Quick-fit hydraulic or hydrodynamic coupling for pressurised fluids

A technology for pressurizing fluids, couplers, applied in connections with fluid cut-off devices, valve operation/release devices, couplings, etc., to solve problems such as unavoidable risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

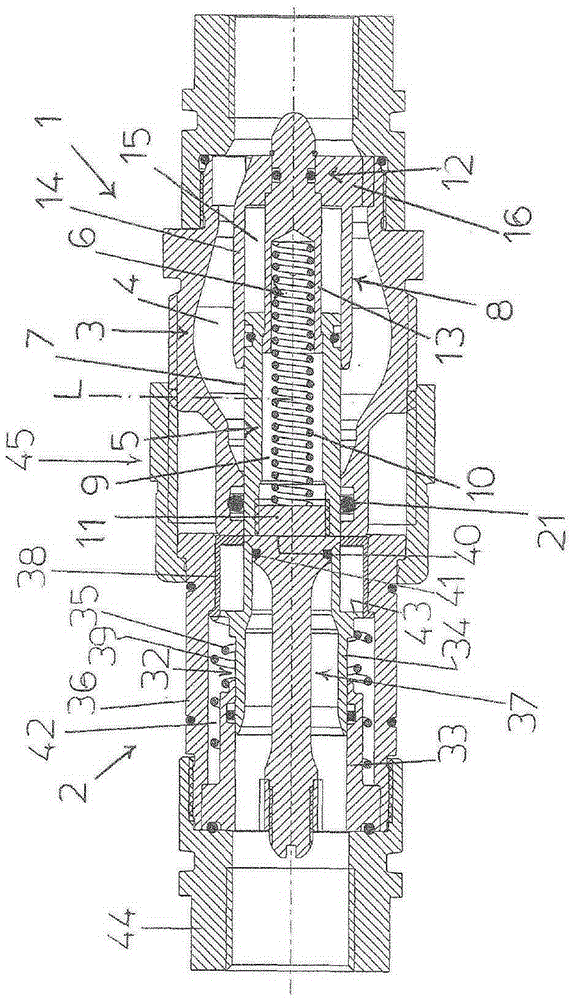

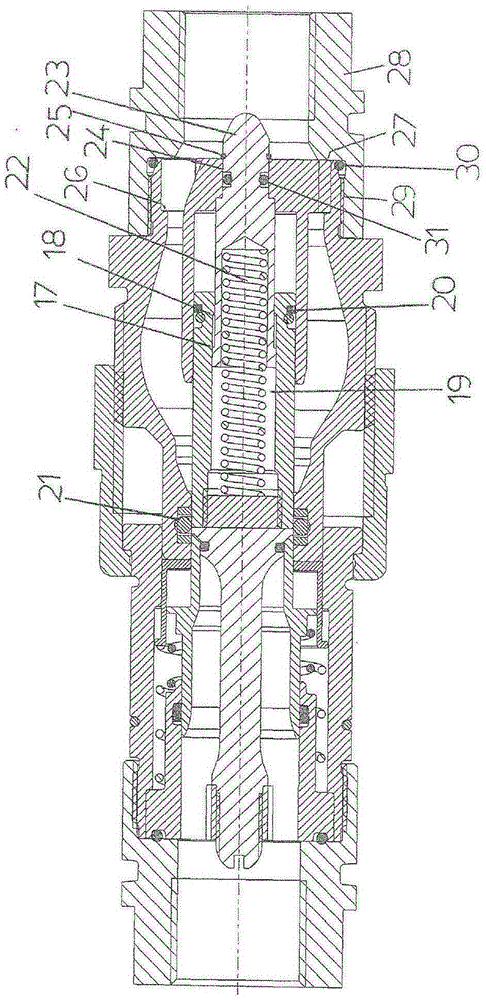

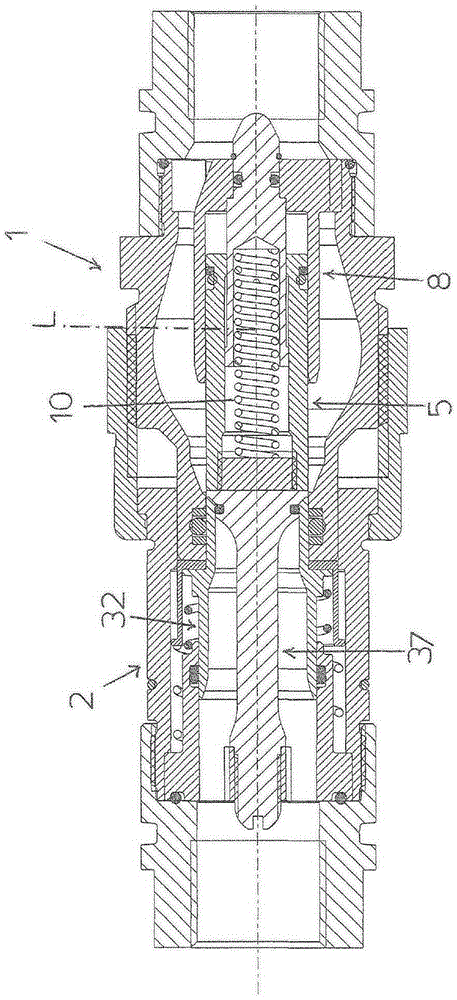

[0023] Referring to the figures cited above, there is shown a male quick-fit hydraulic or hydrodynamic coupler 1 and a female quick-fit hydraulic or hydrodynamic coupler 2 .

[0024] Male coupling 1 comprises: a valve body 3 extending along a longitudinal axis L and having a cavity 4 extending axially over the entire length of the valve body; and a shutter rod 5 coaxial with axis L Positioned in the cavity 6 and capable of opening the axial passage of the fluid through the cavity 4 opposite to and by means of the action of at least one elastic element 6 with respect to the valve body 3 along the axis L and a position for closing the axial passage of the fluid through the cavity 4.

[0025] In the position for closing the passage, the head end of the rod 5 and the head end of the valve body 3 are in hydraulic-tight contact along the periphery via the seal 21 .

[0026] In the position where the passage is opened by the effect of the relative movement between the rod 5 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com