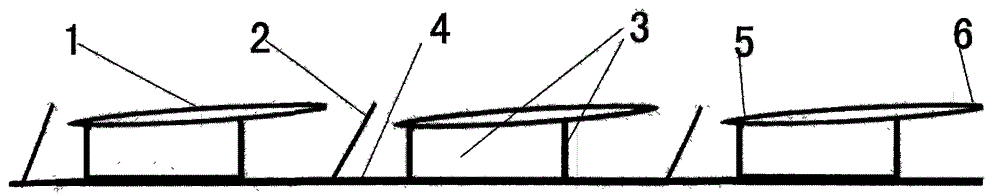

[0030] The most important of all kinds of drag reduction devices with vortex drag reduction shells are manufactured or installed on the outer surfaces of aircraft, missiles, space rockets, torpedoes, submarines, and the outer surfaces of various ships below the water surface line. The characteristic is that the various vortex-forming drag-reducing shells in the drag-reducing device are not directly attached to the outer surfaces of the machine, bomb, arrow, mine, boat, and ship inside, but the discrete vortex The drag-reducing shell pieces (1, 18-25), or the integrated vortex-shaped drag-reducing shell piece strips formed by their interconnection, are made or fixed at a certain interval on aircraft, bombs, arrows, mines, boats, boats, etc. On the outer surface, install the outermost part of the fixed base (3), or the shuttle-like protrusion (26), the strip-shaped raised strip (8), the shuttle-like raised strip (27), or The position near the top of the outer side is installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com