Worm shaft

A technology of worm shaft and worm gear, applied in the field of worm shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

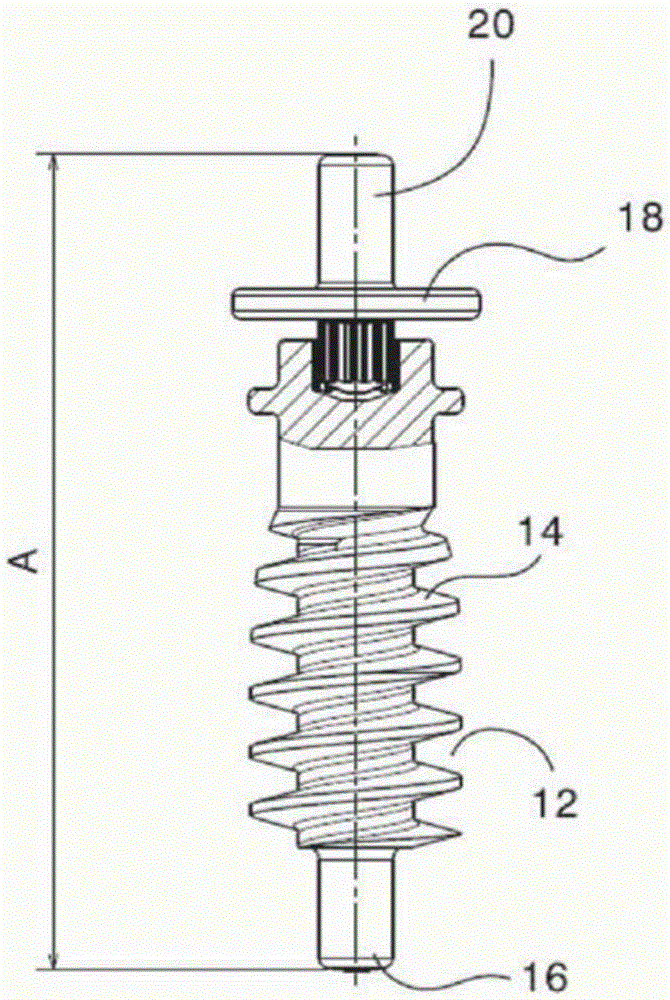

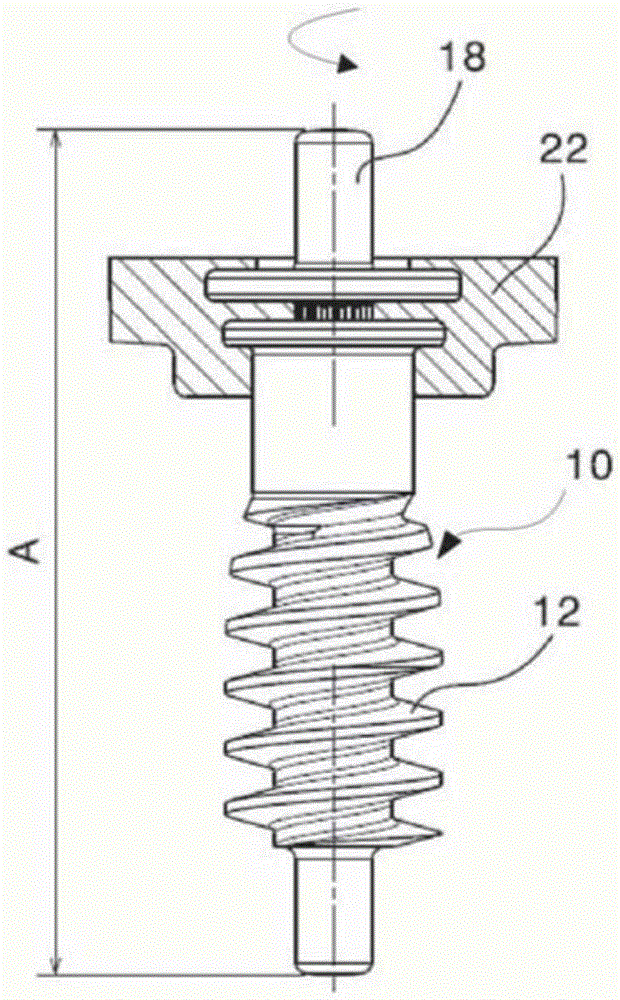

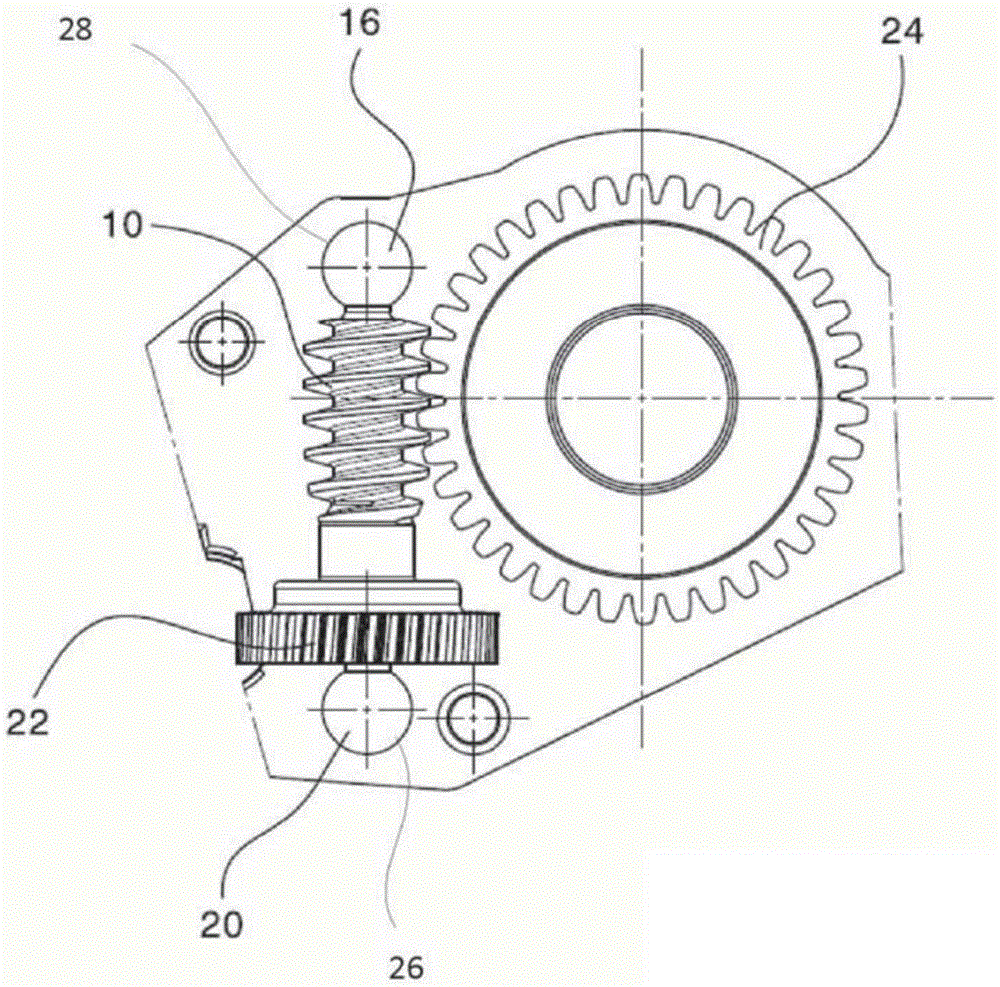

[0028] figure 1 is a schematic view of a first part and a second part of a worm shaft 10 according to the invention. The first part 12 includes threads 14 . A bearing pin 16 is provided at the end of the first worm shaft. The end of the worm shaft facing away from the first part has a second part 18 ; the second part is provided with a bearing pin 20 . The first part 12 and the second part 18 are arranged such that the end of the first bearing pin 16 and the end of the second bearing pin 20 are spaced apart from each other by a predetermined axial extension A length of the worm shaft. Such as figure 2 As shown in more detail in , the first part 12 and the second part 18 are thus tightly connected to each other in relative positions, and finally determine the axial extension A length of the worm shaft 10 .

[0029] In this way, the first part 12 and the second part 18 can be produced for a plurality of different axial extension A lengths without any adaptation; this is bec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com