Patents

Literature

30 results about "Hydromechanical coupling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

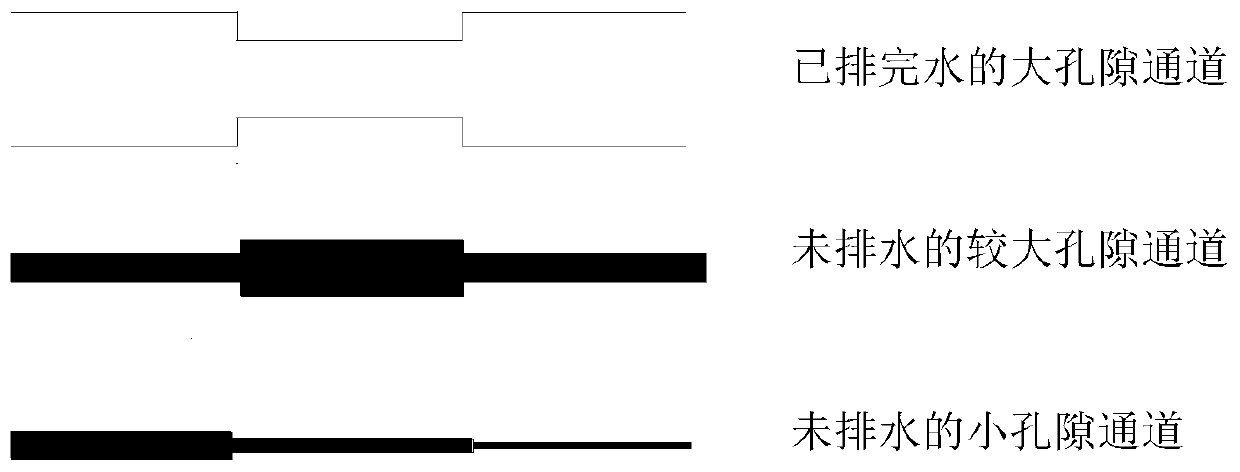

Micropore channel-based saturated/unsaturated osmotic coefficient forecasting method

ActiveCN107063967AFit closelySimple calculationPermeability/surface area analysisPredictive methodsOsmotic coefficient

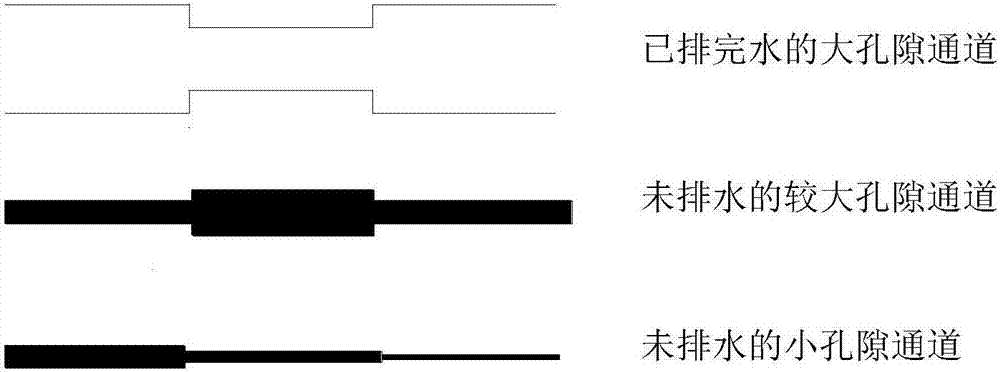

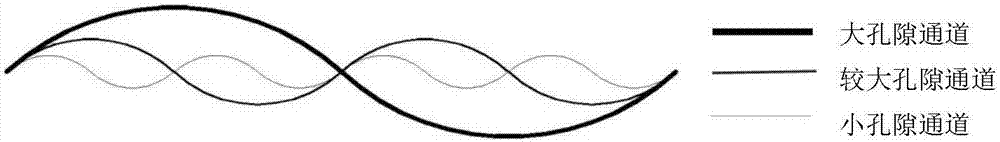

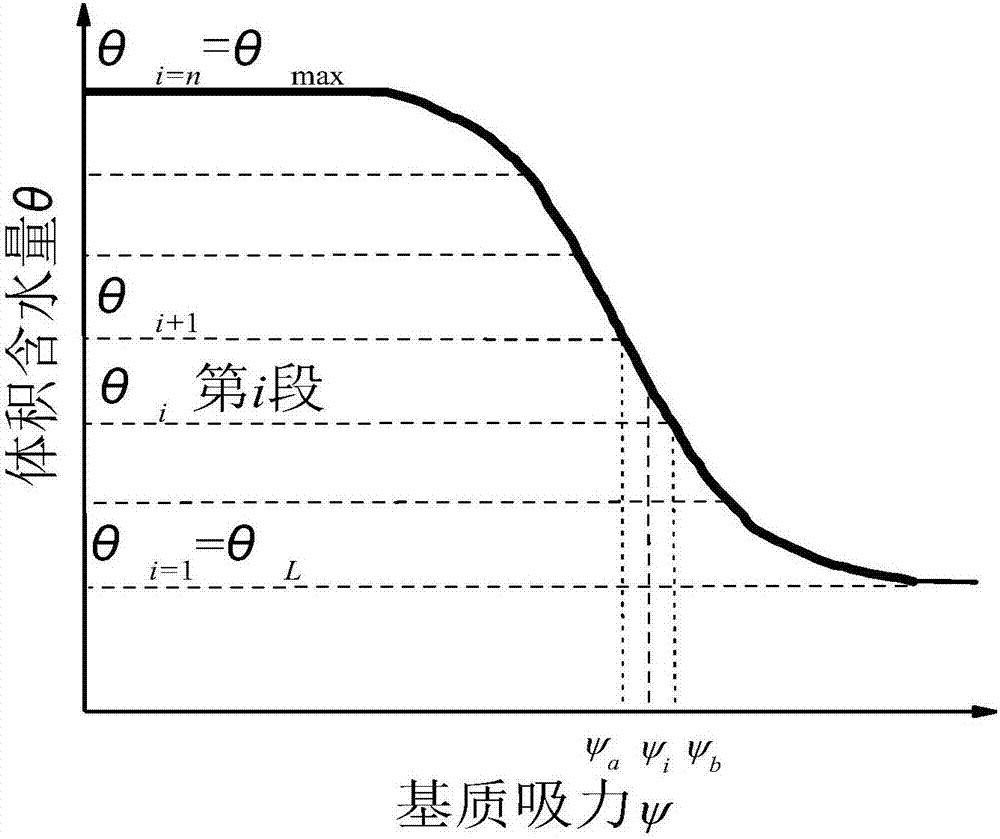

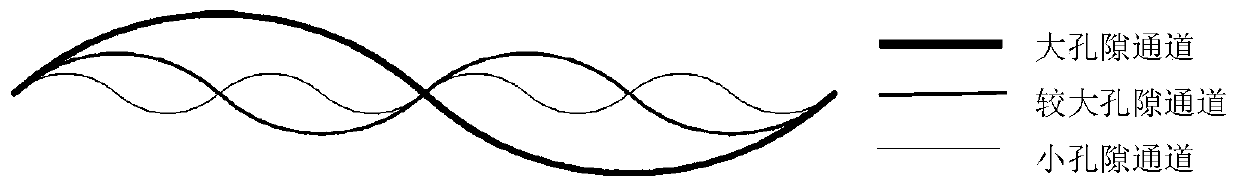

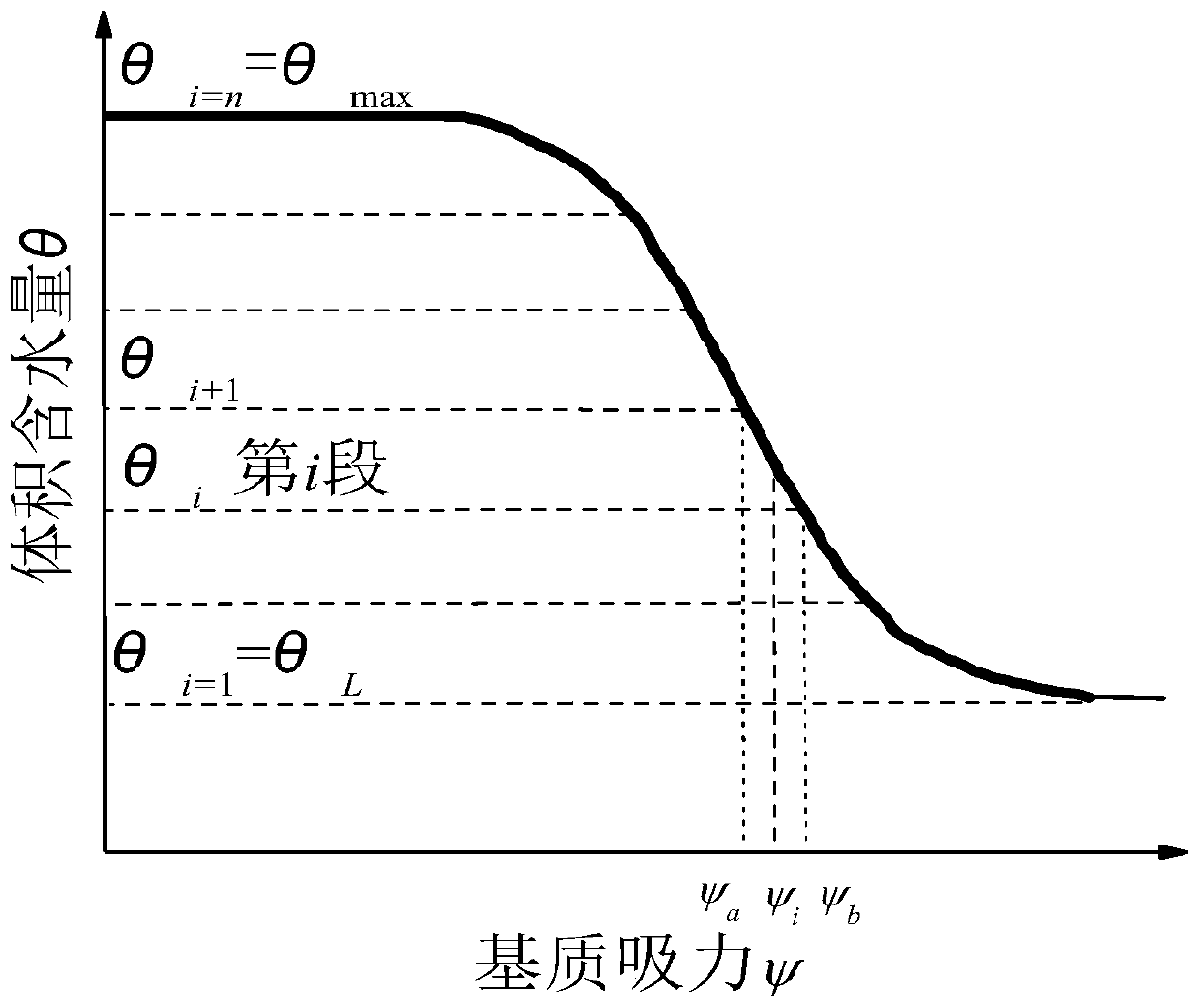

The invention relates to a micropore channel-based saturated / unsaturated osmotic coefficient forecasting method, which comprises the following steps: on the basis of a micro-connected channel seepage model and the capillary theory, building a model for forecasting a saturated / unsaturated osmotic coefficient through soil-water characteristic curves; obtaining the soil-water characteristic curve and a saturated osmotic coefficient of soil through a pressure plate apparatus and a varying head test; calculating a comprehensive osmotic ratio constant kc by using the model of the saturated osmotic coefficient; performing n equal division according to the comprehensive osmotic ratio constant kc of a certain type of soil and the actually measured soil-water characteristic curve, and calculating a saturated osmotic coefficient ks and an unsaturated relative osmotic coefficient kr of the type of soil by using the relevant model; multiplying the saturated osmotic coefficient ks and the unsaturated relative osmotic coefficient kr, thus obtaining an unsaturated osmotic coefficient kw. From a microscopic view, the method disclosed by the invention has an important significance for revealing an internal mechanism for controlling the size of an osmotic coefficient of the soil, analyzing seepage of unsaturated soil and researching hydromechanical coupling.

Owner:HUBEI UNIV OF TECH

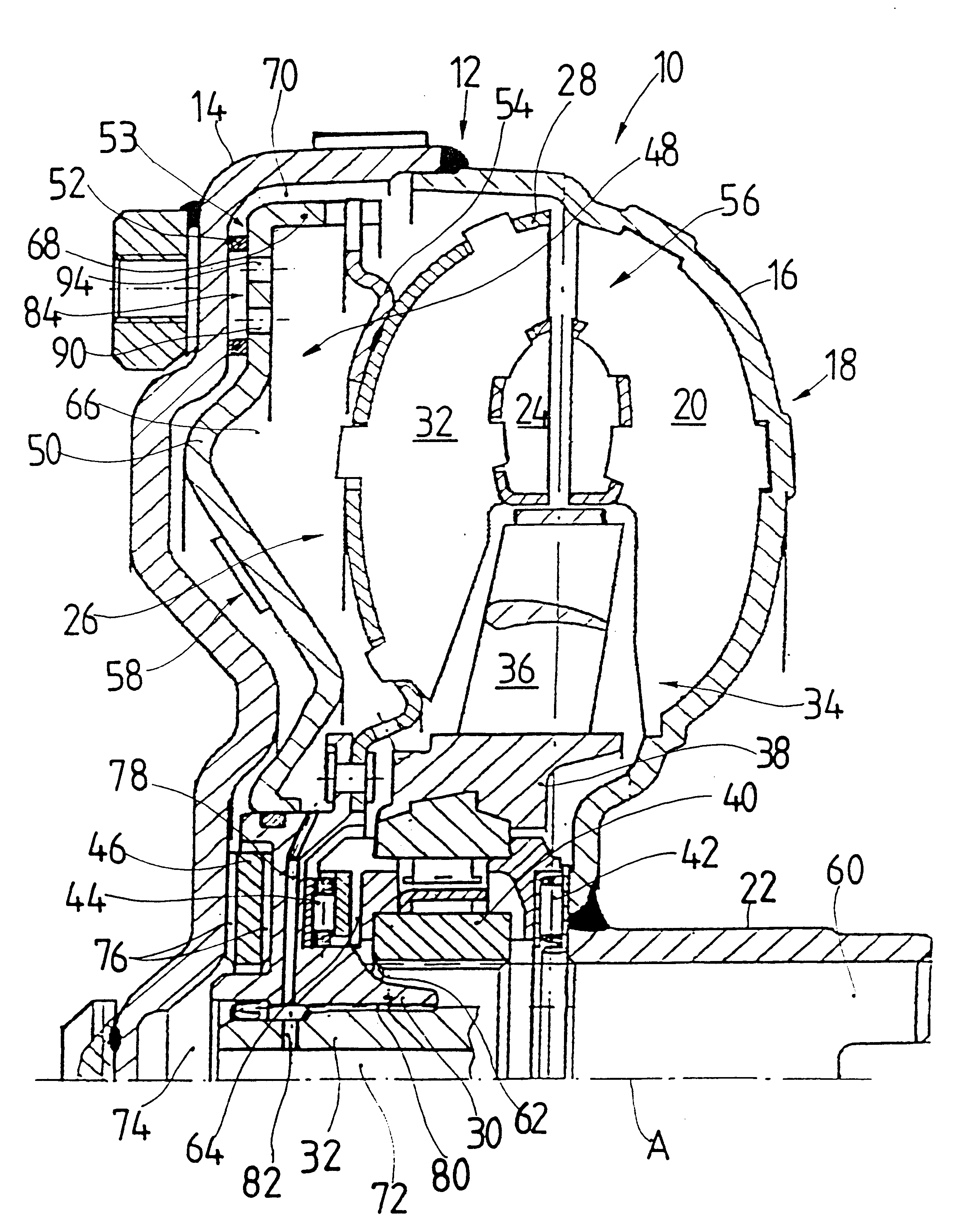

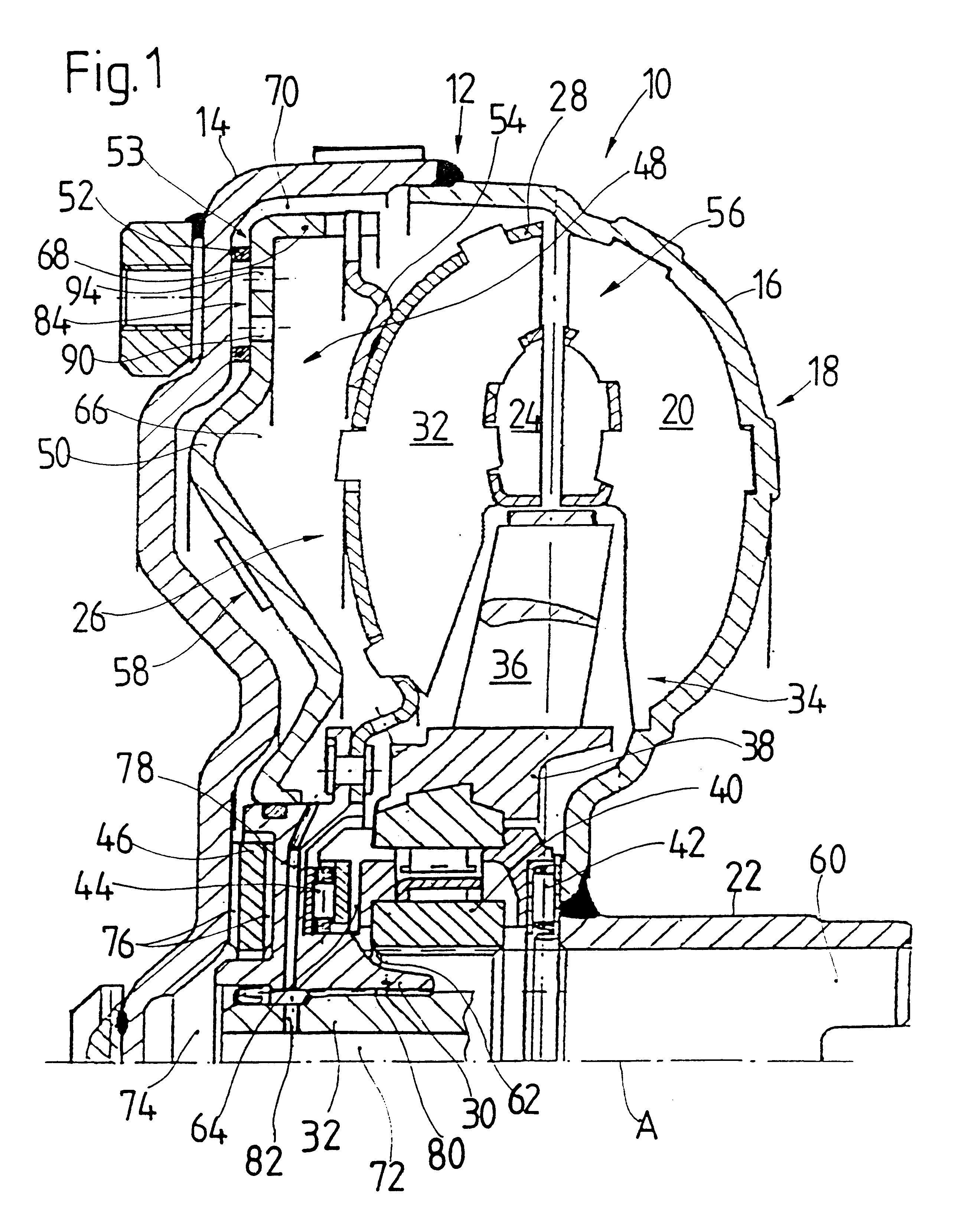

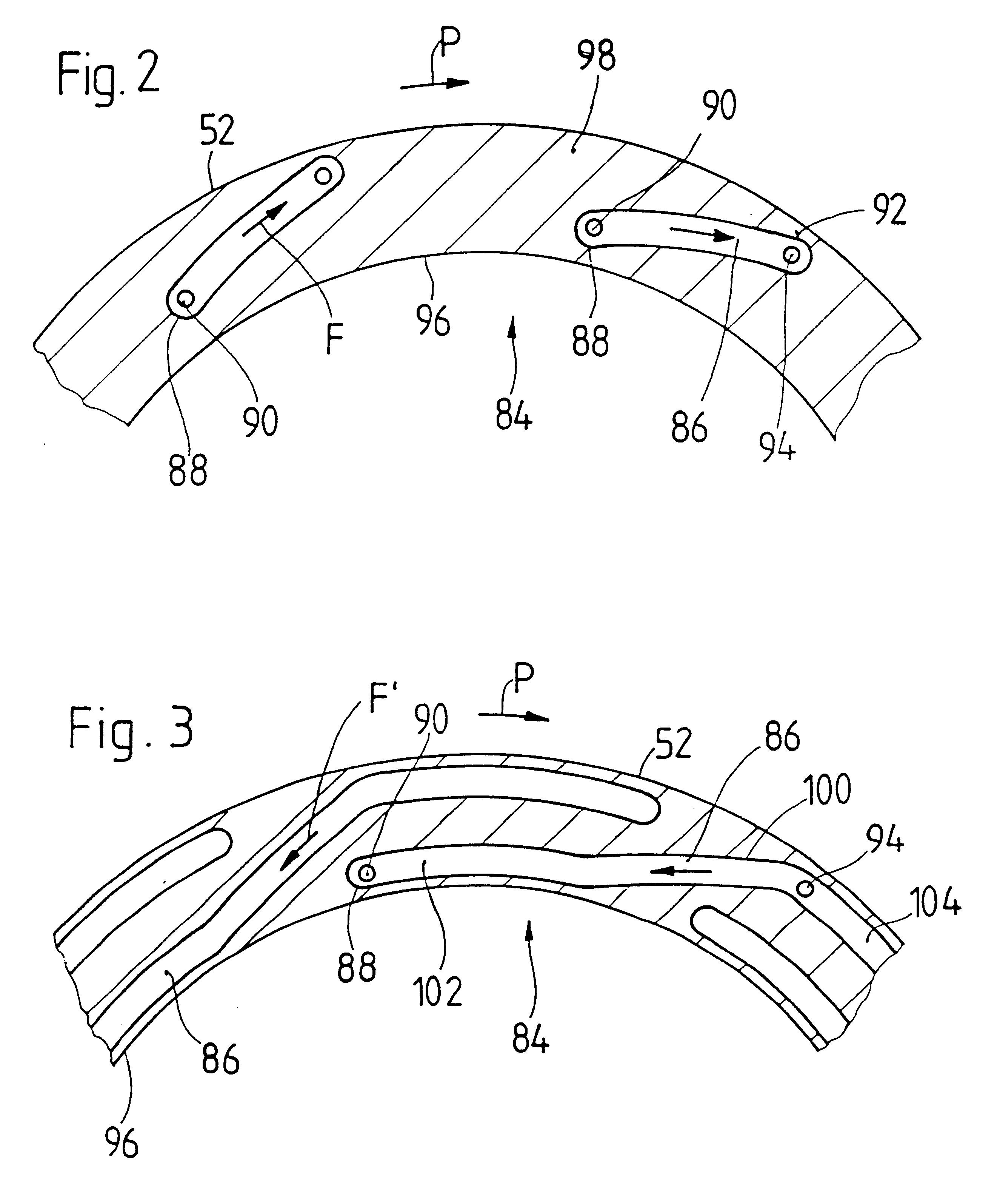

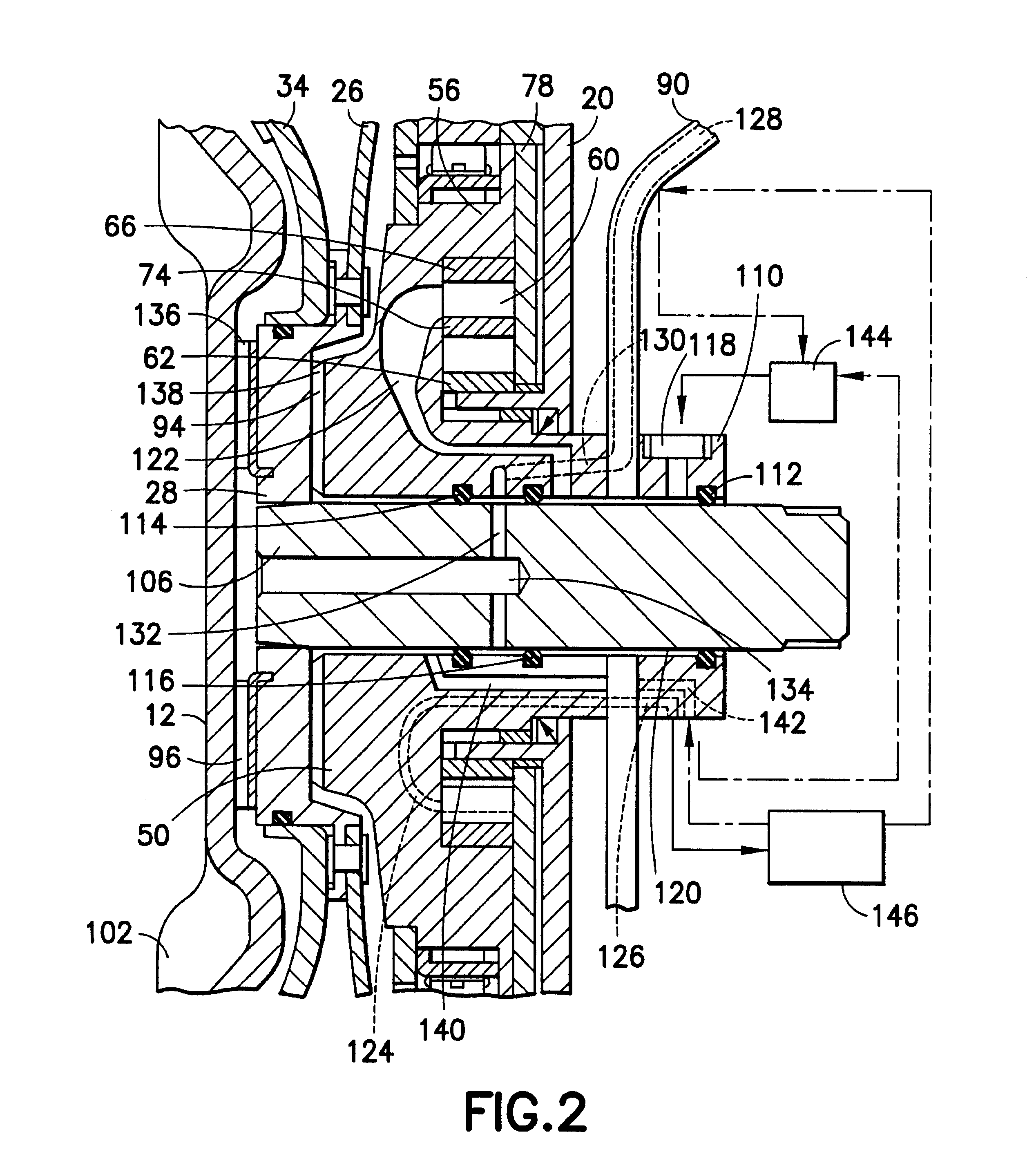

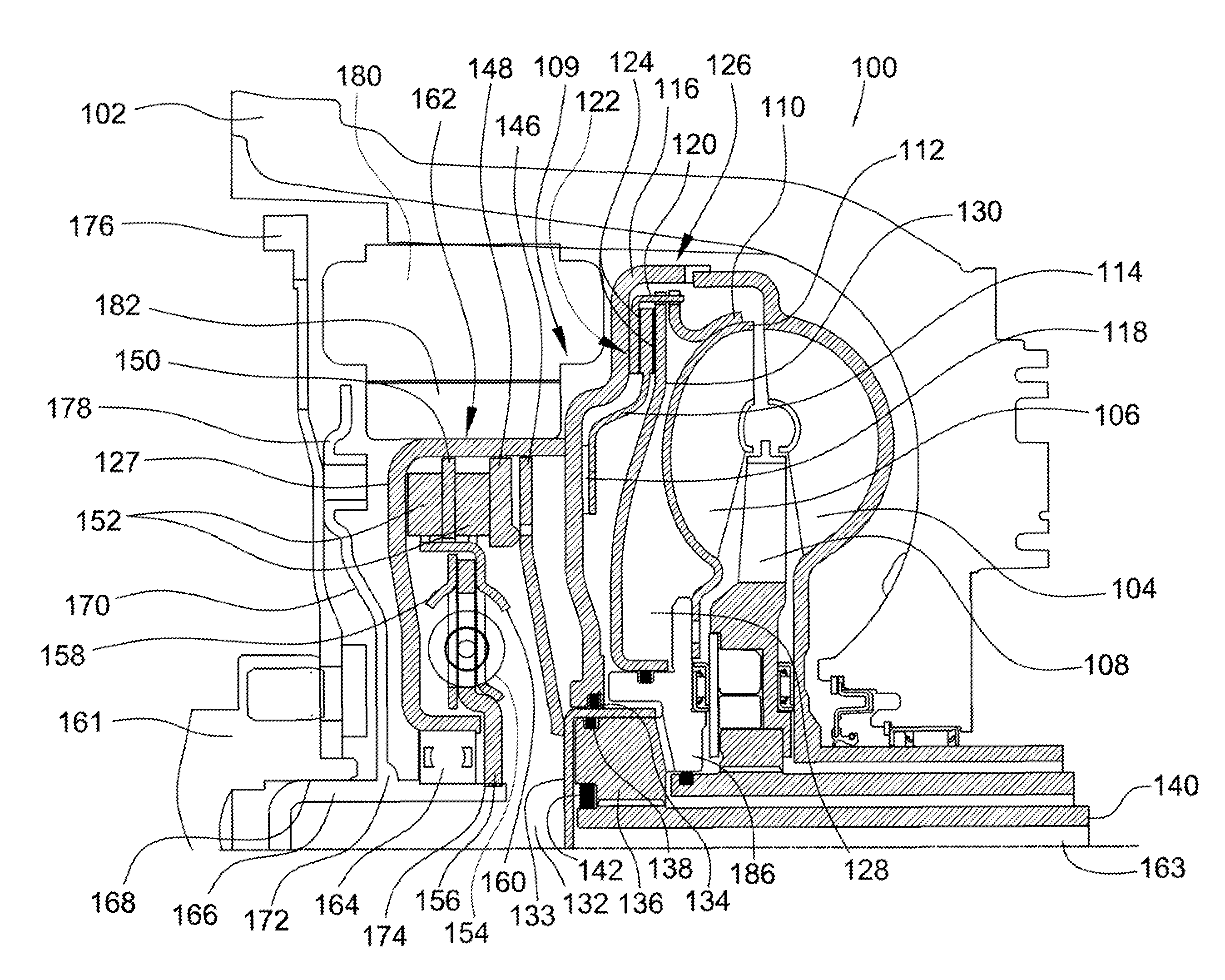

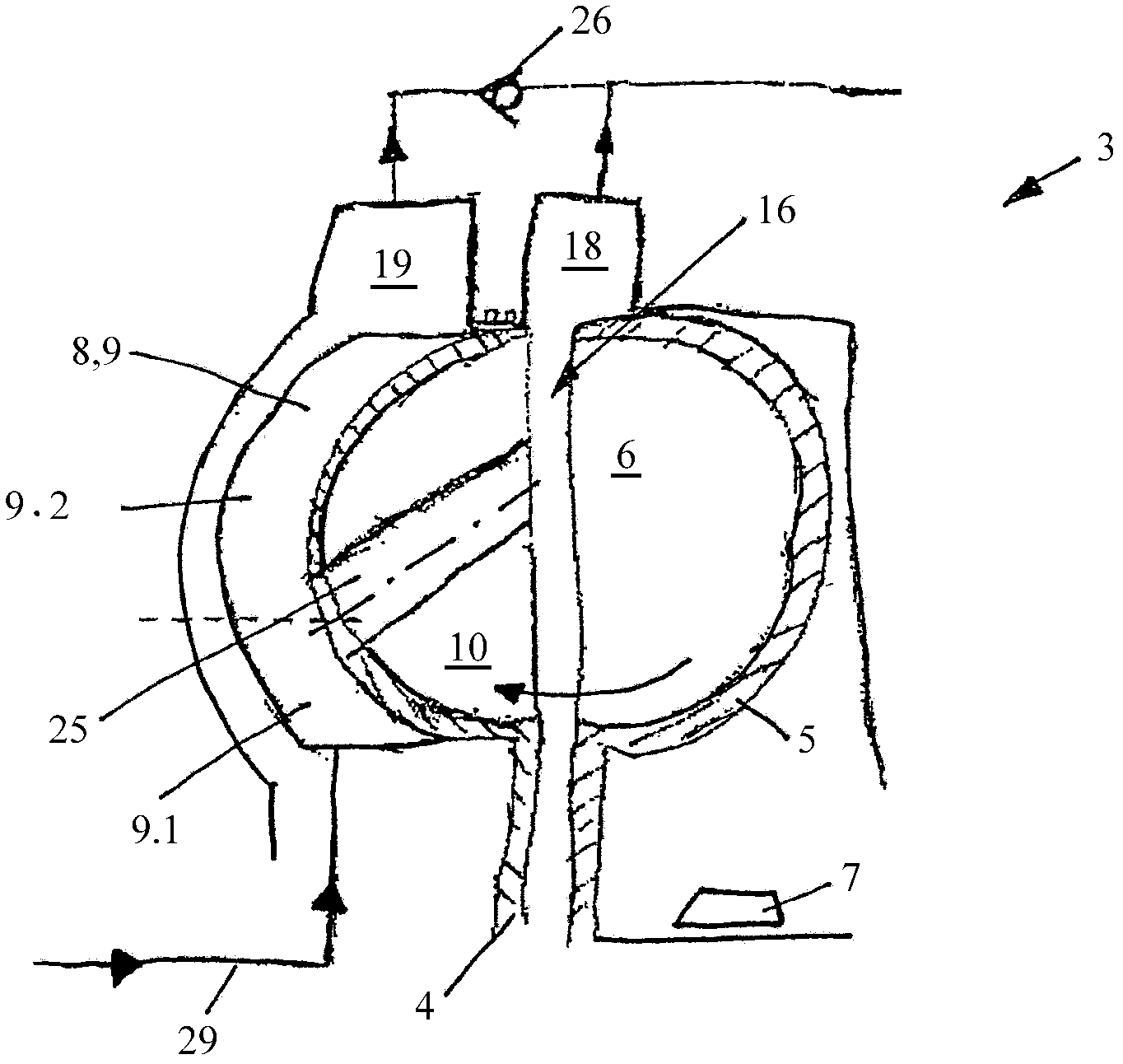

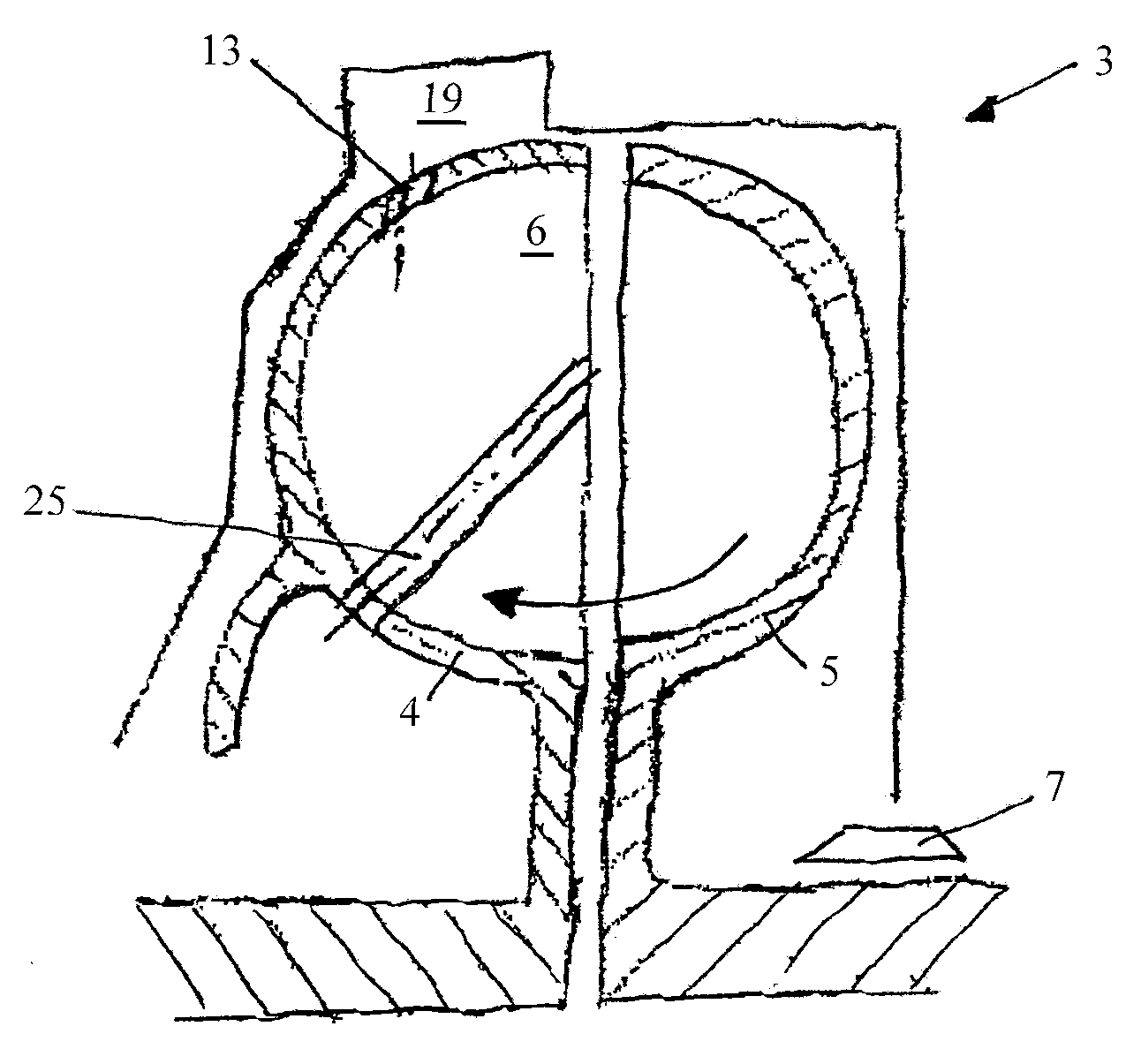

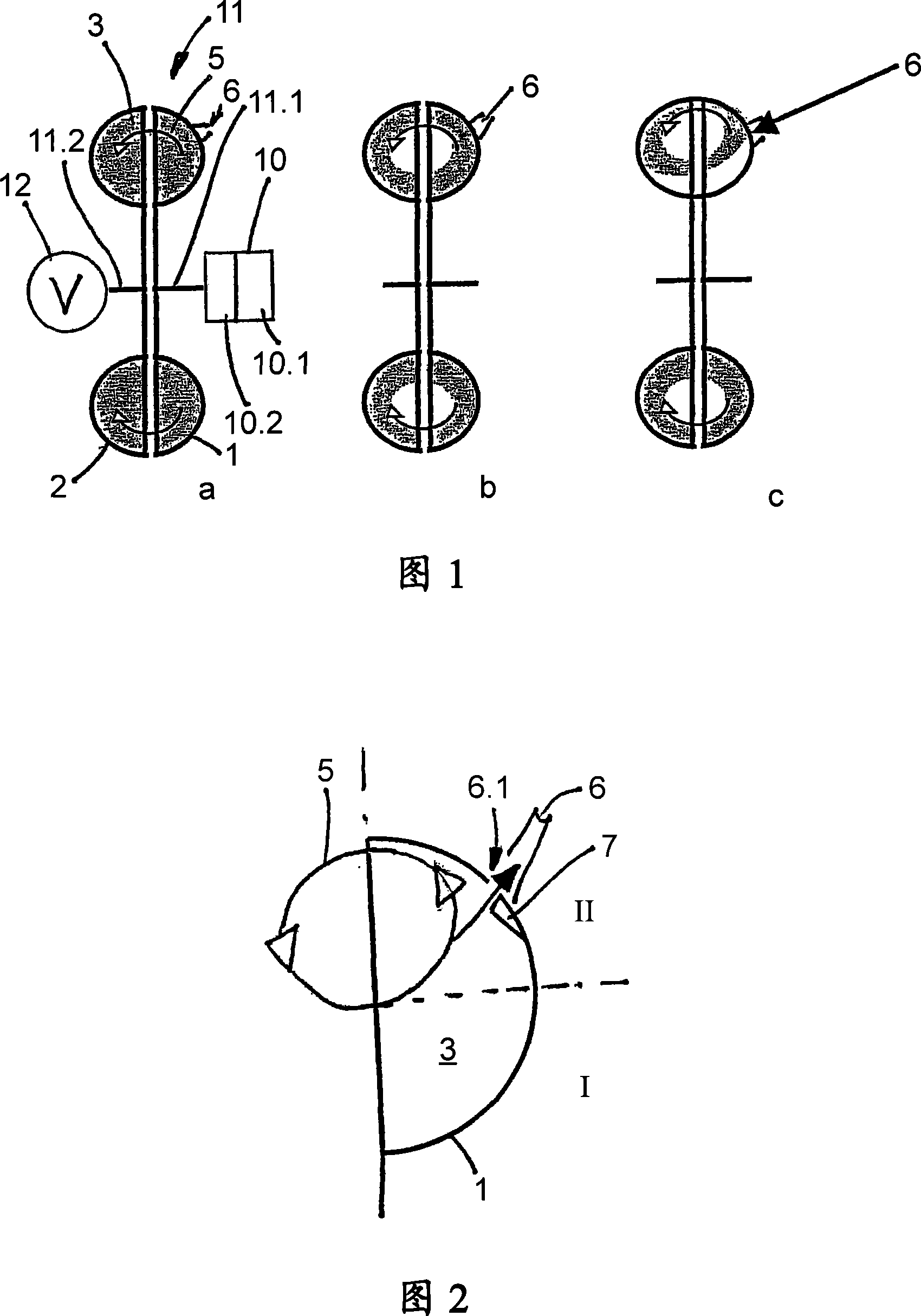

Hydrodynamic coupling device

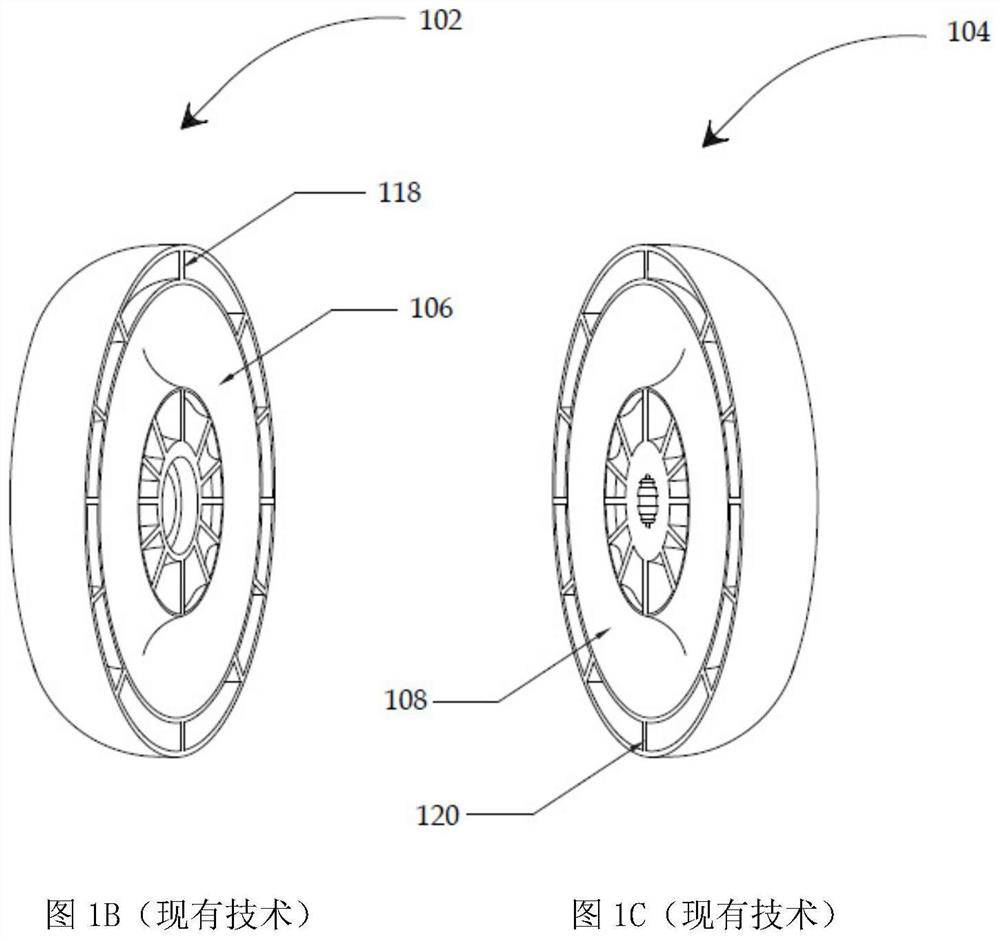

InactiveUS6497312B1Reduce drag torqueReduce componentsRotary clutchesFriction clutchesWorking fluidCoupling

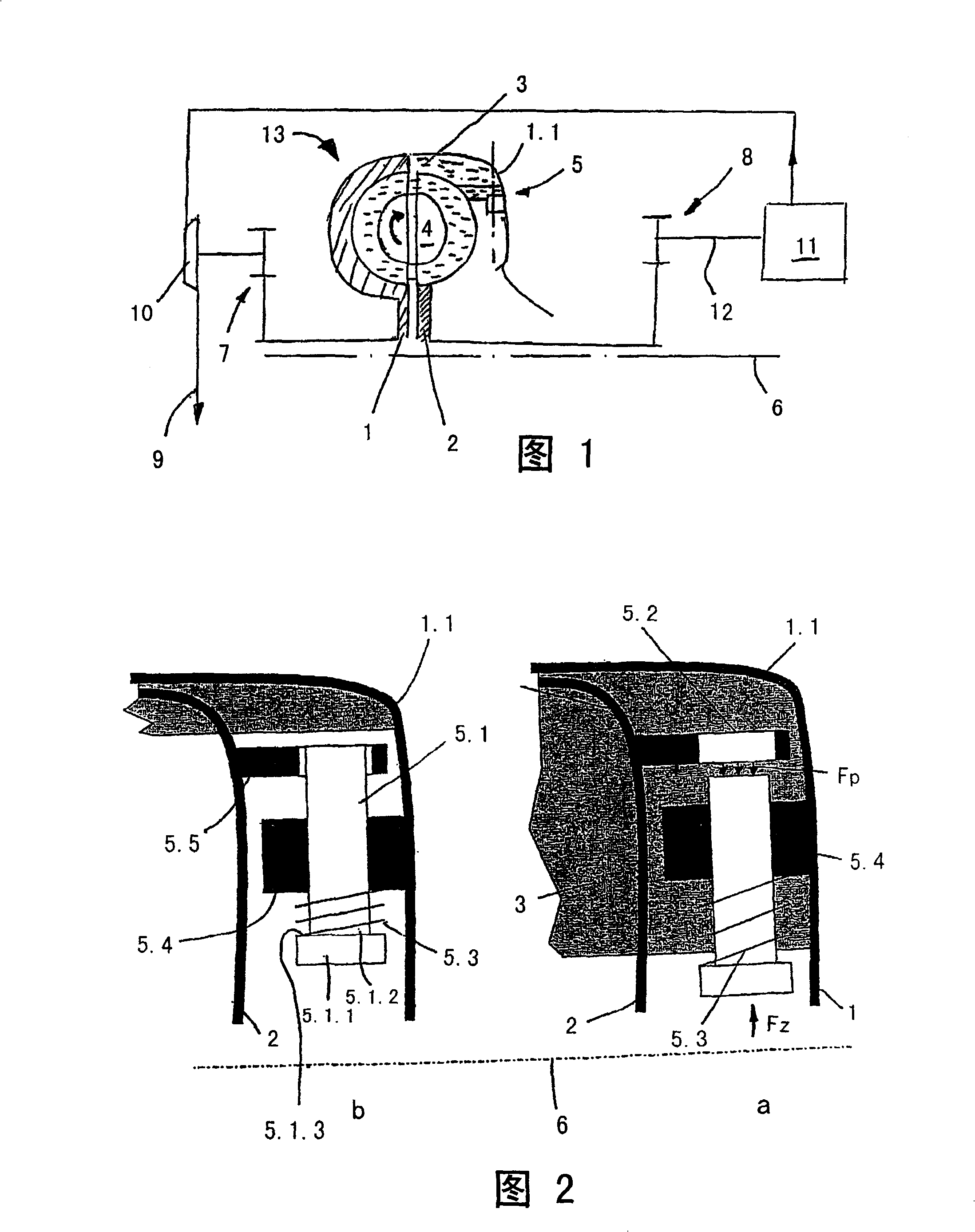

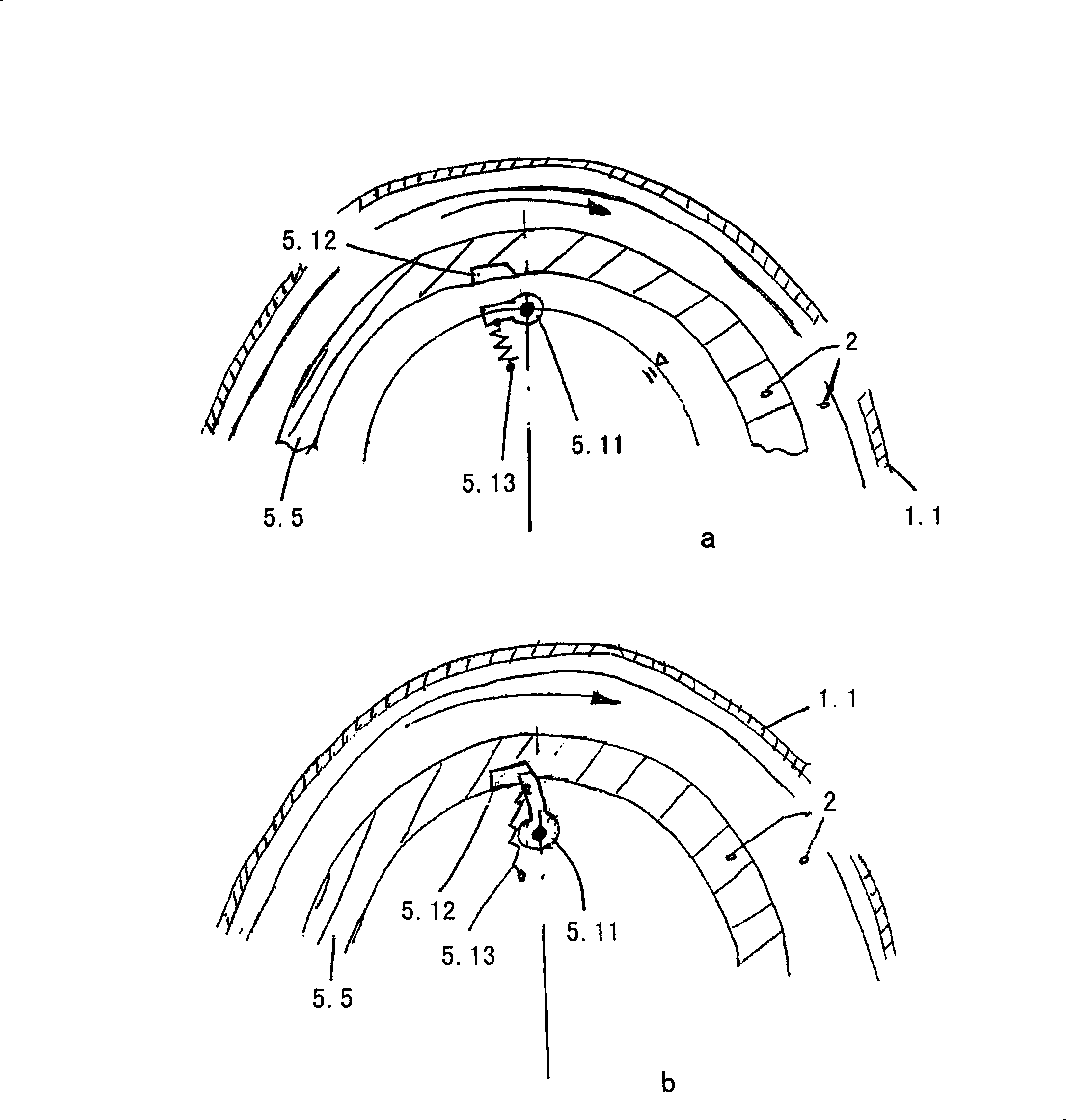

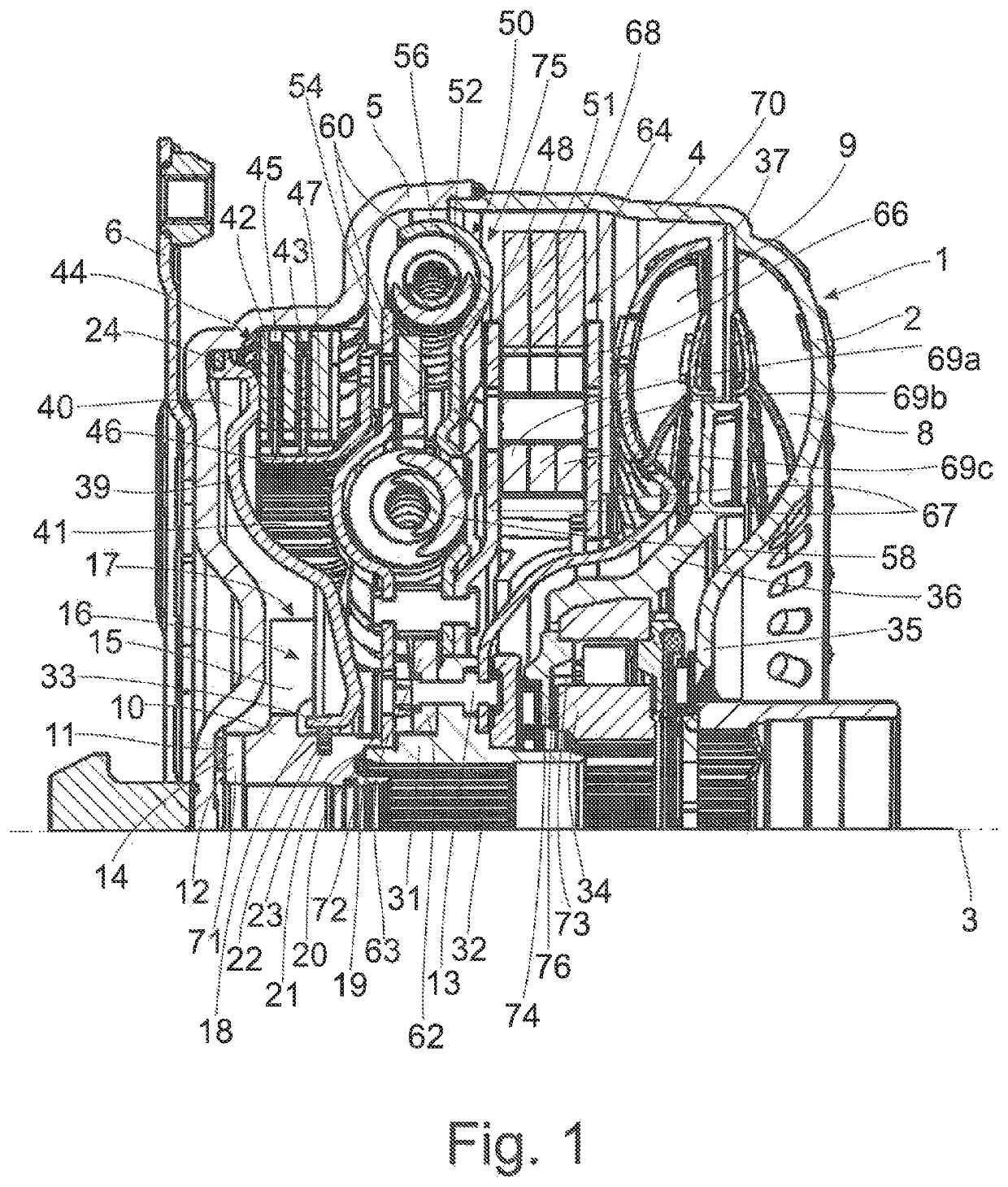

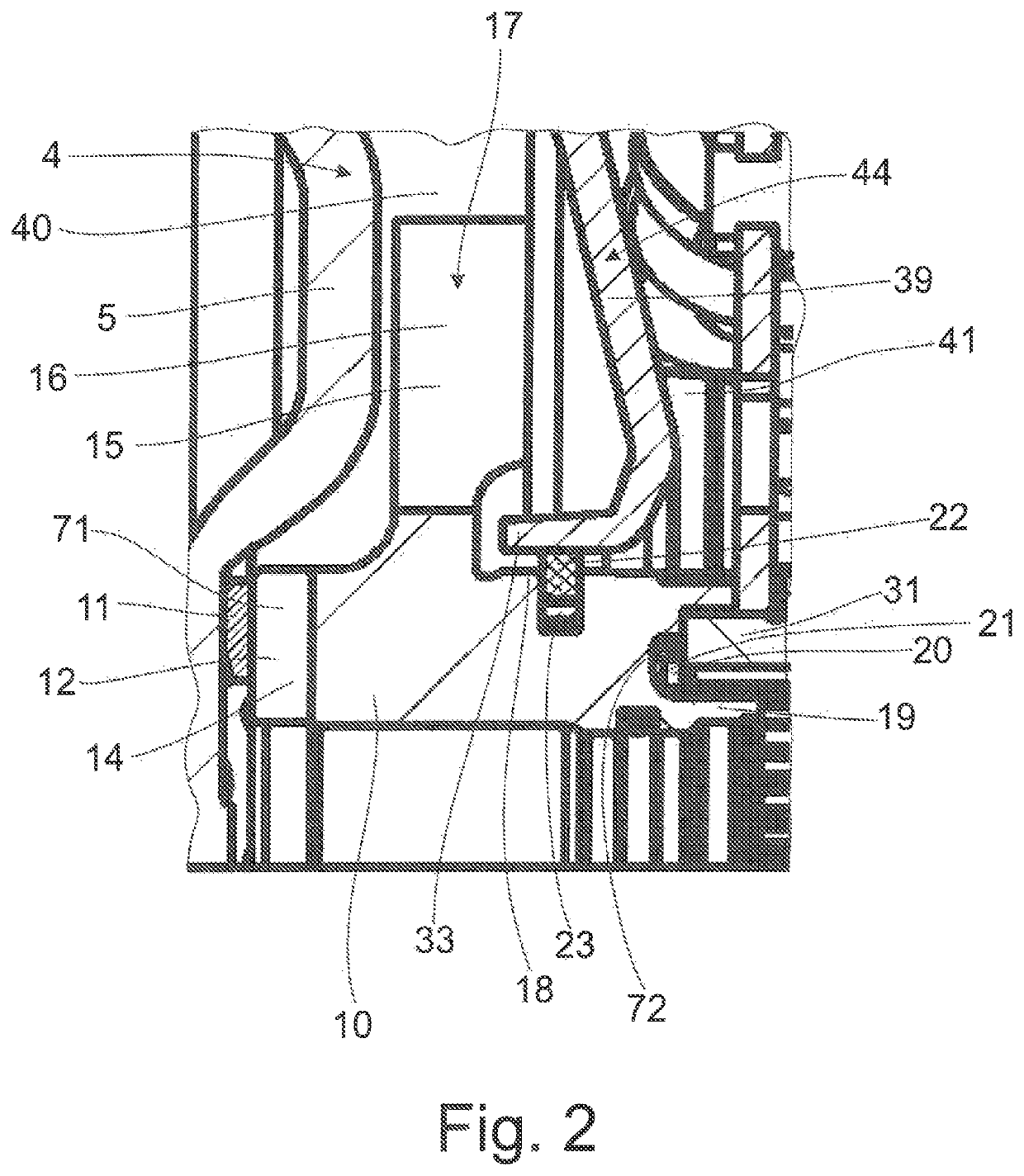

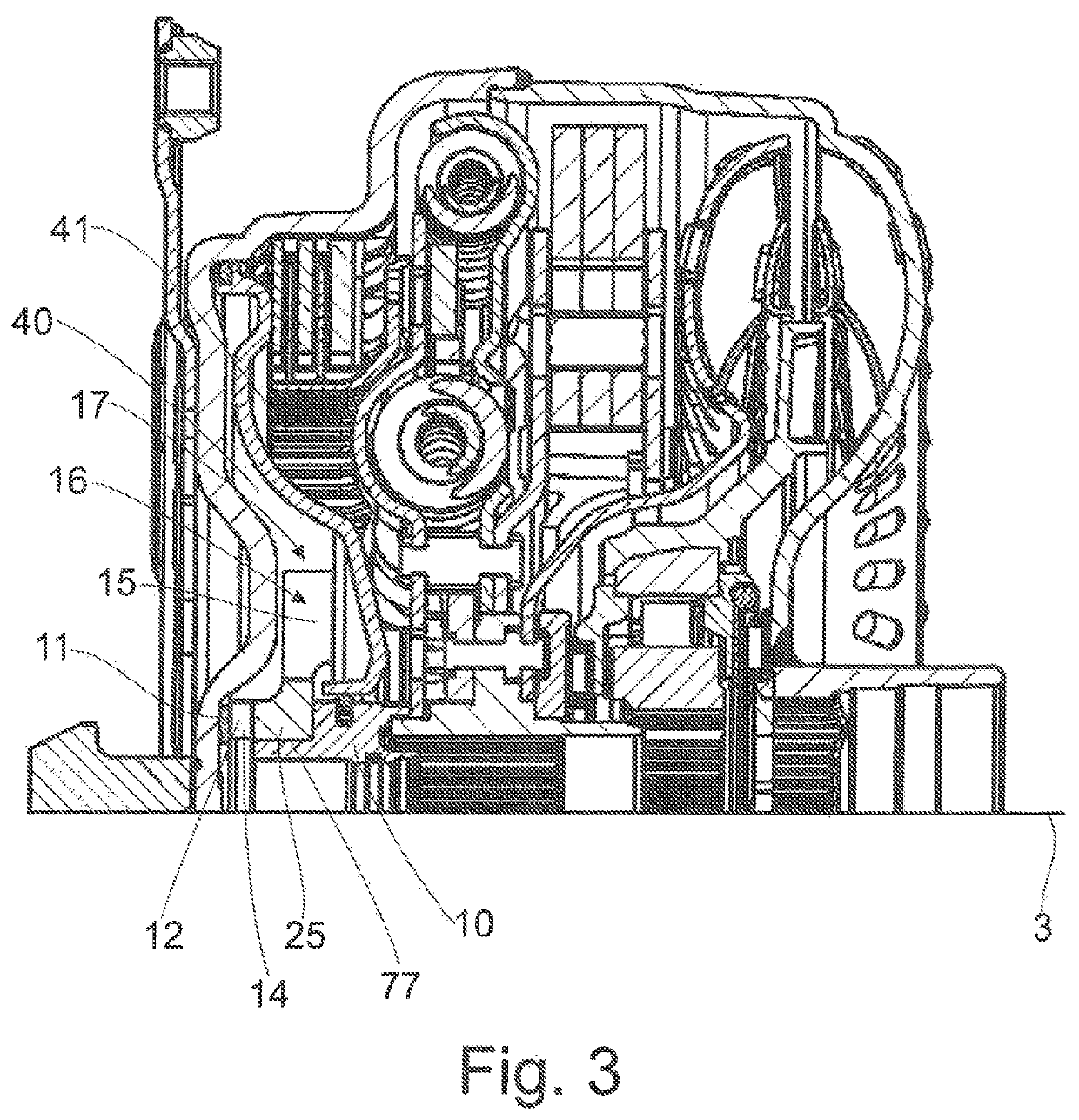

A hydrodynamic coupling device is provided including a housing, a lock up clutch, a friction surface mechanism, a fluid duct and three connecting ducts. The lock up clutch has a clutch element arranged in the housing and may be pressed against the housing. The friction surface mechanism is arranged between the clutch element and the housing. The clutch element and the friction surface mechanism separate an interior of the hydrodynamic coupling device into a first fluid space and a second fluid space. The fluid duct means is in the friction surface mechanism and permits the working fluid to flow into and out of the first fluid space while preventing the working fluid from flowing out of the first fluid space into the second fluid space. The connecting ducts are in the fluid duct, with the first connecting duct is capable of permitting flow of the working fluid to the first fluid space, the second connecting duct is capable of permitting flow of the working fluid into and out of the second fluid space. The third connecting duct is capable of circulating the working fluid within the first fluid space before permitting the working fluid to flow out of the first fluid space, at least when the clutch element is pressed up to the housing with the friction surface arrangement interposed between them.

Owner:ZF FRIEDRICHSHAFEN AG

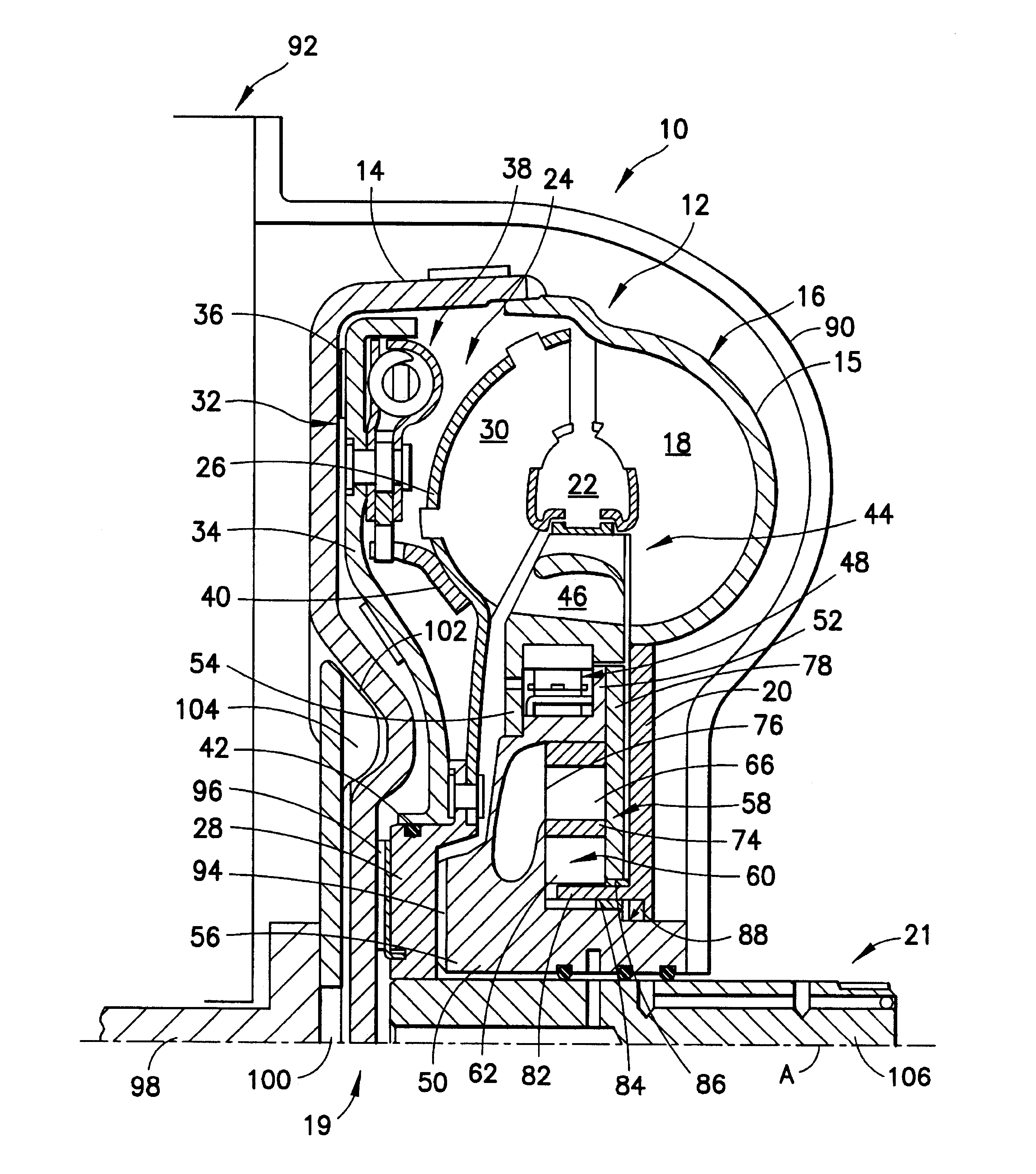

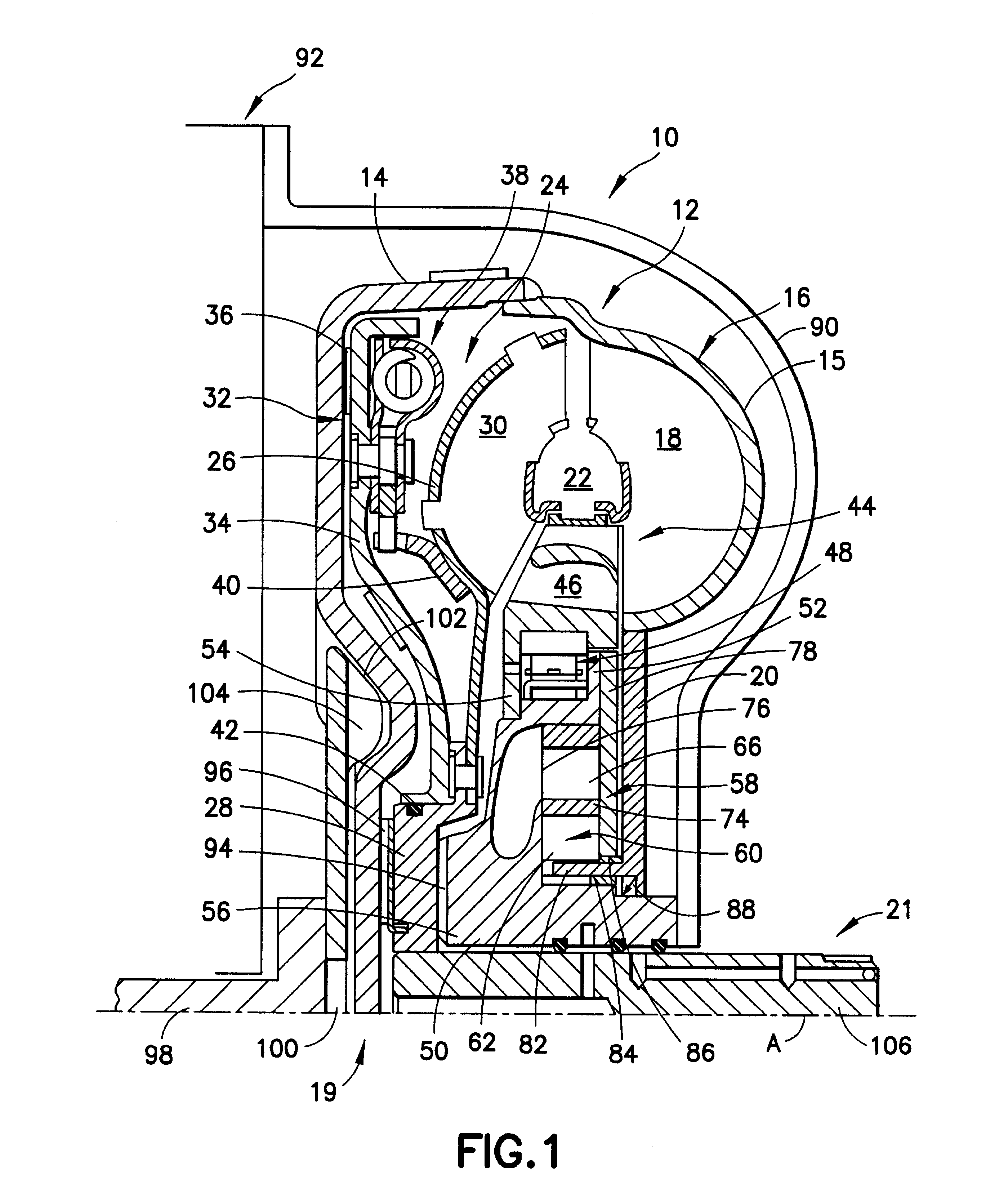

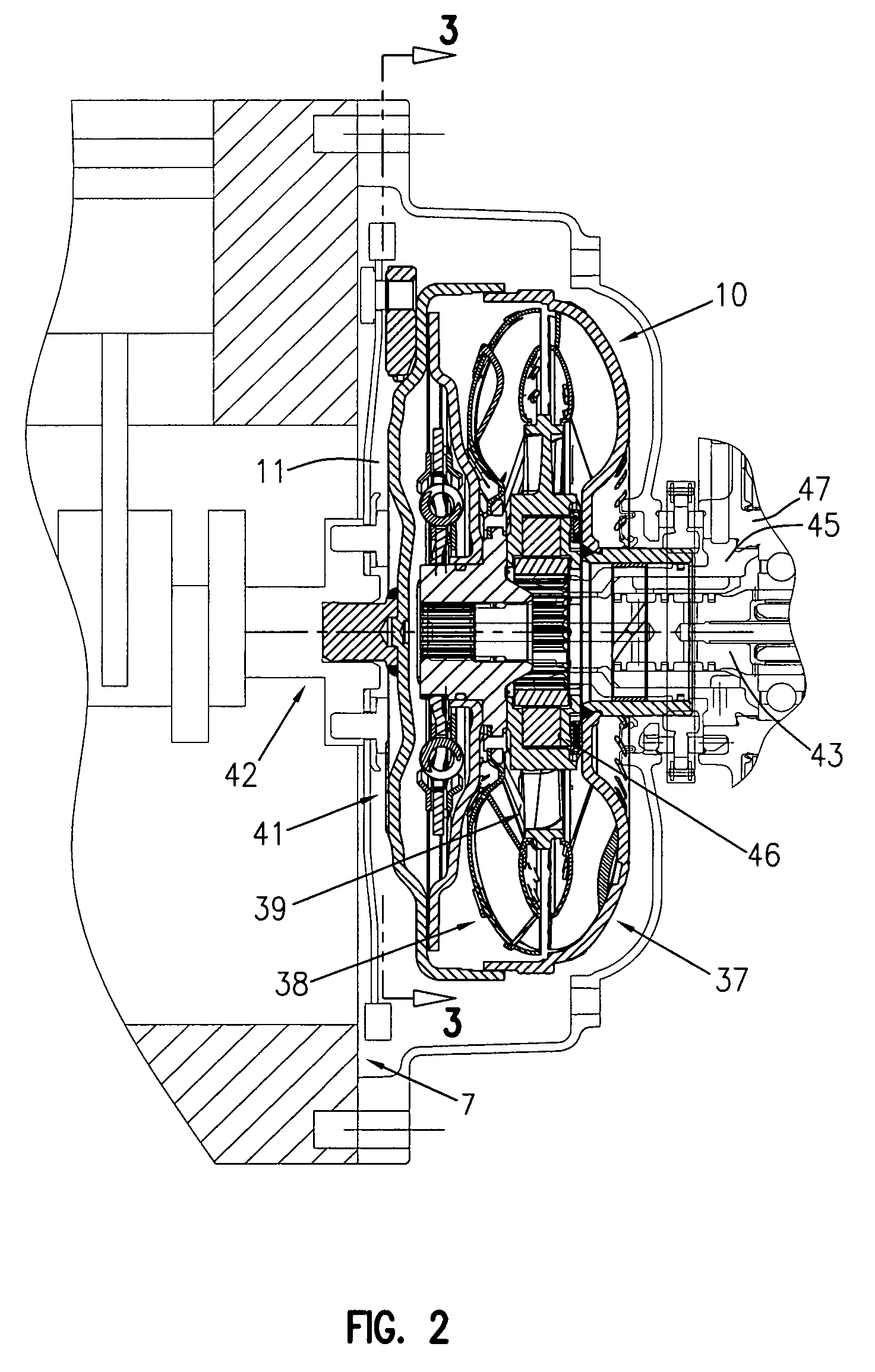

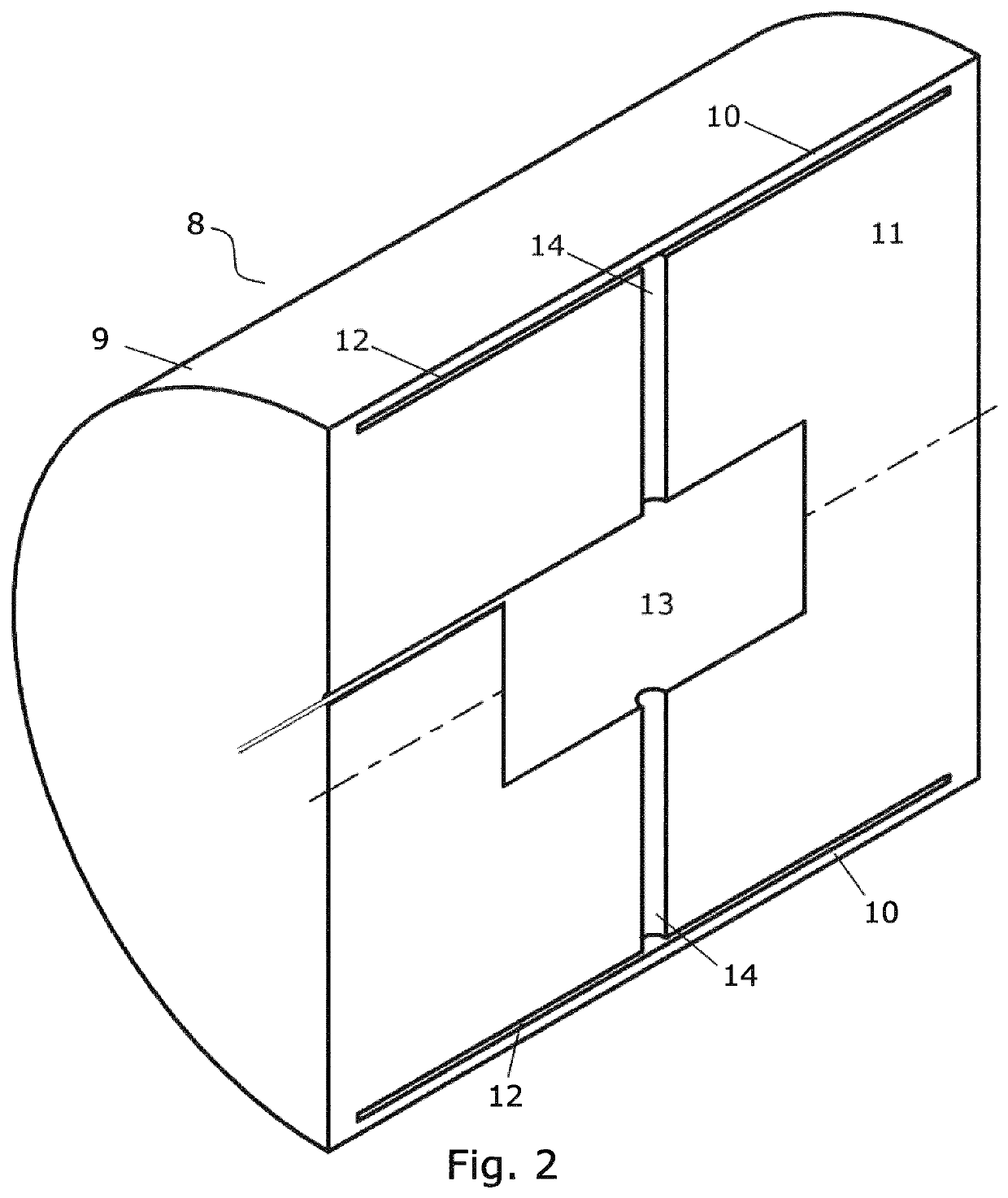

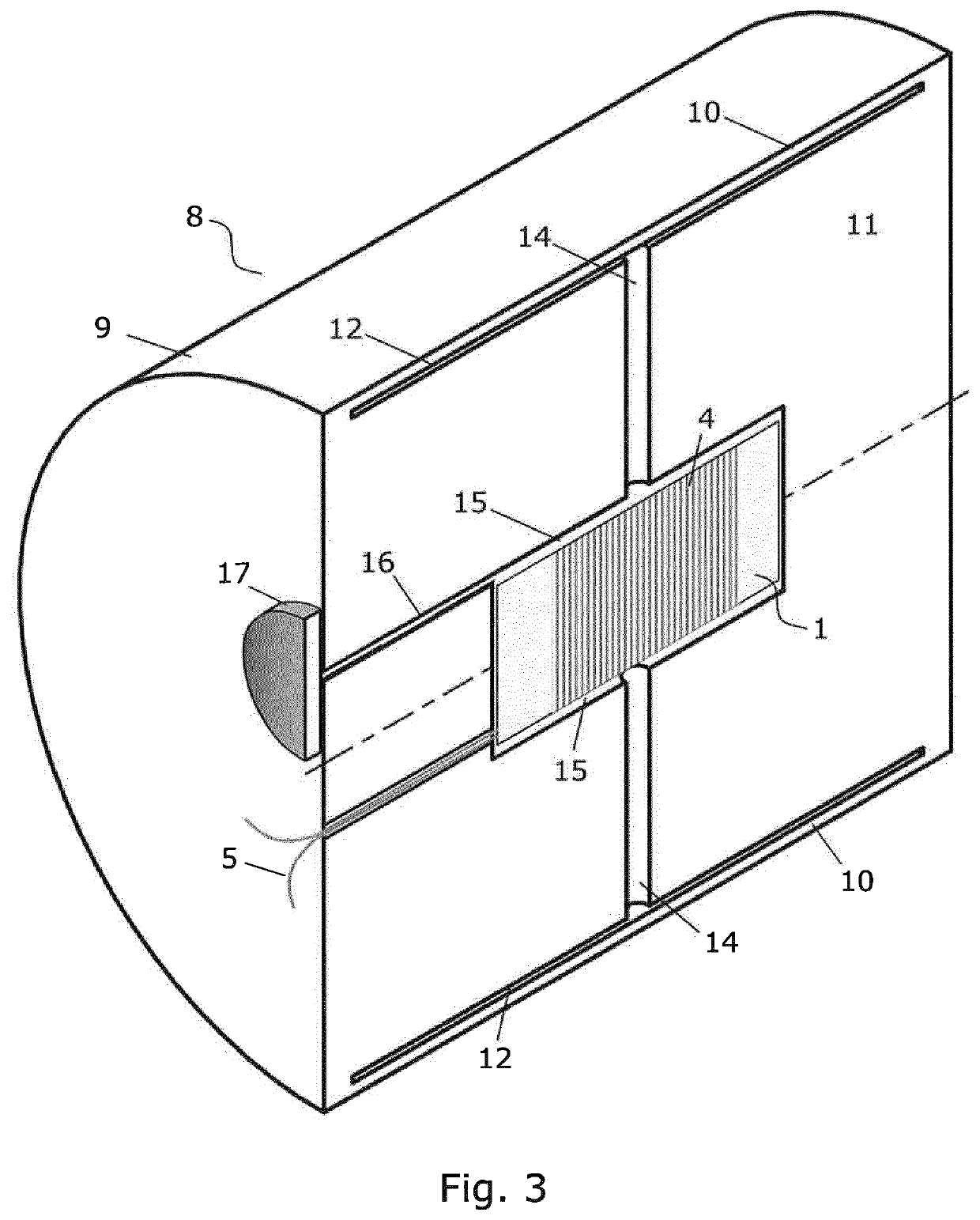

Hydrodynamic coupling device

InactiveUS6564914B1Easy to assembleSimple designRotary clutchesAssembly machinesBrake torqueCoupling

A hydrodynamic coupling device for producing a torque transmission connection between a drive unit and a transmission is provided including a first coupling device attached to the drive unit for coupling the hydrodynamic coupling device with the drive unit for transmitting a torque between the hydrodynamic coupling device and the drive unit and a second coupling device attached to the transmission for coupling the hydrodynamic coupling device with the transmission for transmitting a driving and / or braking torque between the hydrodynamic coupling device and the transmission. A method of making a hydrodynamic coupling device is also provided.

Owner:MANNESMANN SACHS AG

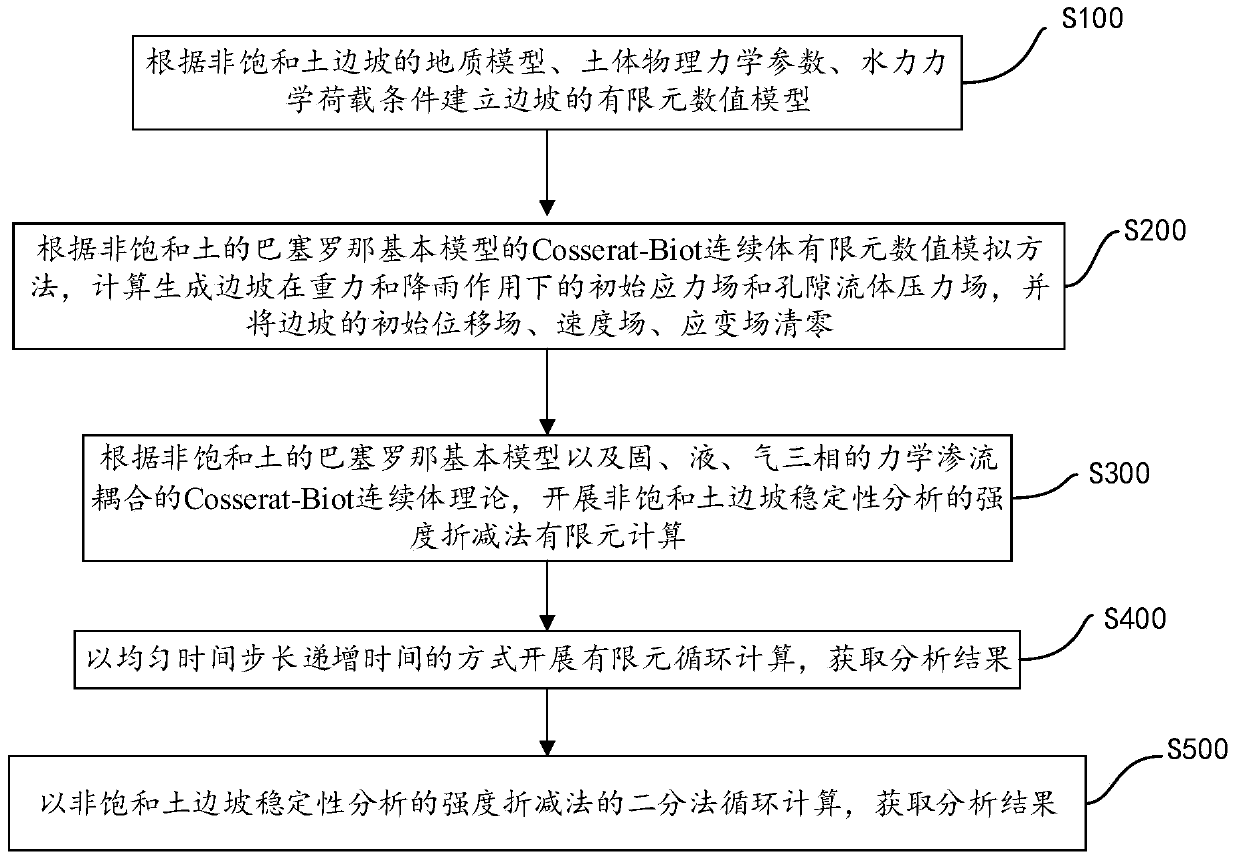

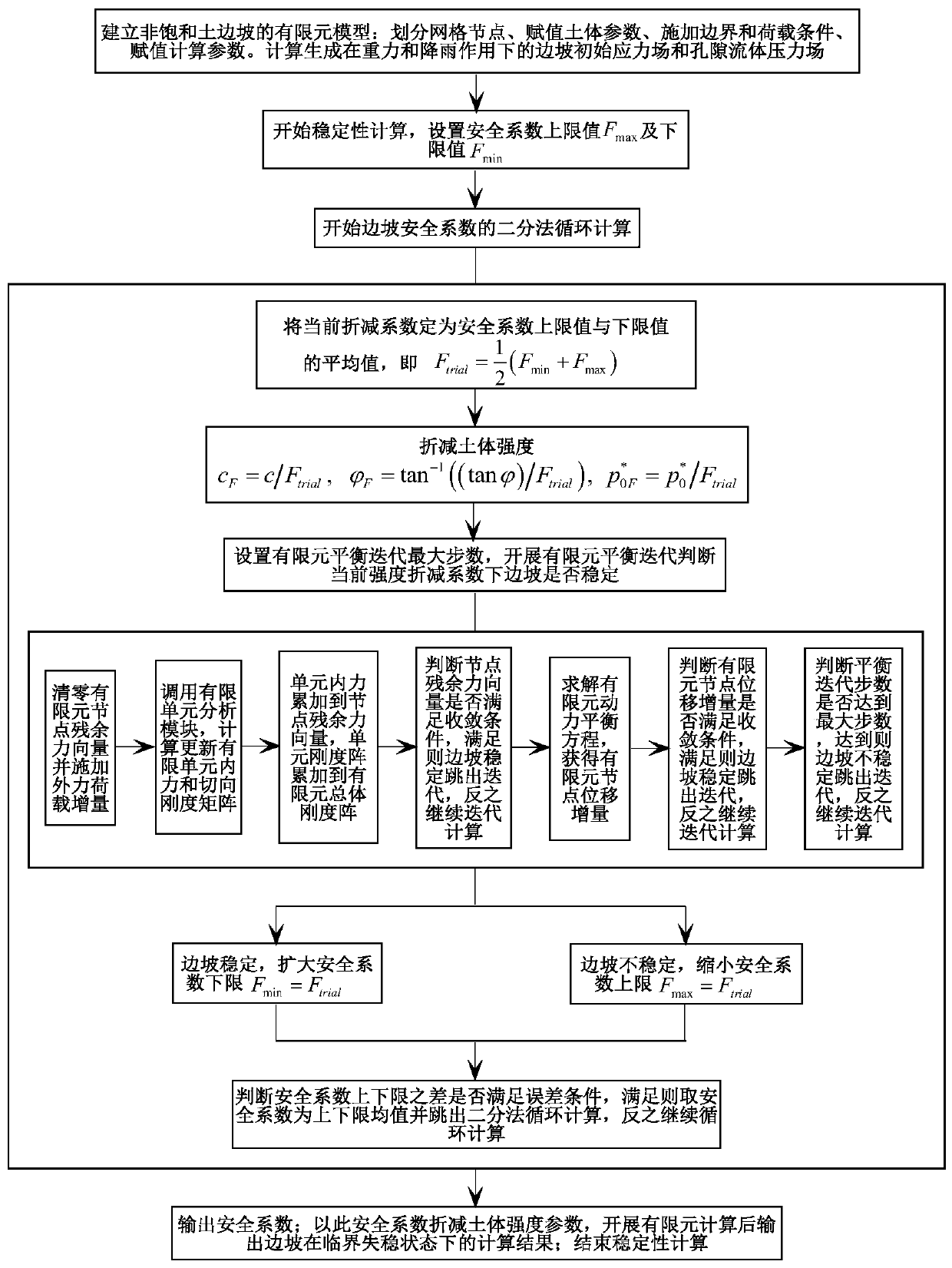

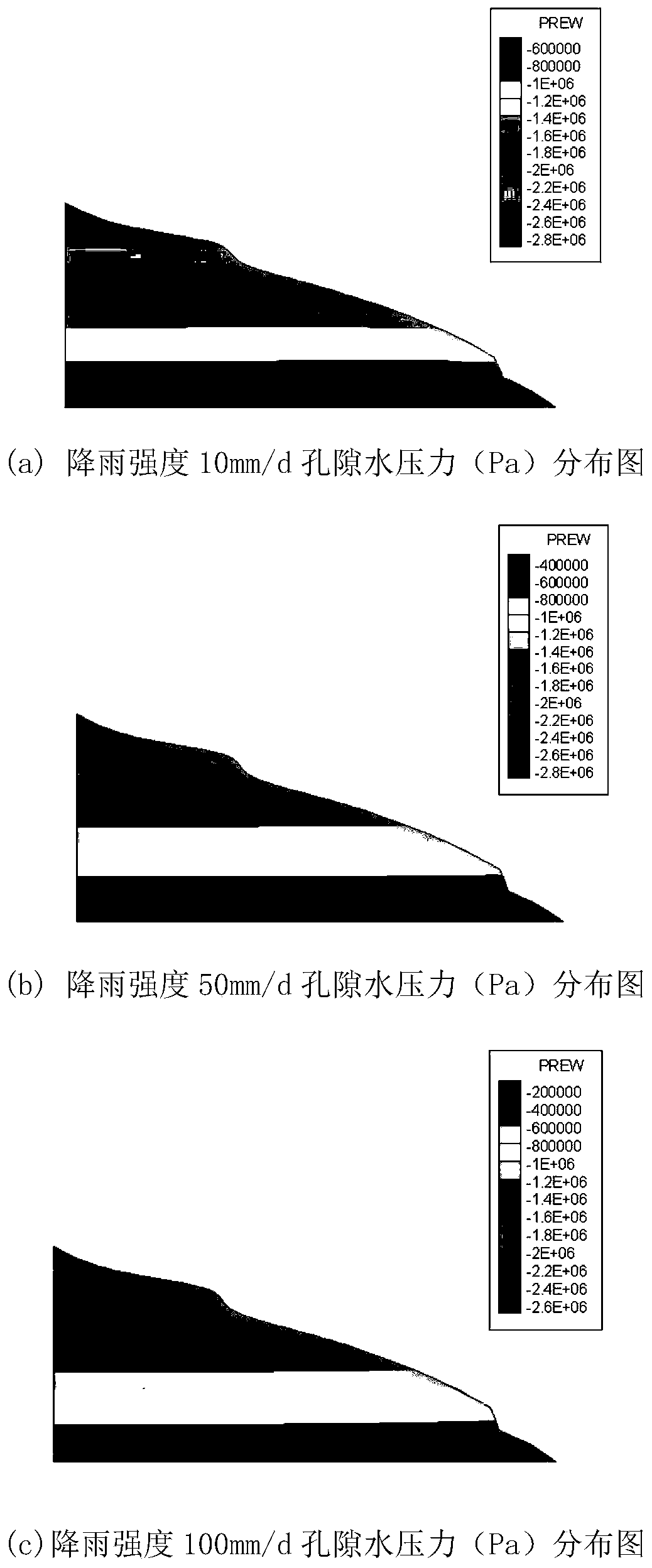

Stability analysis method for hydromechanical coupling of unsaturated soil slope

ActiveCN110598273AImprove accuracySpecial data processing applicationsIn situ soil foundationSuction forceSoil science

The invention provides a stability analysis method for hydromechanical coupling of an unsaturated soil slope, and belongs to the technical field of rock and soil. According to the stability analysis method, a Barcelona basic model more conforming to the property of the unsaturated soil is adopted for a constitutive model of the unsaturated soil, and the influence of suction force and the influenceof shear strength and compressive strength of a soil body are considered in the constitutive model. According to the strength reduction method for unsaturated soil slope stability analysis, the shearstrength of a soil body is reduced by reducing the cohesive force and the friction angle of the soil body. In addition, the reduction of the compressive strength of the soil body is taken into account by reducing the consolidation pressure in front of the soil body. The stability analysis of the unsaturated soil slope is carried out under the Cosserat continuum frame, and the influence of the microstructure effect of the soil body on the stability of the macroscopic slope is considered to a certain extent. According to the stability analysis method, various influence factors are considered, and the stability analysis accuracy of the unsaturated soil slope is improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY +1

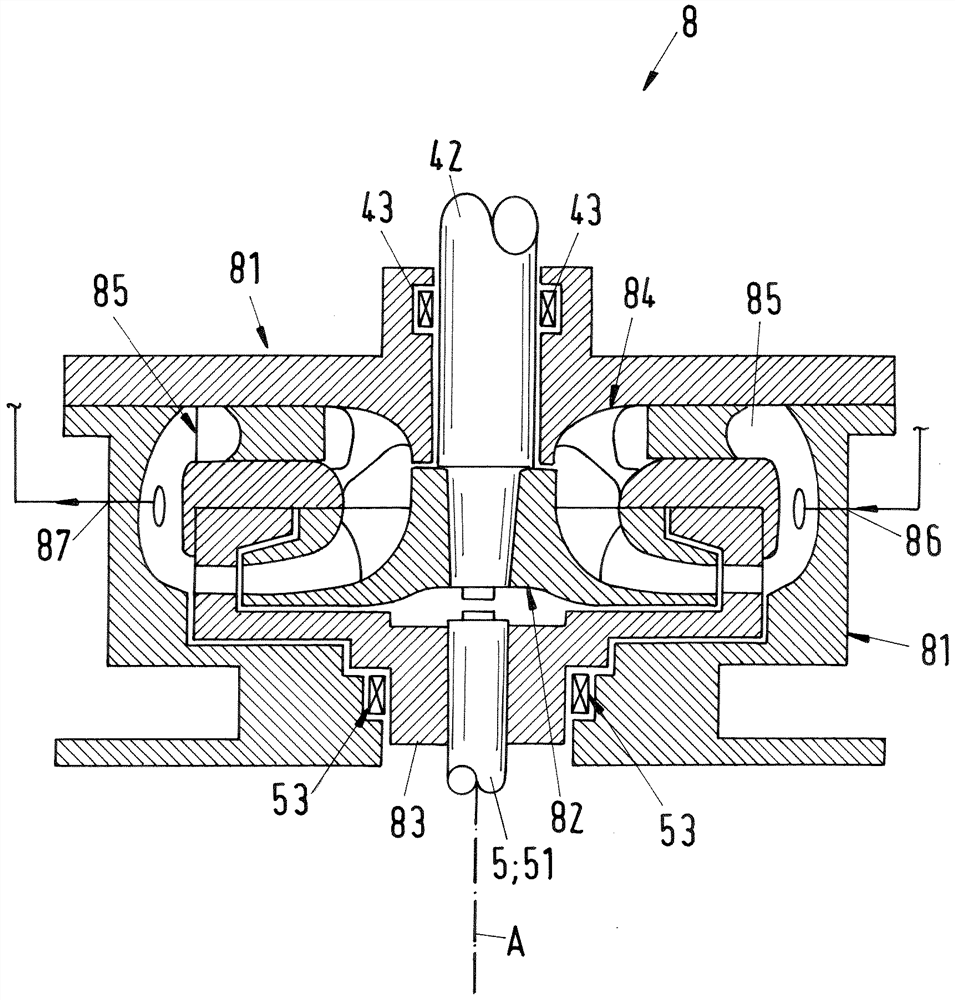

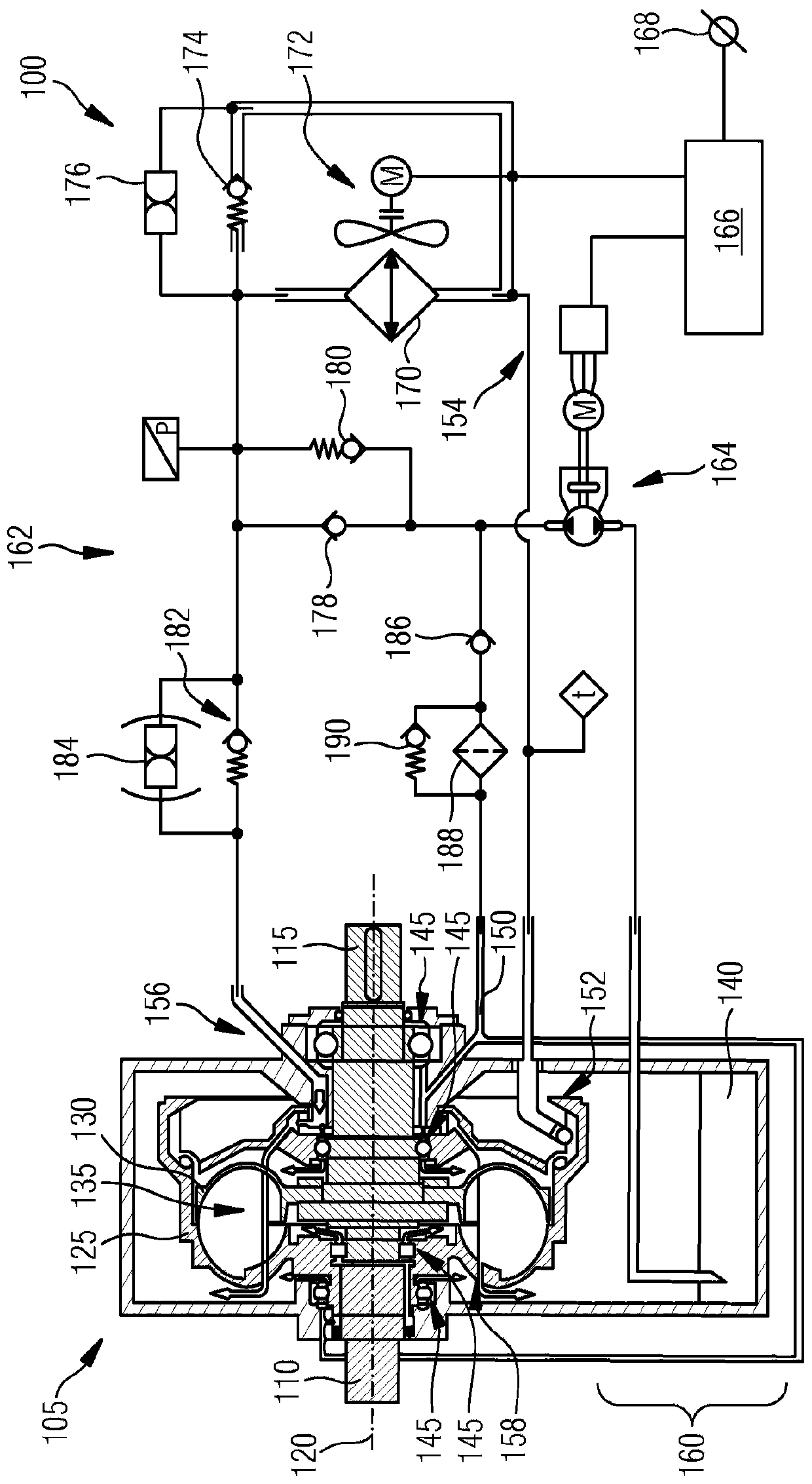

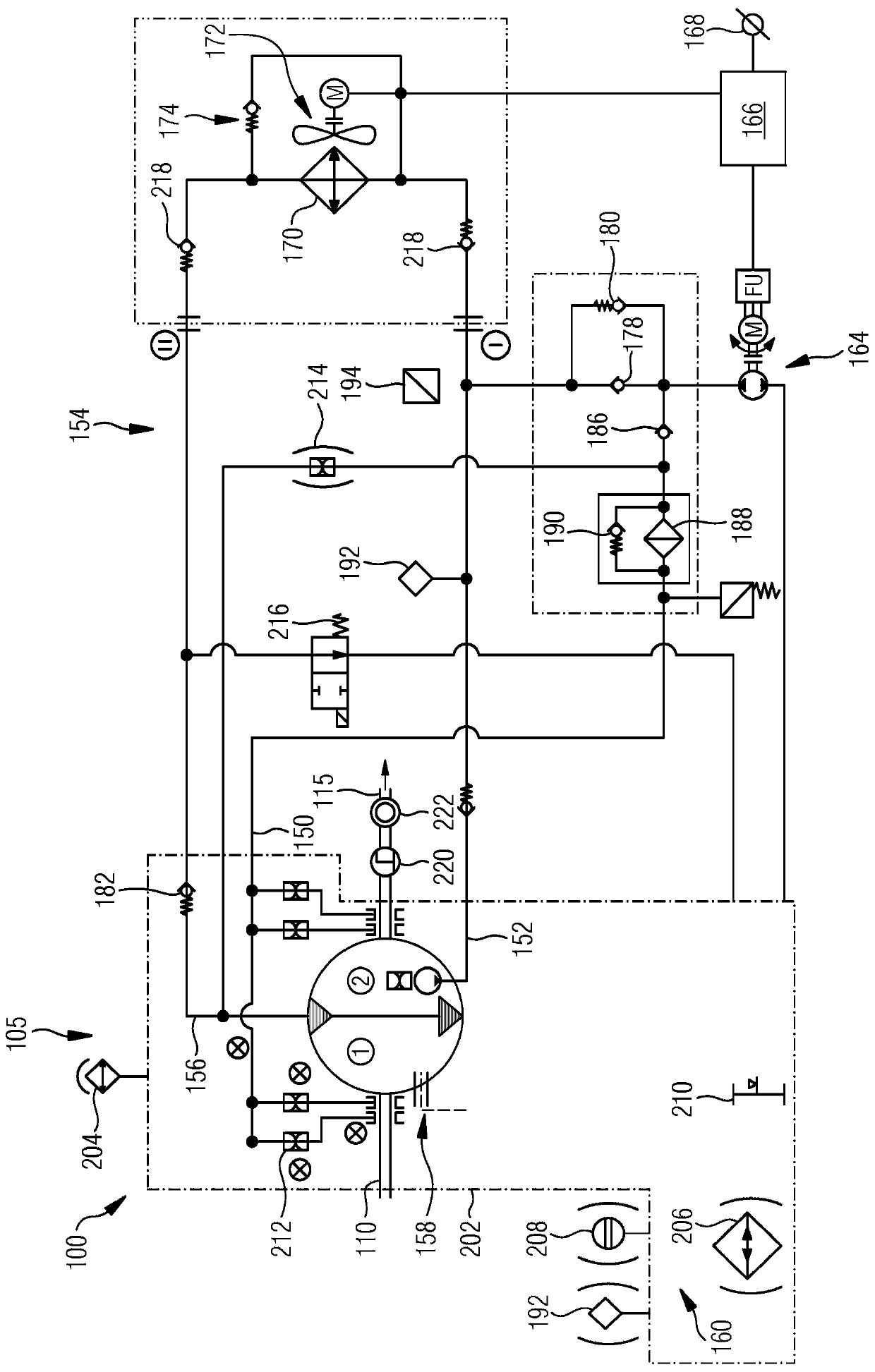

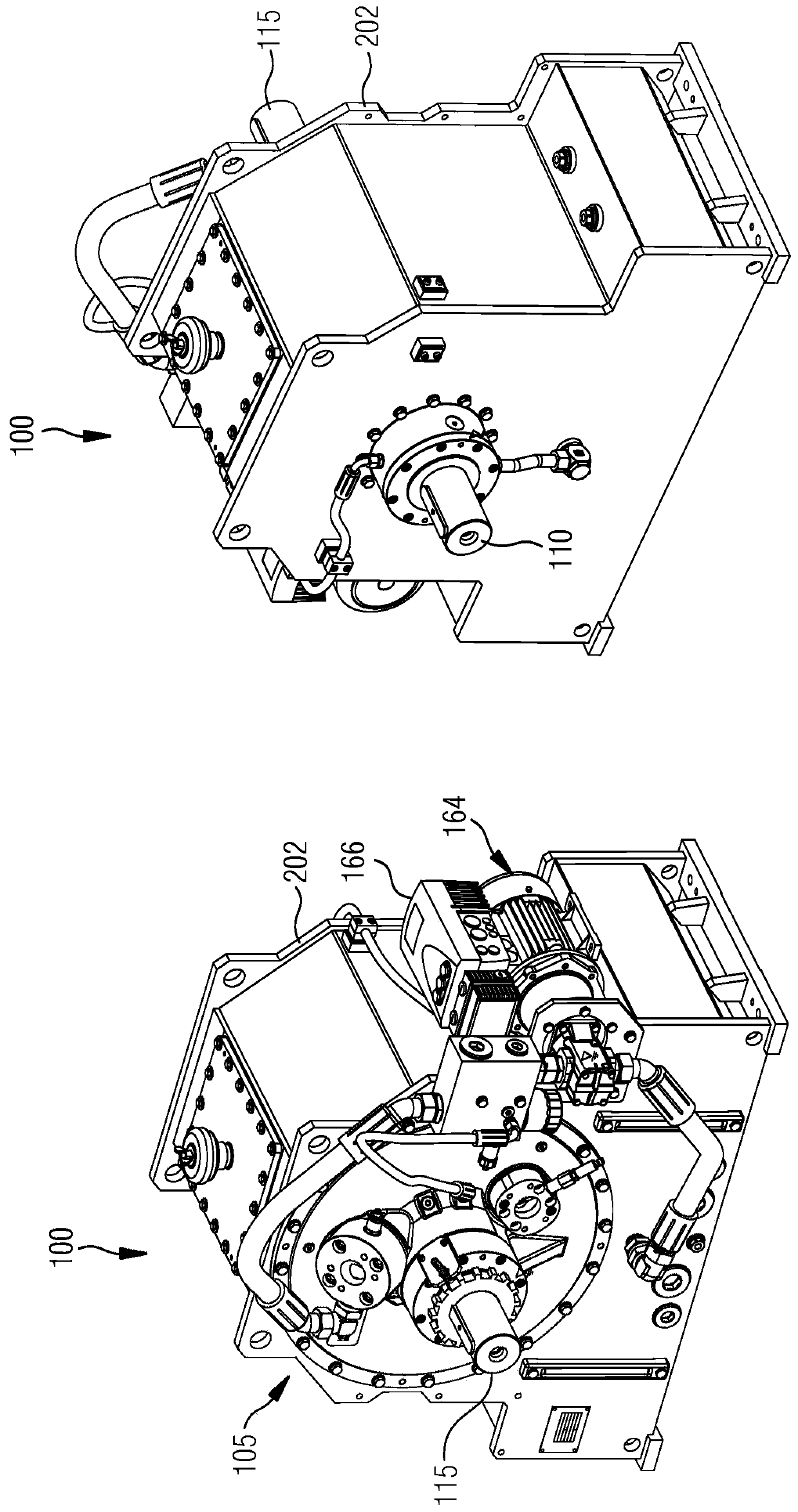

Hydrodynamic coupling device for hybrid vehicles

ActiveUS8240441B2Reduce complexityMechanical actuated clutchesRotary clutchesFluid couplingEngineering

A hydrodynamic coupling device including: a housing; a sealing plate rotationally connected to the housing; a pump disposed within the housing; a turbine disposed within the housing and in fluid communication with the pump; and a dry chamber at least partially enclosed by the housing and the sealing plate. A hydrodynamic coupling device including: a housing; an electric motor rotationally connected to the housing; and a fluid coupling including a pump rotationally connected to the housing and a turbine rotationally connected to an output hub. The fluid coupling does not include a stator. A hydrodynamic coupling device including a space formed between a stator shaft and a pump hub and a sleeve disposed in the space. The sleeve divides the space into first and second channels.

Owner:SCHAEFFLER TECH AG & CO KG

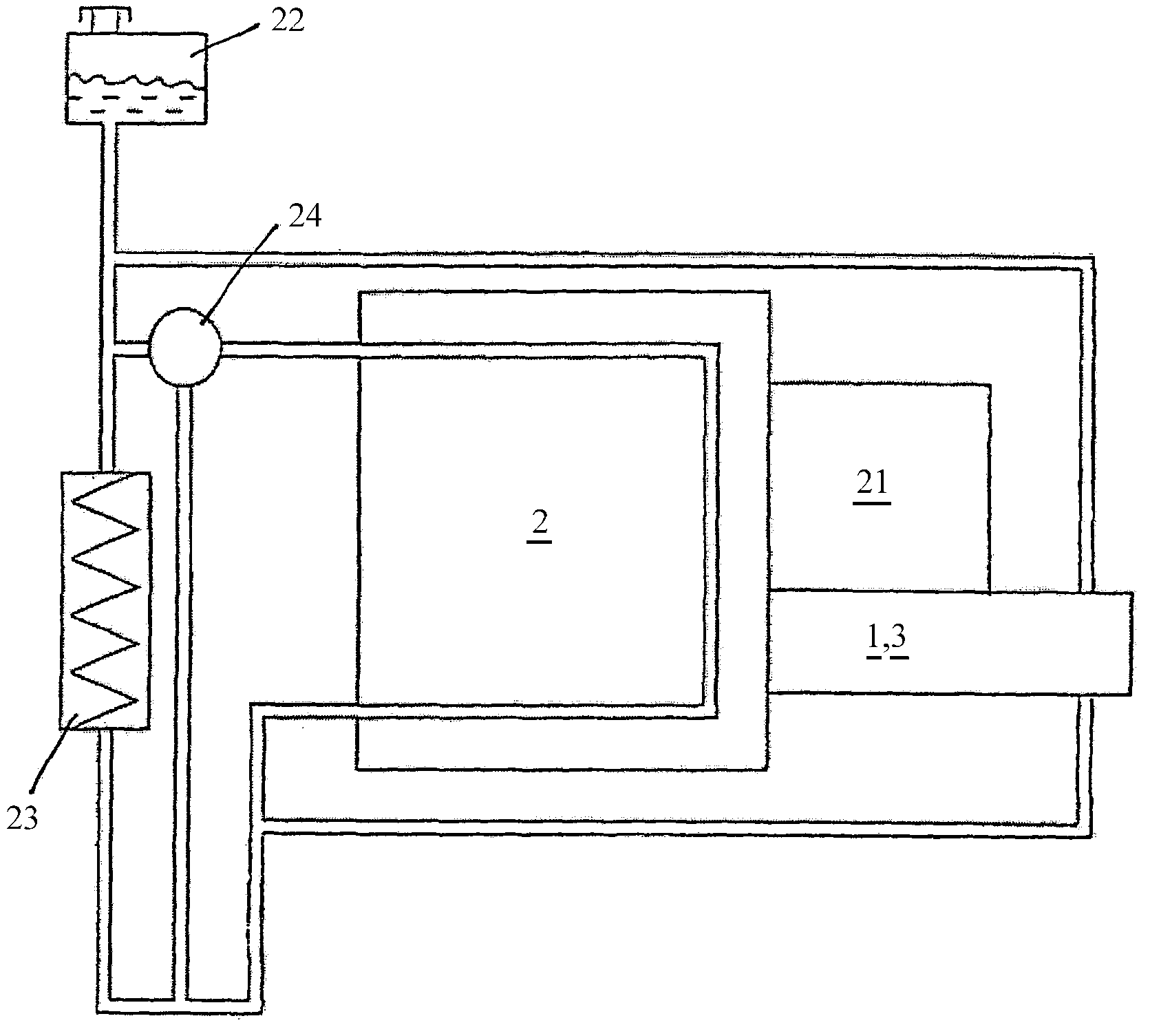

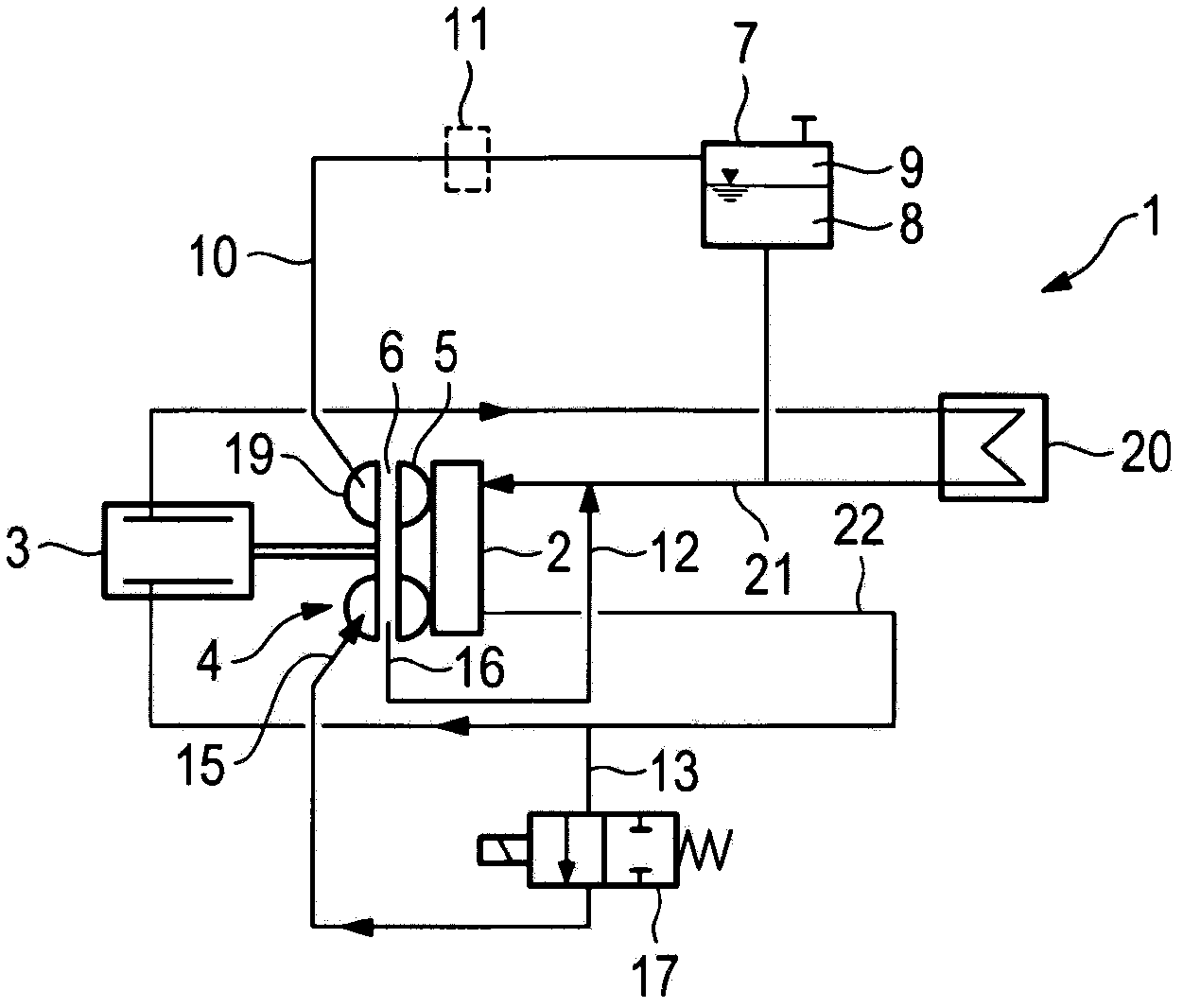

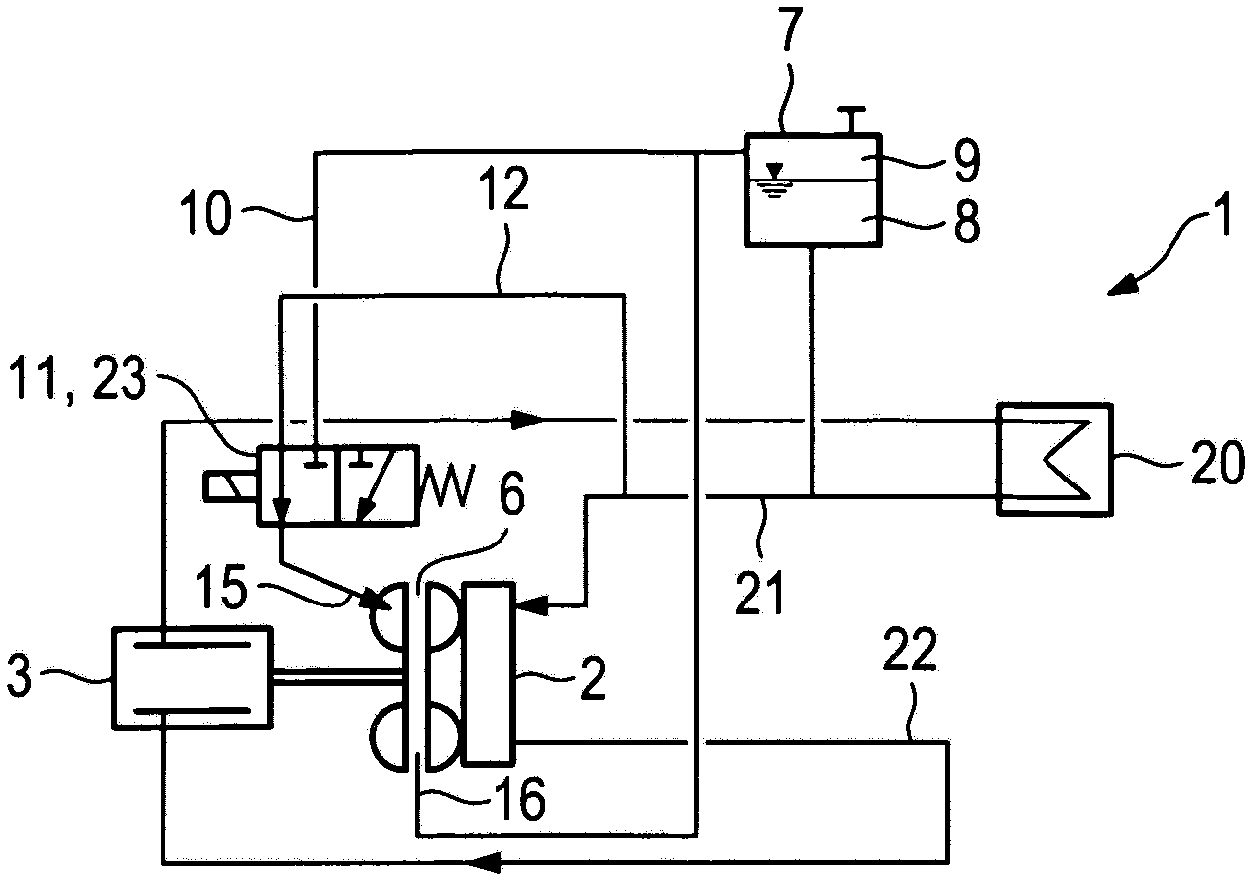

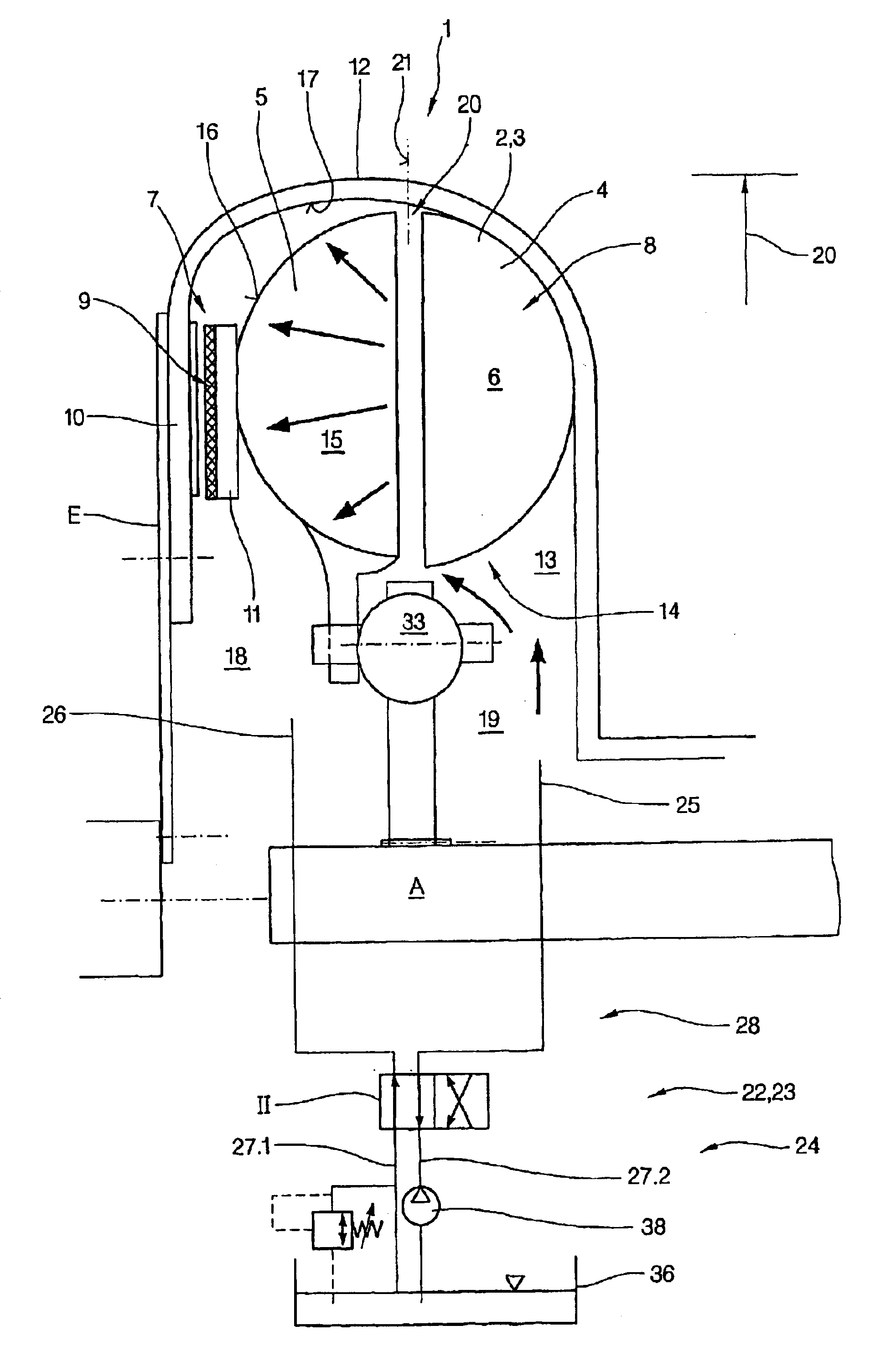

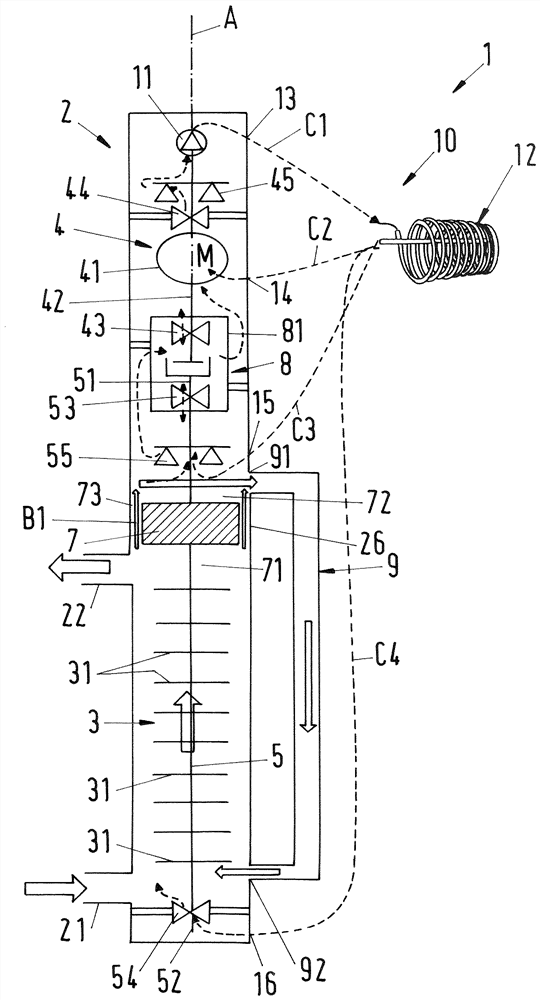

Vehicle cooling circuit with retarder or fluid coupling

The invention relates to a vehicle cooling circuit, in particular an engine cooling circuit, having a cooling medium circulated by a cooling medium pump in a cooling circuit; having a vehicle drive engine and / or other heat-generating assembly cooled by means of the cooling medium; having a hydrodynamic retarder, comprising a driven primary paddle wheel and a secondary paddle wheel, together forming a toroid-shaped workspace that can be filled with a working medium and from which said working medium can be withdrawn as desired in order to transfer torque hydrodynamically from said primary paddle wheel to said secondary paddle wheel; wherein said working medium of the hydrodynamic retarder is also the cooling medium of the cooling circuit; and the hydrodynamic retarder also operates as the cooling medium pump and brings about a pumping effect on the cooling medium for circulating the cooling medium in the cooling circuit. The invention is characterized by the following features: a brake or a drive running counter to the drive of the primary paddle wheel is associated with the secondary paddle wheel such that it can be fixed in a first operating condition - brake mode - or driven counter to the rotation direction of the primary paddle wheel in order to hydrodynamically brake the primary paddle wheel and, in a second operating condition - pump mode - can be partially or completely released such that it circulates at the speed of the primary paddle wheel or at a specified speed difference slower than the primary paddle wheel together with the primary paddle wheel in the same direction.

Owner:VOITH PATENT GMBH

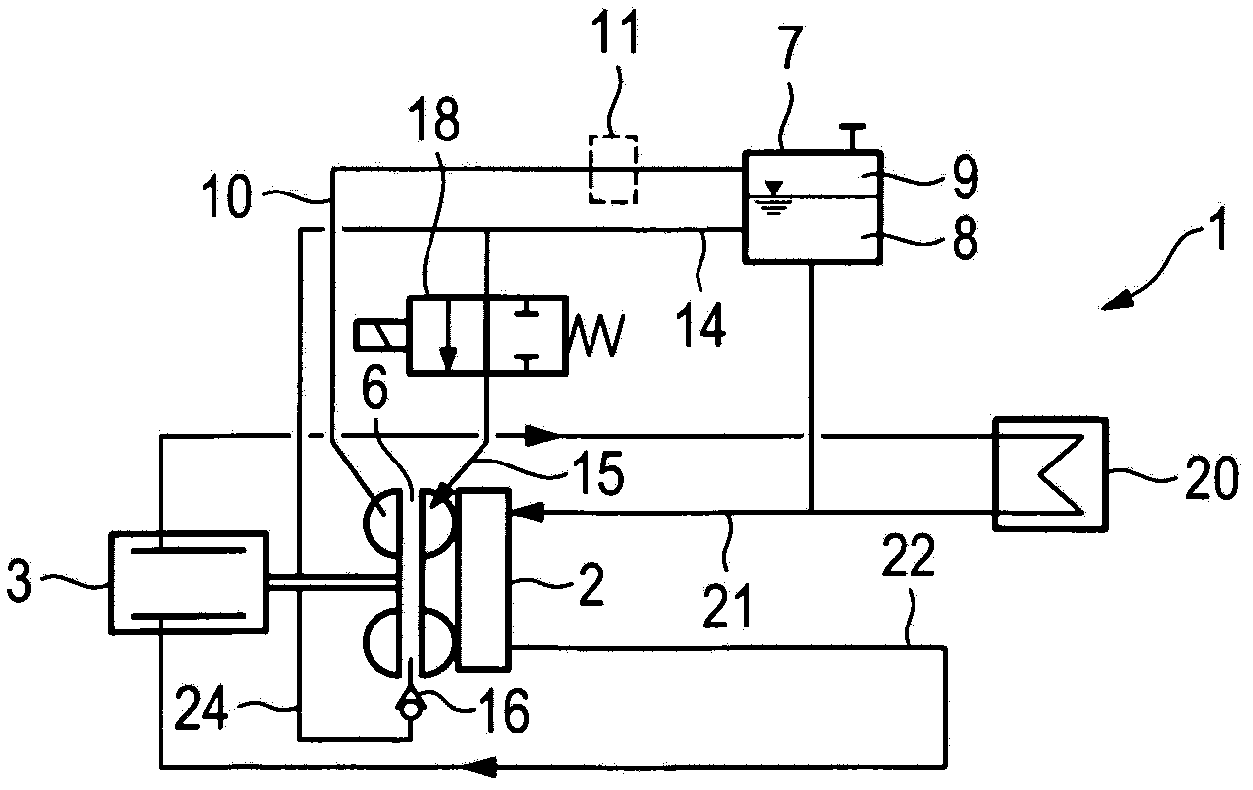

Cooling system, in particular for a motor vehicle

The invention relates to a cooling system, in particular a motor vehicle cooling system, having a cooling circuit in which a cooling medium is circulated by means of a cooling medium pump; the cooling medium pump or another work machine being driven by means of a drive machine via a hydrodynamic coupling, comprising a pump impeller driven by the drive machine and a turbine wheel driven by the cooling medium pump, which together form a toroidal working chamber that can optionally be filled with working medium; the working medium being the cooling medium; having a compensating container, comprising a space filled with cooling medium and an air chamber above a cooling medium level in the chamber filled with the cooling medium. The invention is characterized in that the working chamber of the hydrodynamic coupling is always connected to the air chamber or can optionally be connected to the latter via an air-conducting connection.

Owner:VOITH PATENT GMBH

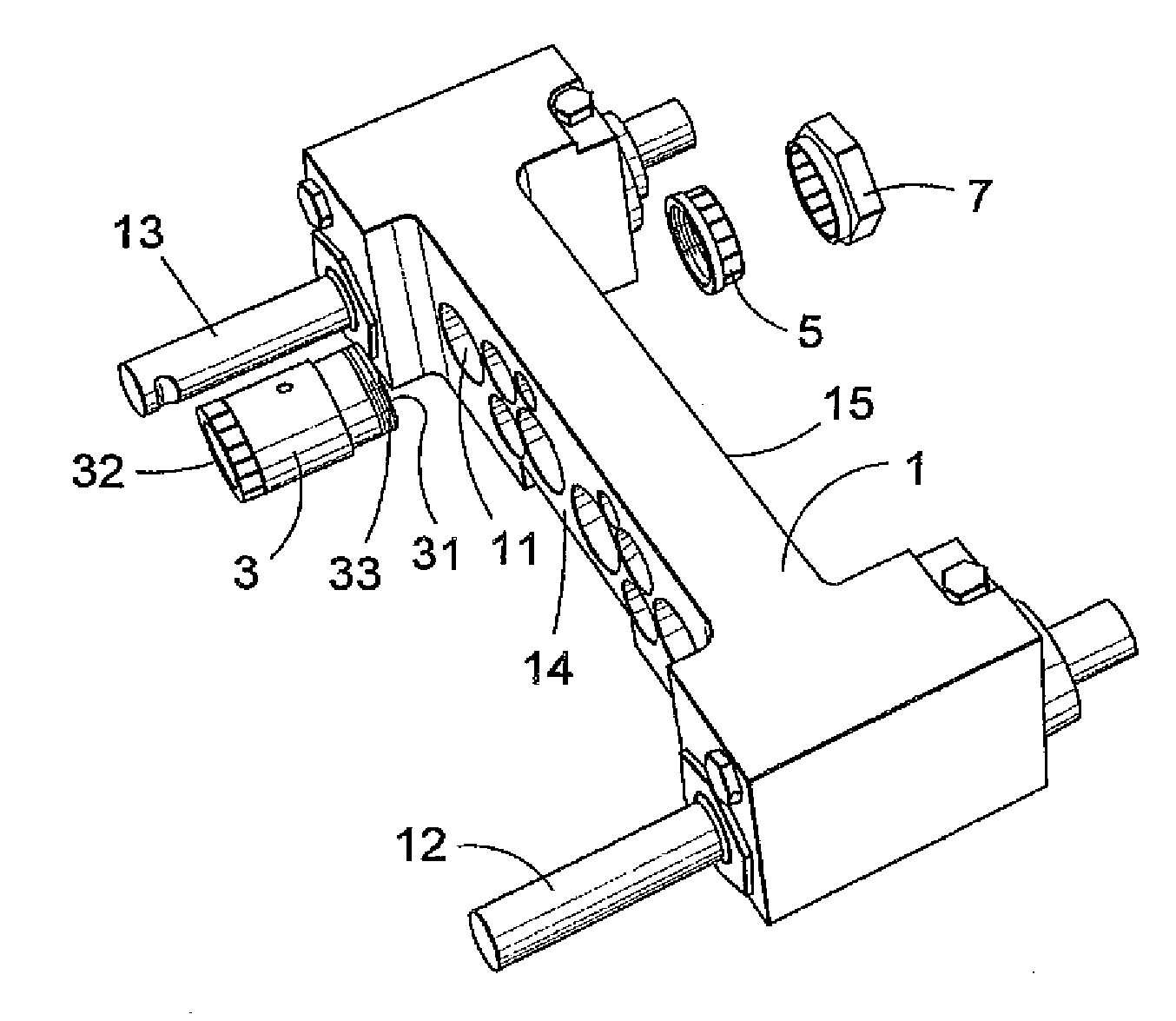

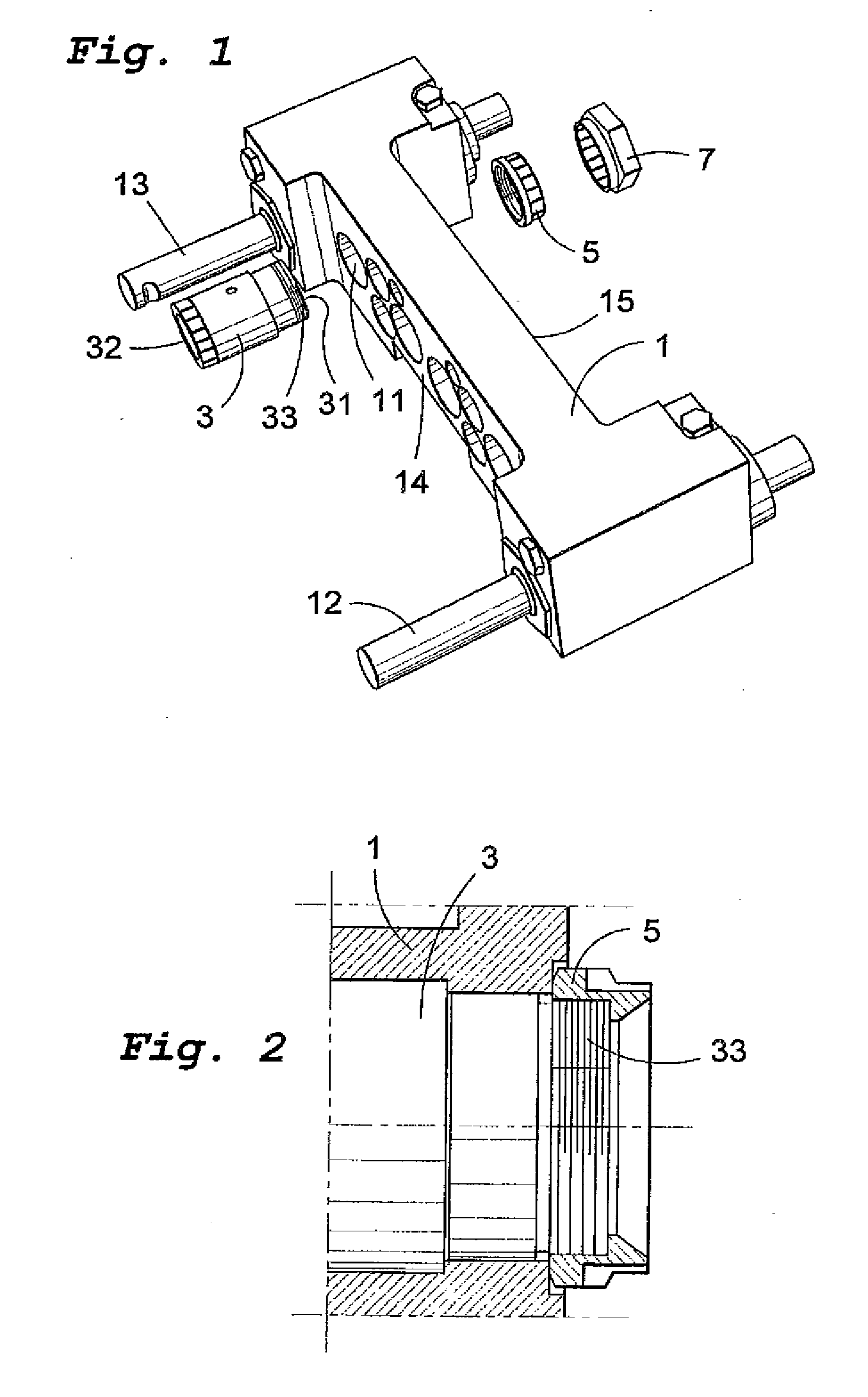

Hydraulic coupling device and components and method related thereto

ActiveUS20090058075A1Uniform application of torqueEliminate disadvantagesNutsPipe elementsCouplingEngineering

A hydraulic coupling device, comprising a coupling unit, a holder block, and a lock nut. The coupling unit is mounted to the holder block by means of the lock nut, which is tightened in a thread at the nose end of the coupling unit. The lock nut has a rotationally symmetrical outer contour. A plurality of grooves distributed around the circumference are recessed in the outer contour. The grooves extend axially inward from the end of the lock nut facing away from the holder block. The invention also relates to a lock nut for a hydraulic coupling device, a mounting tool for the lock nut as well as a method for mounting a hydraulic coupling device.

Owner:OILQUICK

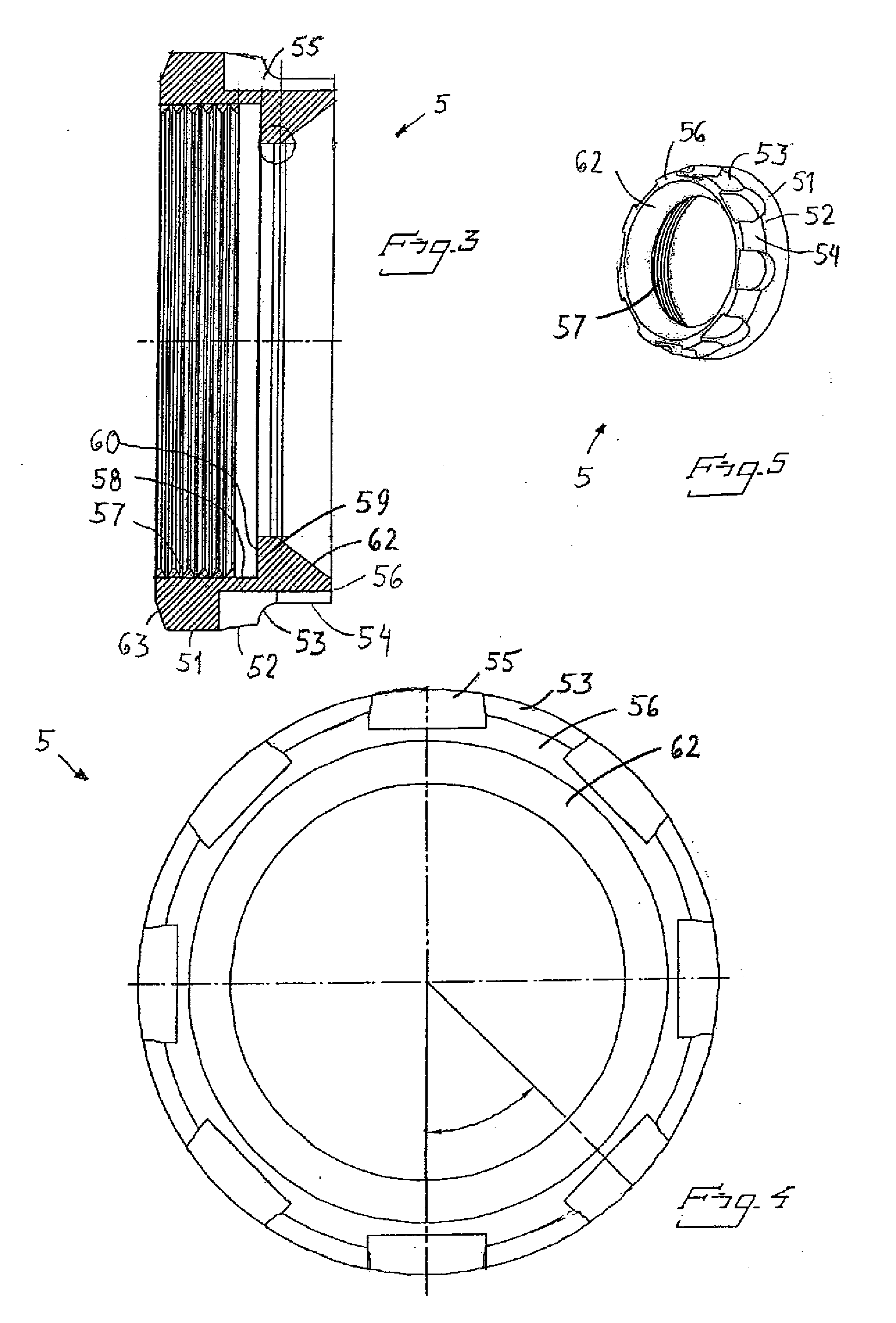

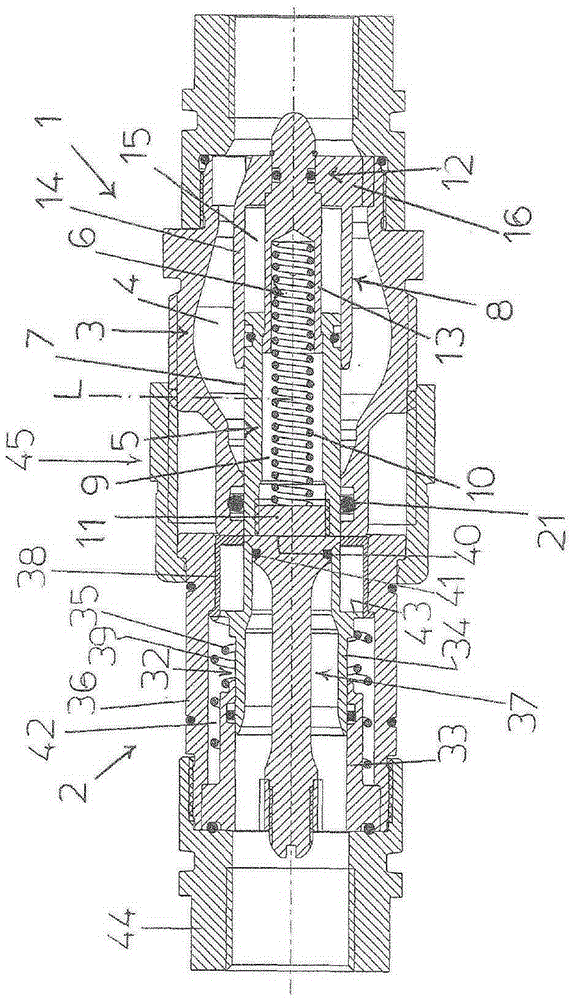

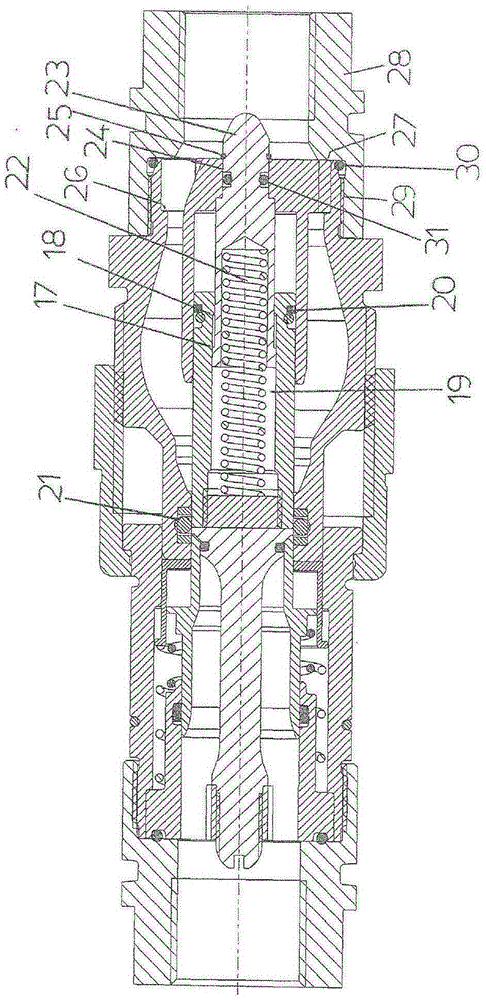

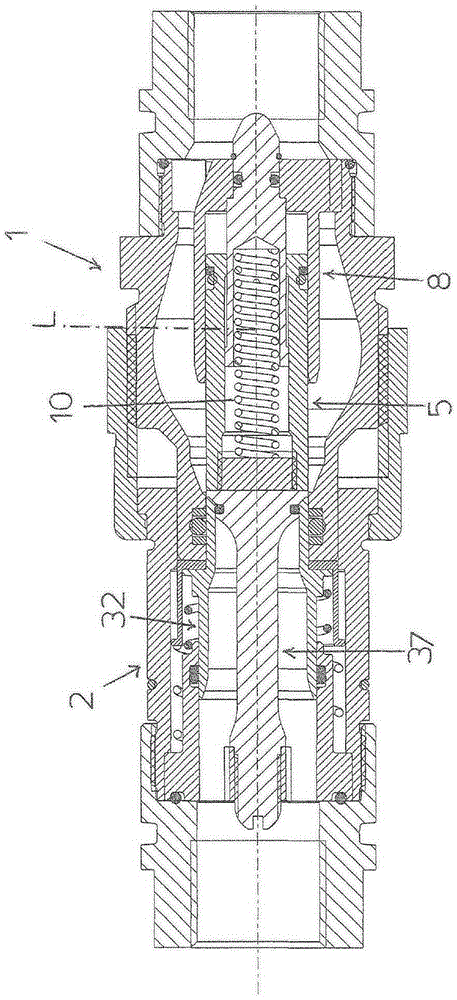

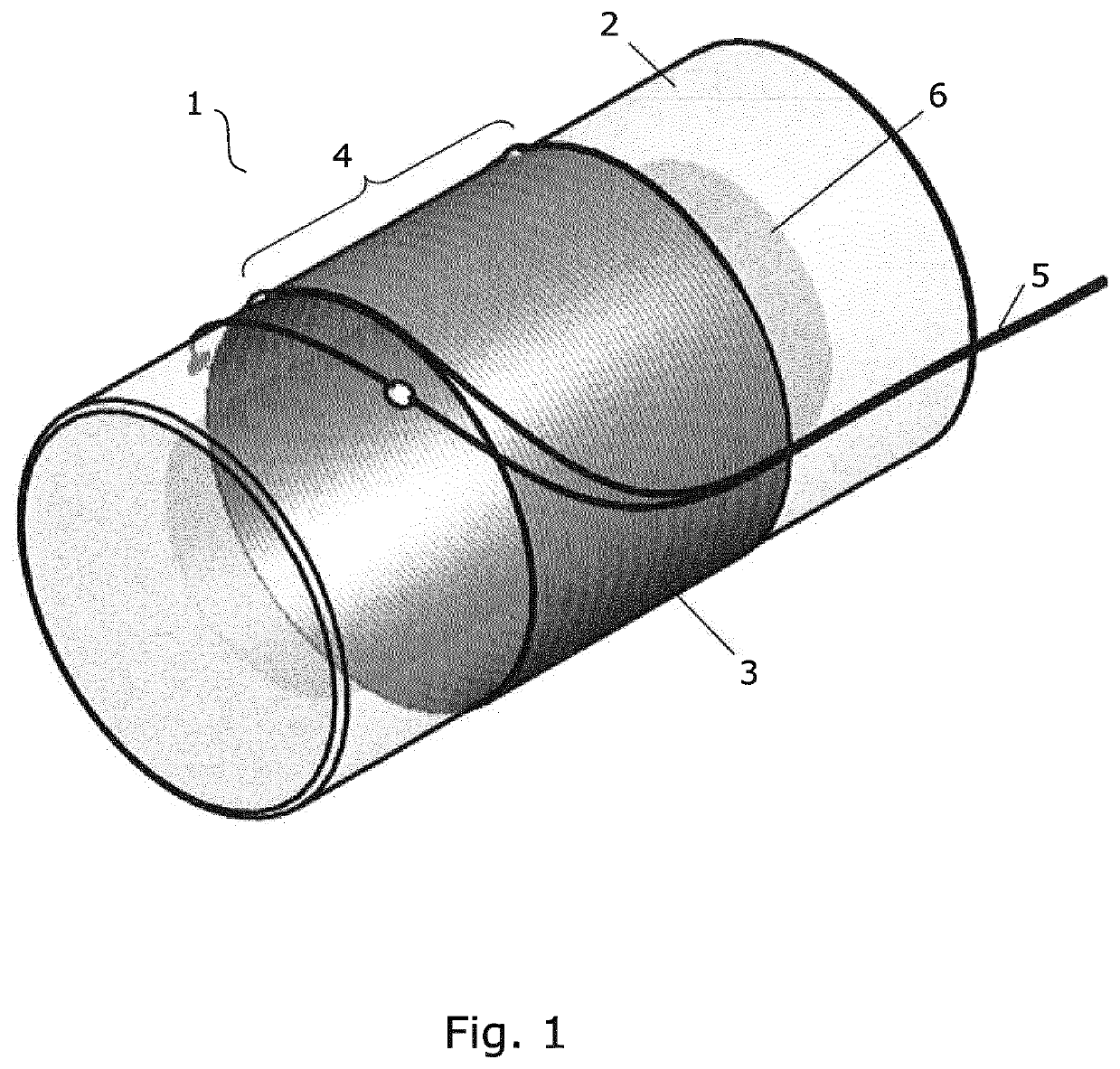

Quick-fit hydraulic or hydrodynamic coupling for pressurised fluids

ActiveCN105378363AEliminate routine problemsSleeve/socket jointsOperating means/releasing devices for valvesFluid couplingHydraulic pressure

The quick-fit coupling (1) for pressurised fluid comprises a valve body (3) extending along a longitudinal axis (L) and having an axial cavity (4) wherein a shutter stem (5) is axially movable with respect to the valve body in contrast to and by action of at least one elastic element (6) between a position for opening and a position for closing an axial passage of fluid through said cavity (4), the stem (5) being configured so as to be subjected by the fluid present in the cavity (4) to a resultant force having a substantially null component at least in an axial direction.

Owner:ALFAGOMMA

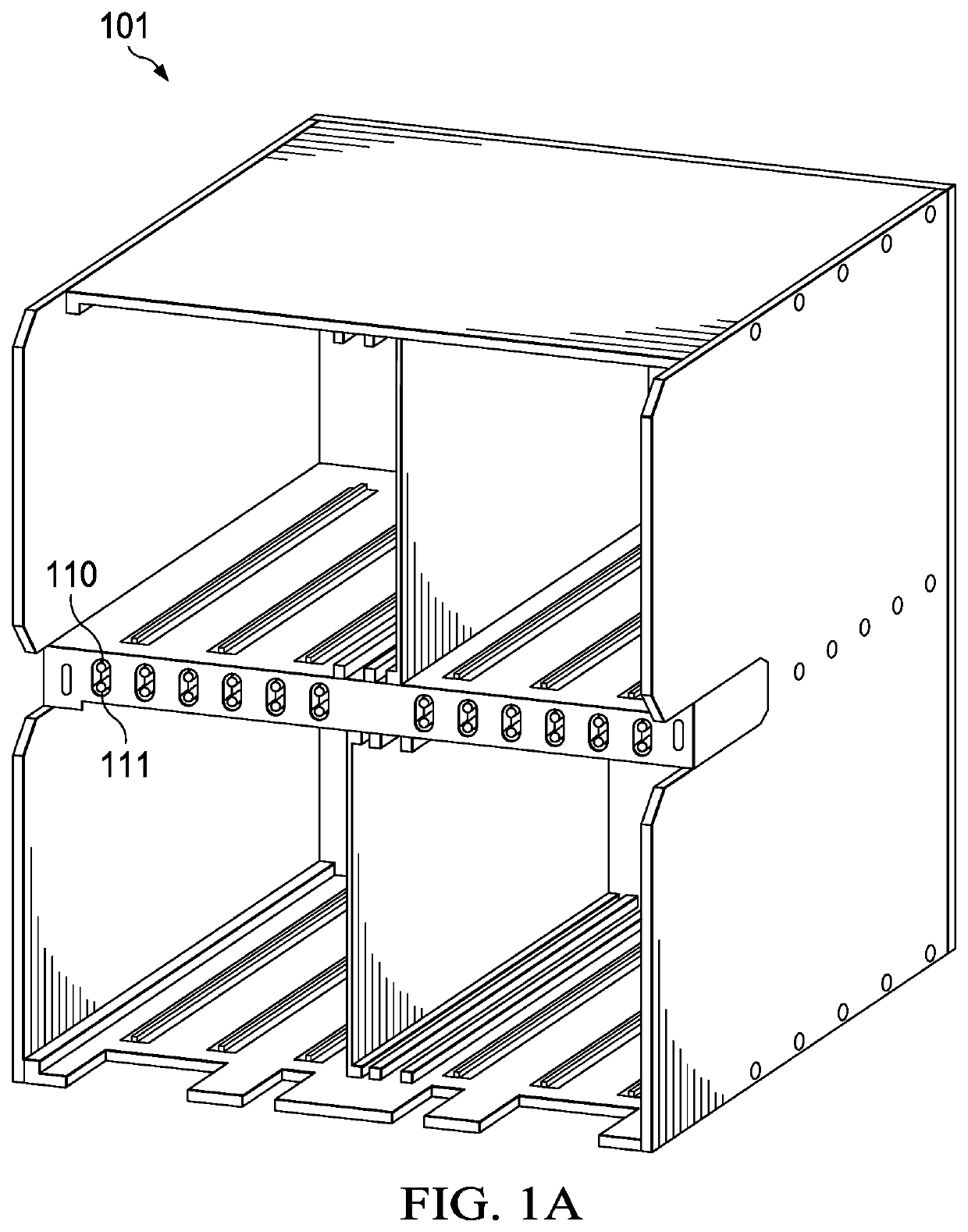

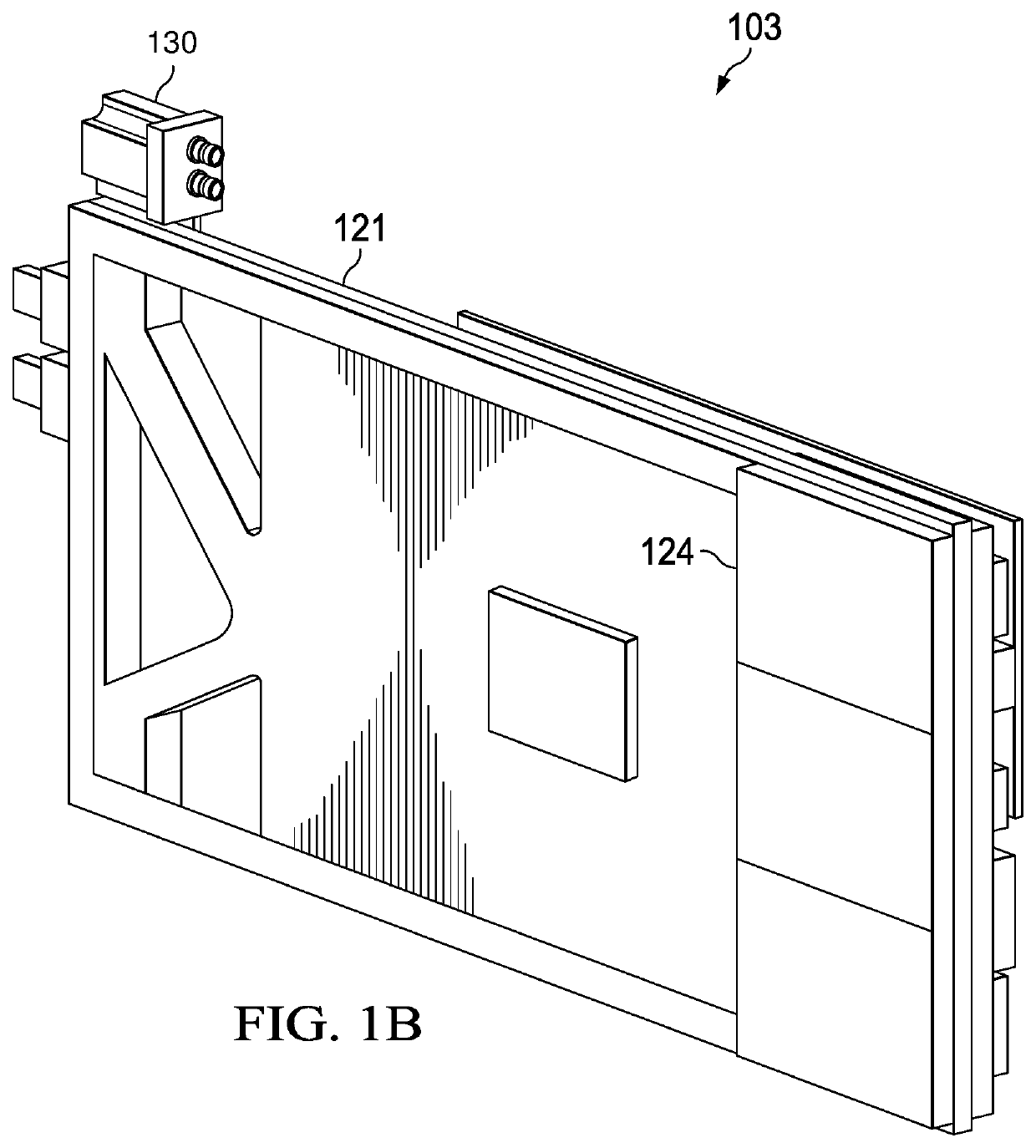

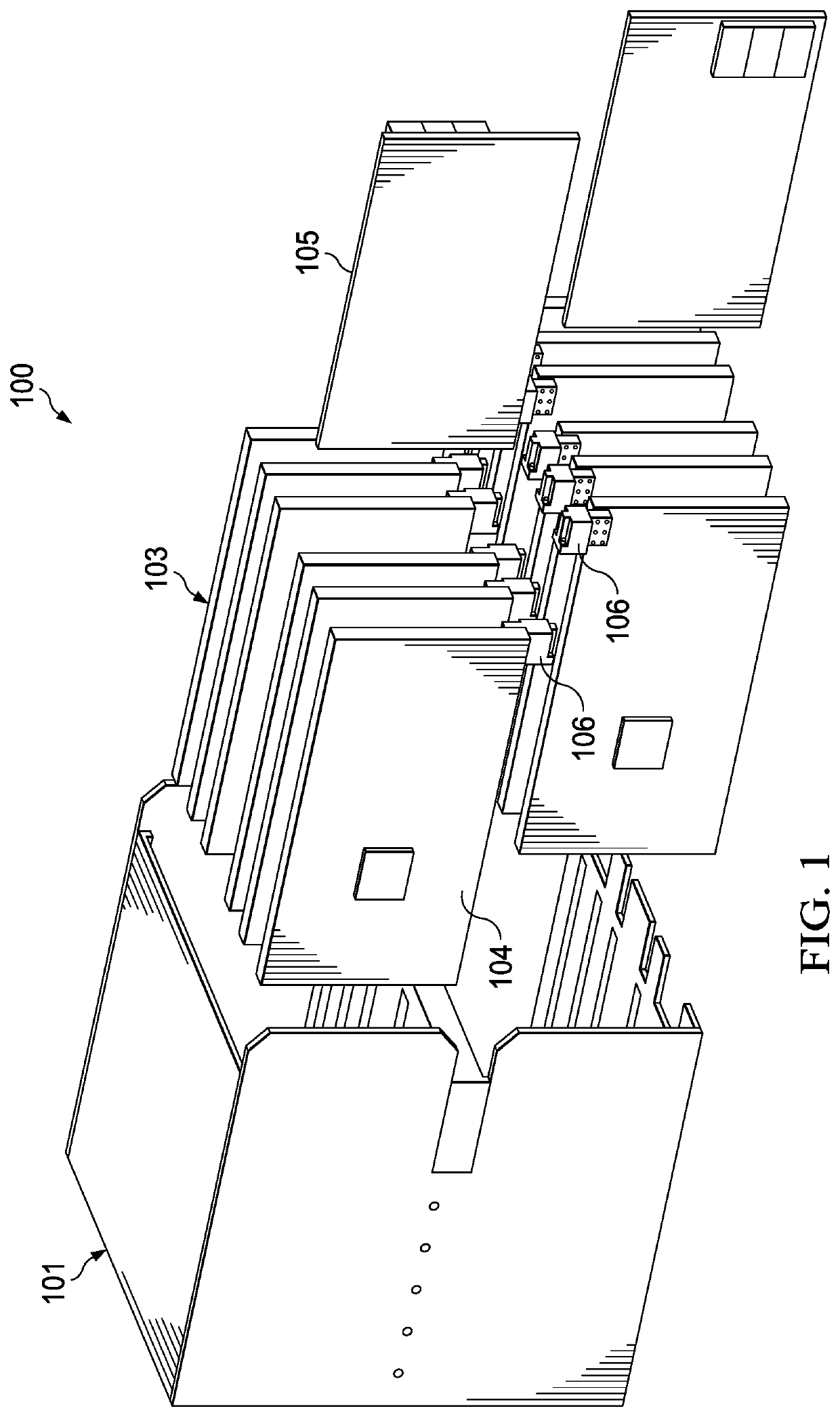

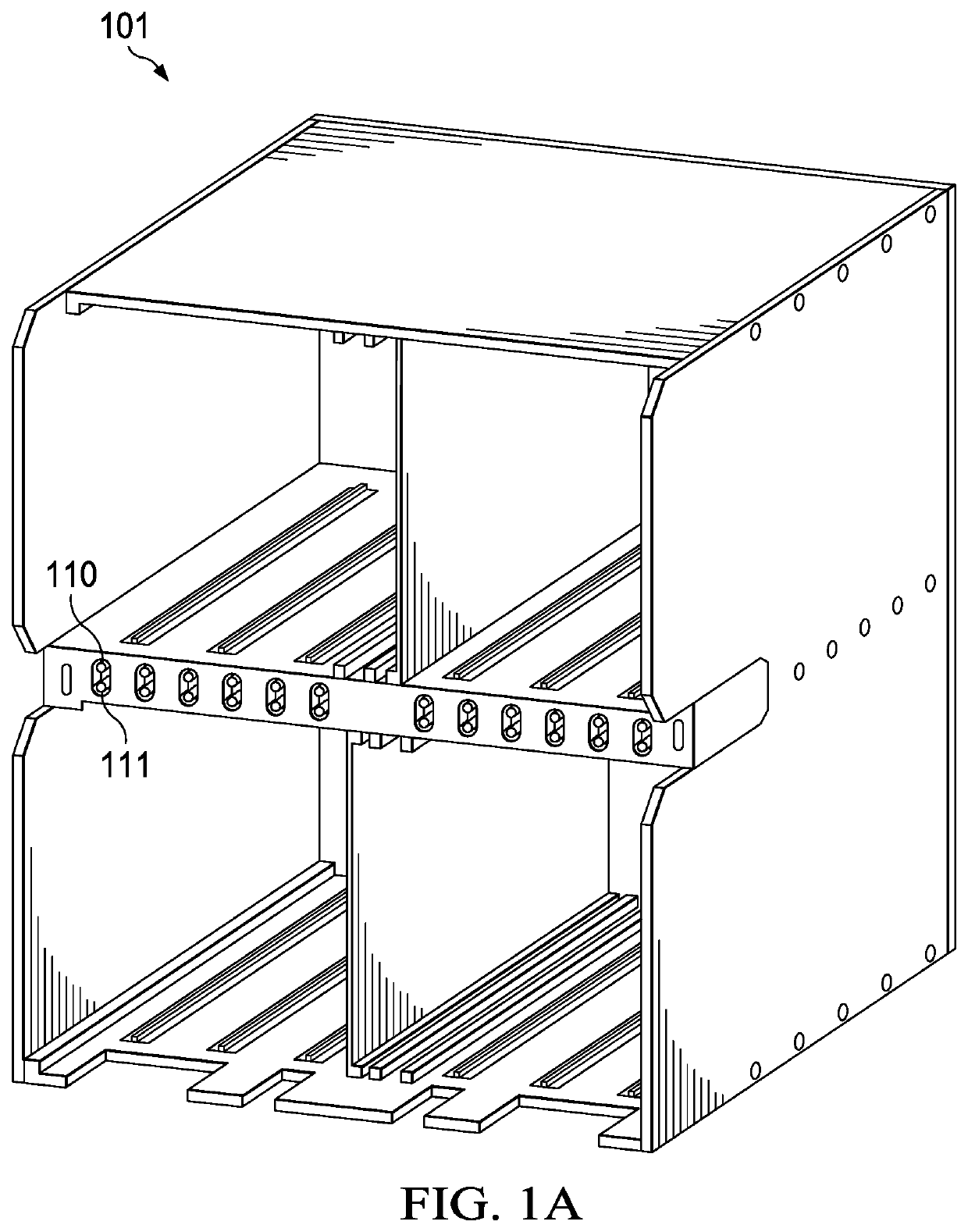

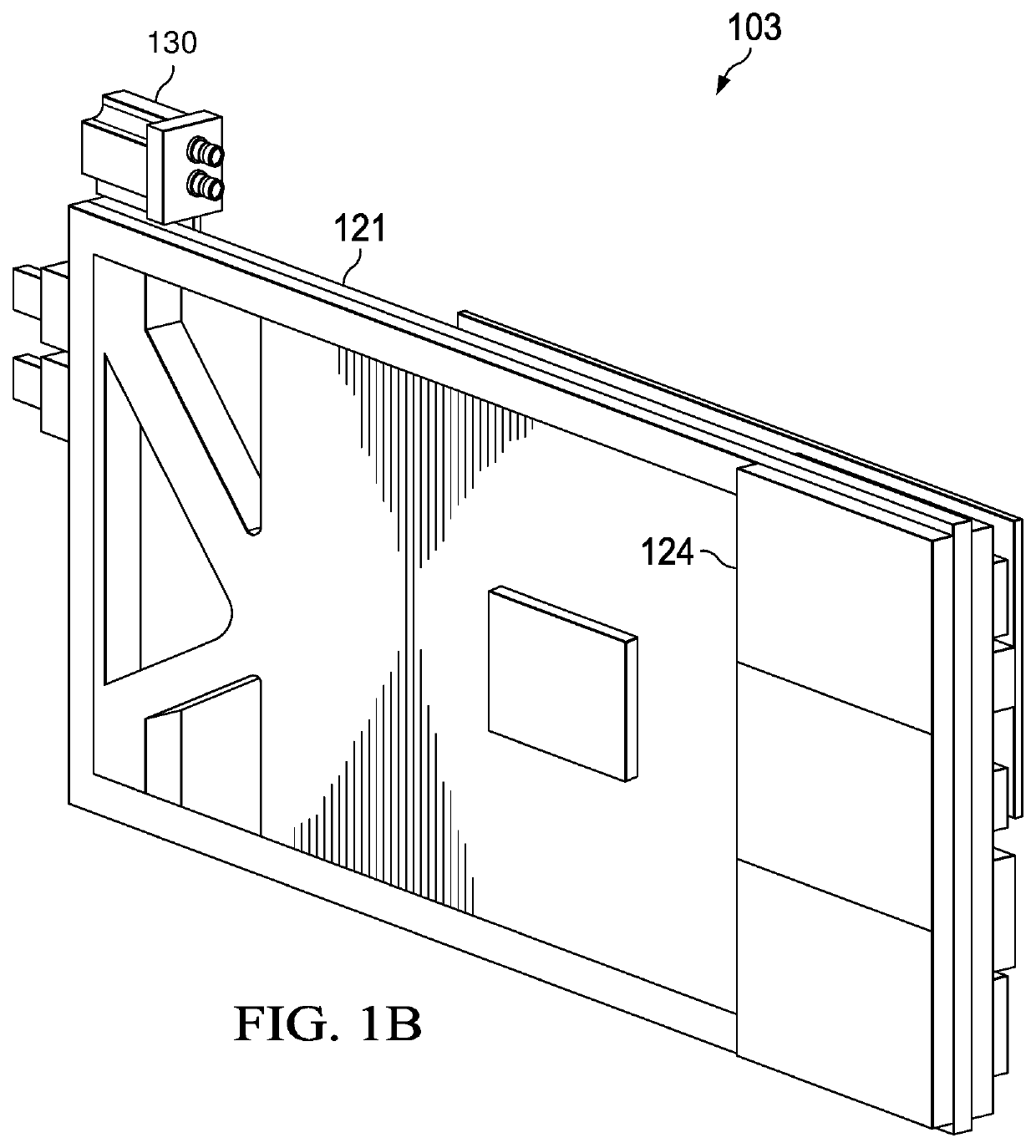

Multi-purpose coolant interface

A coolant interface includes a line replaceable unit (LRU) inserted into a slot within a modular assembly such as a chassis for an electronics assembly. Quick disconnect fluid coupling fittings on the LRU mate with counterpart fittings on a fluid distribution manifold within the chassis when the LRU is inserted into the slot. A seal surrounding the quick disconnect fluid coupling fittings on a flat surface abutting a counterpart surface on the fluid distribution manifold when the LRU is inserted into the slot compresses the seal against the counterpart surface. Alignment pin(s) projecting from the flat surface and received by corresponding guide holes within the counterpart surface, and captive hardware provides pressure between the flat surface and the counterpart surface to increase and maintain compression of the seal. The alignment pins and captive hardware are arranged to increase mechanical stability of the connection.

Owner:RAYTHEON CO

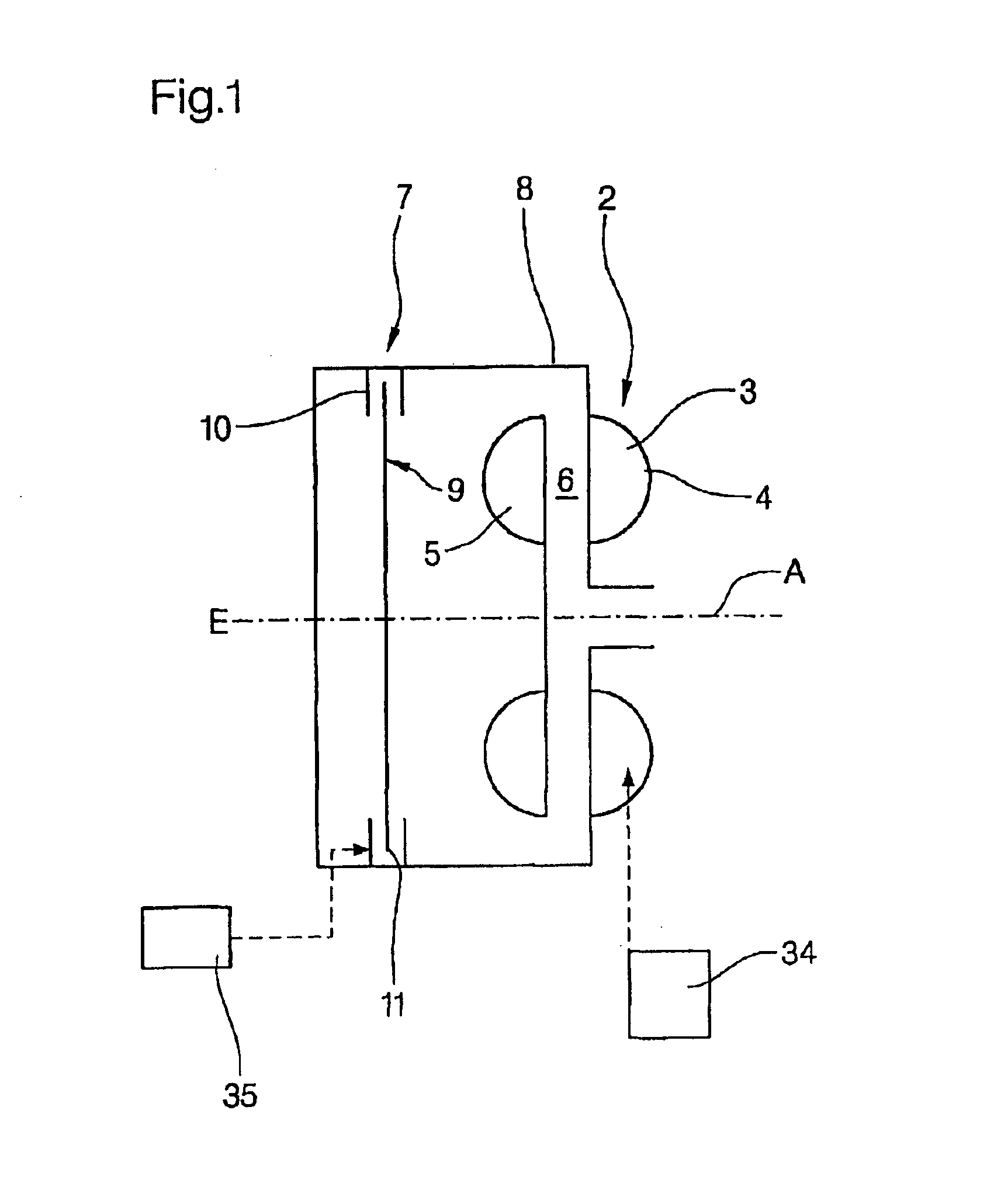

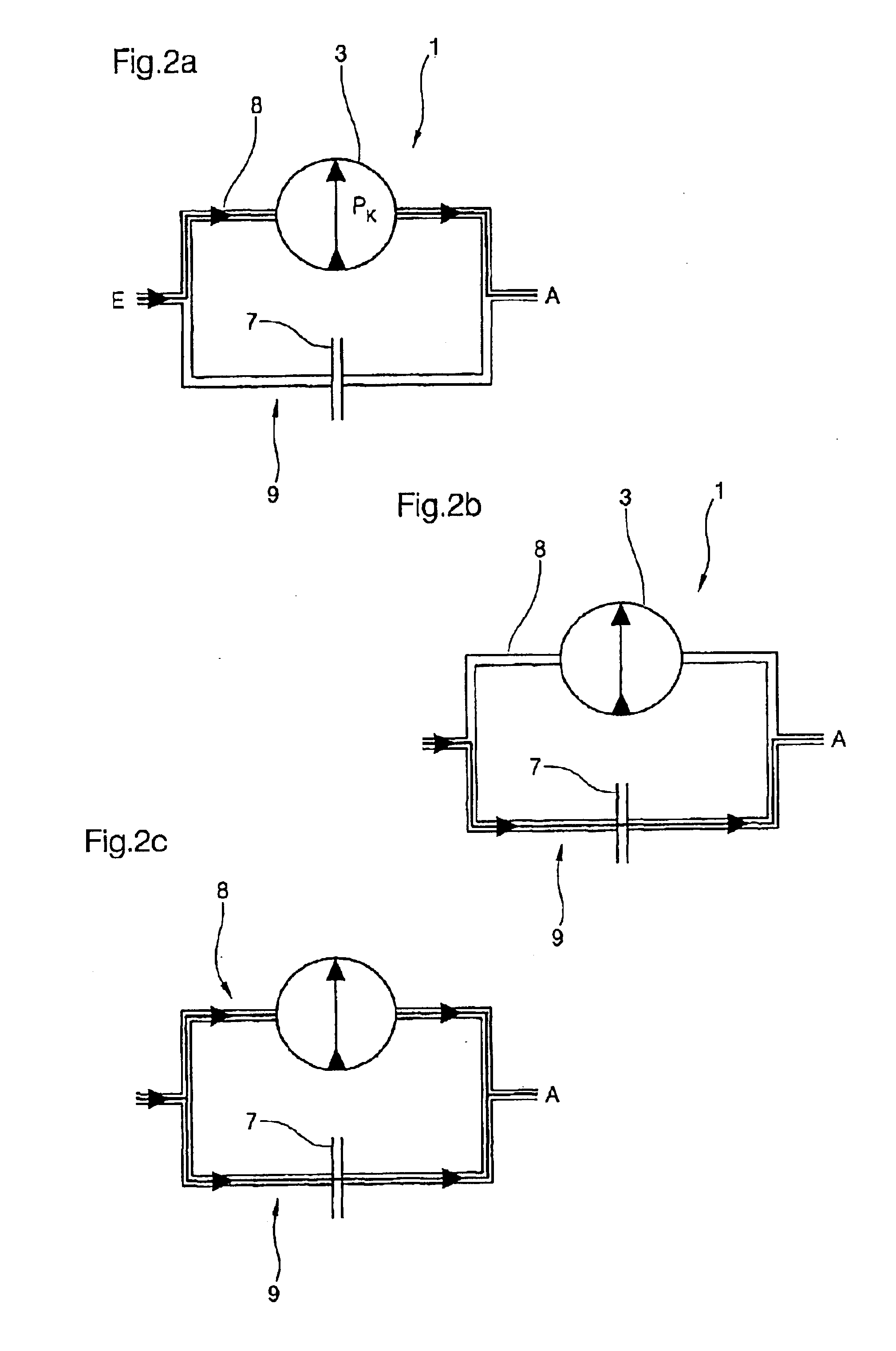

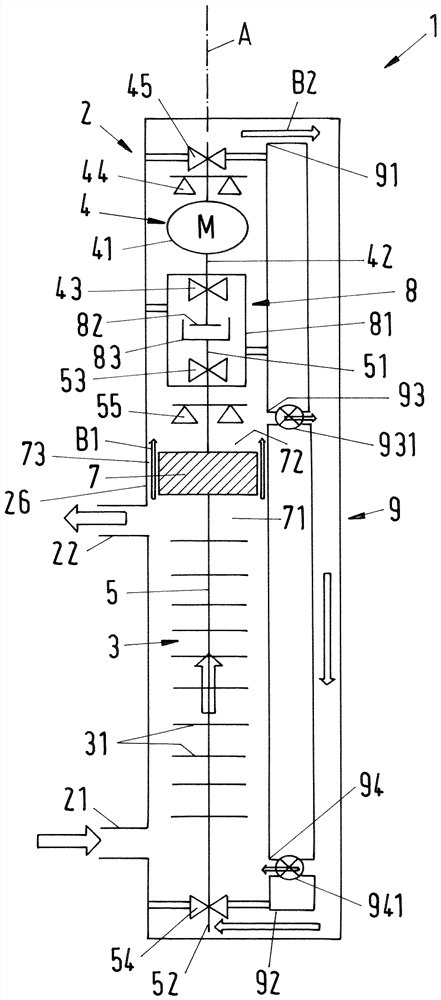

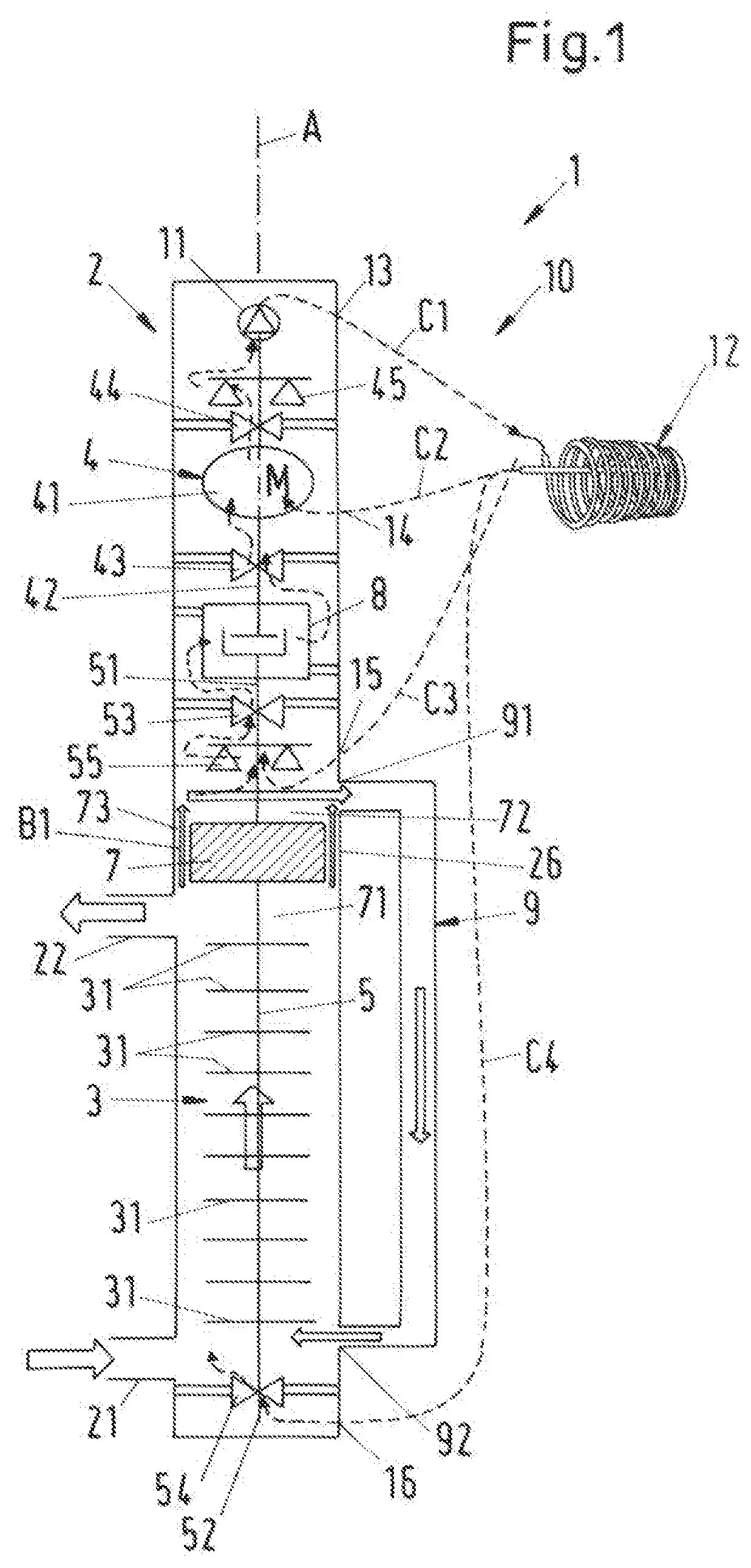

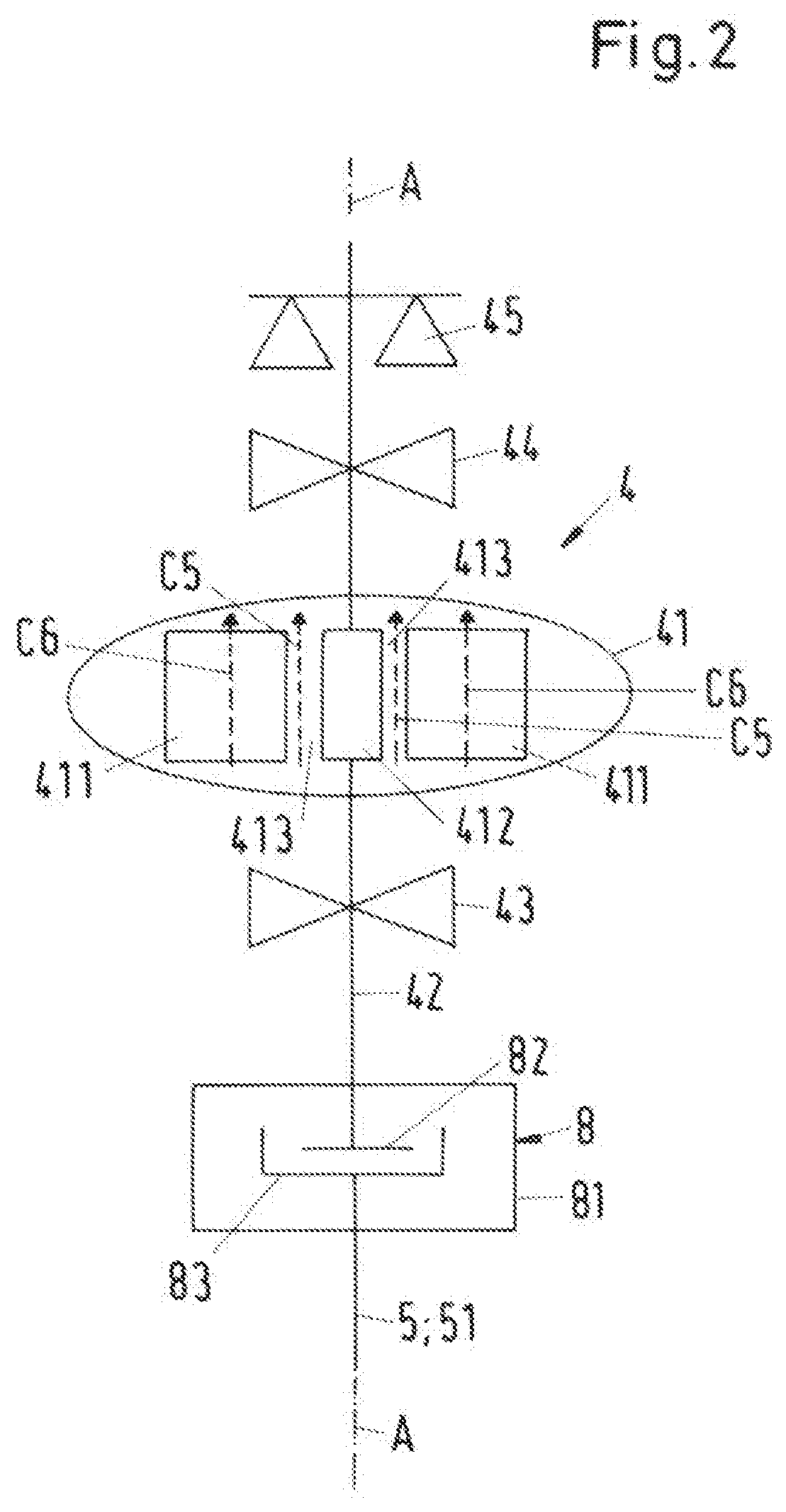

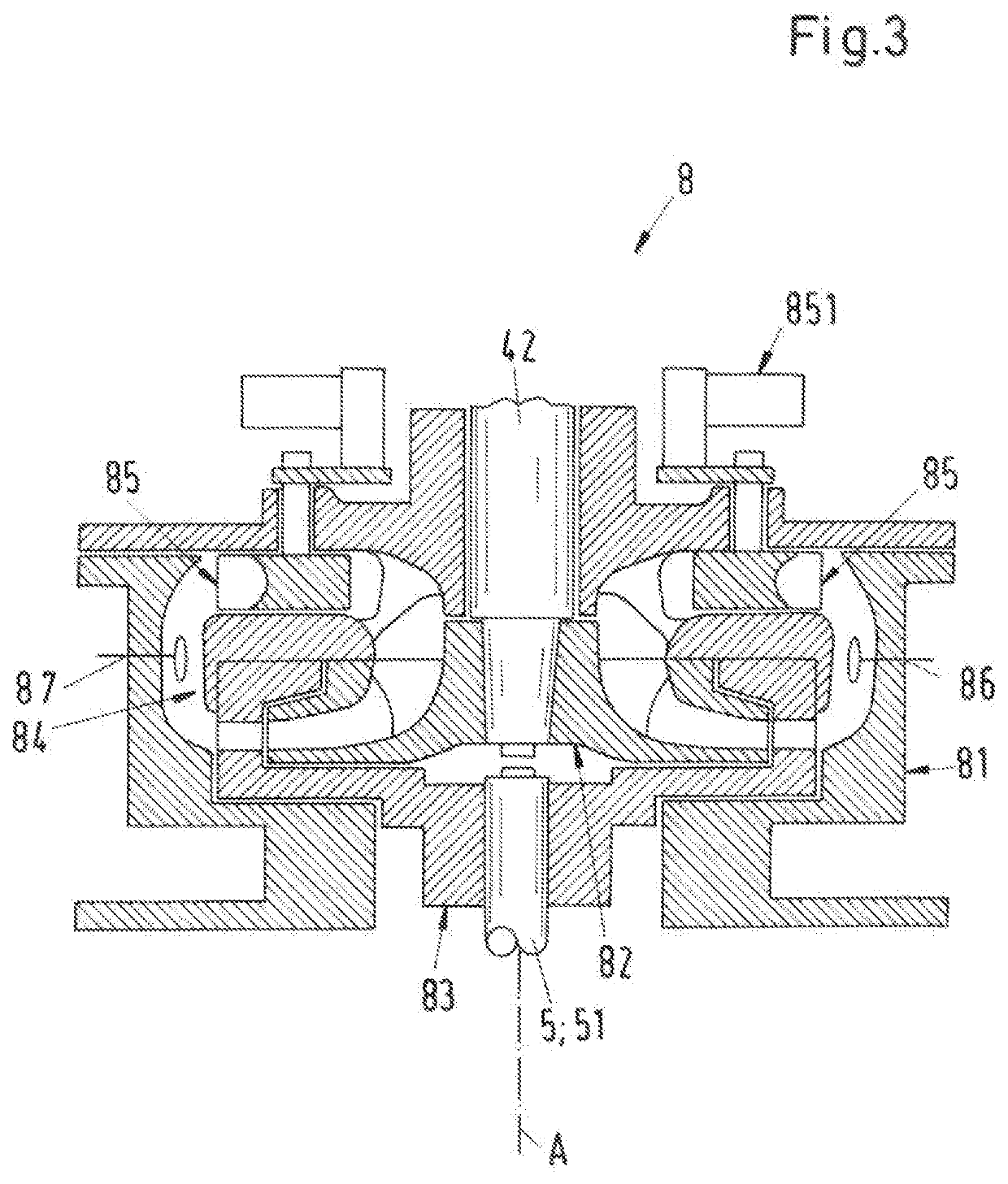

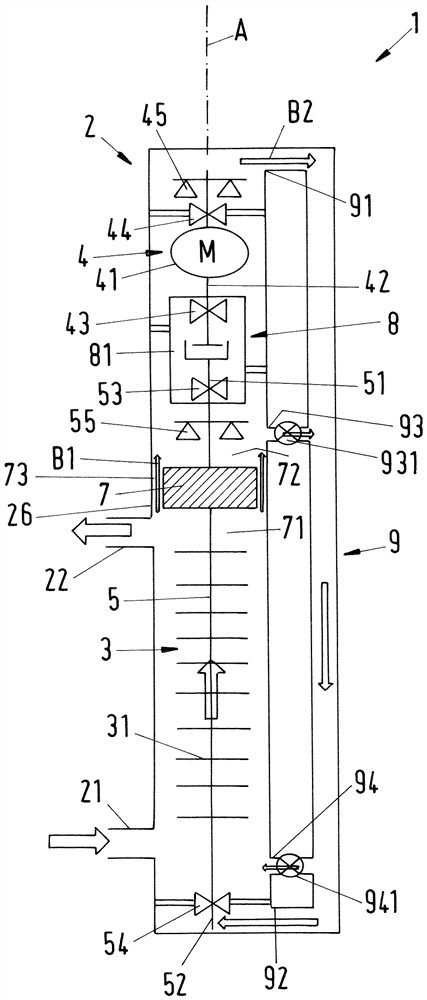

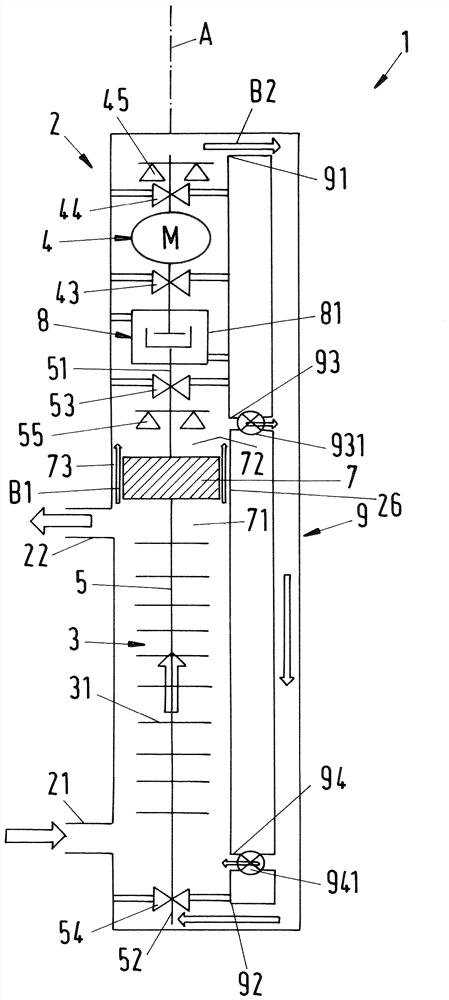

Starter unit and method for matching starter units in drive systems to different limiting conditions, in particular different drive engines

The invention relates to a starter unit (1) comprising an input (E) which may be coupled to a drive input, an output (A) which may he coupled to a drive output, a starter element (2) in the form of a hydrodynamic coupling (3), a switchable clutch (7), comprising at least two clutch elements, which may be brought into frictional engagement, either directly or indirectly, by means of further transfer agents, being a first clutch element (10) and a second clutch element (11) each rotationally fixed to the input (E) and the output (A) respectively. The hydrodynamic coupling (3) and the switchable clutch (7) are arranged in a parallel fashion in two power branches (8,9) and may be activated individually or in common.

Owner:VOITH TURBO GMBH & CO KG

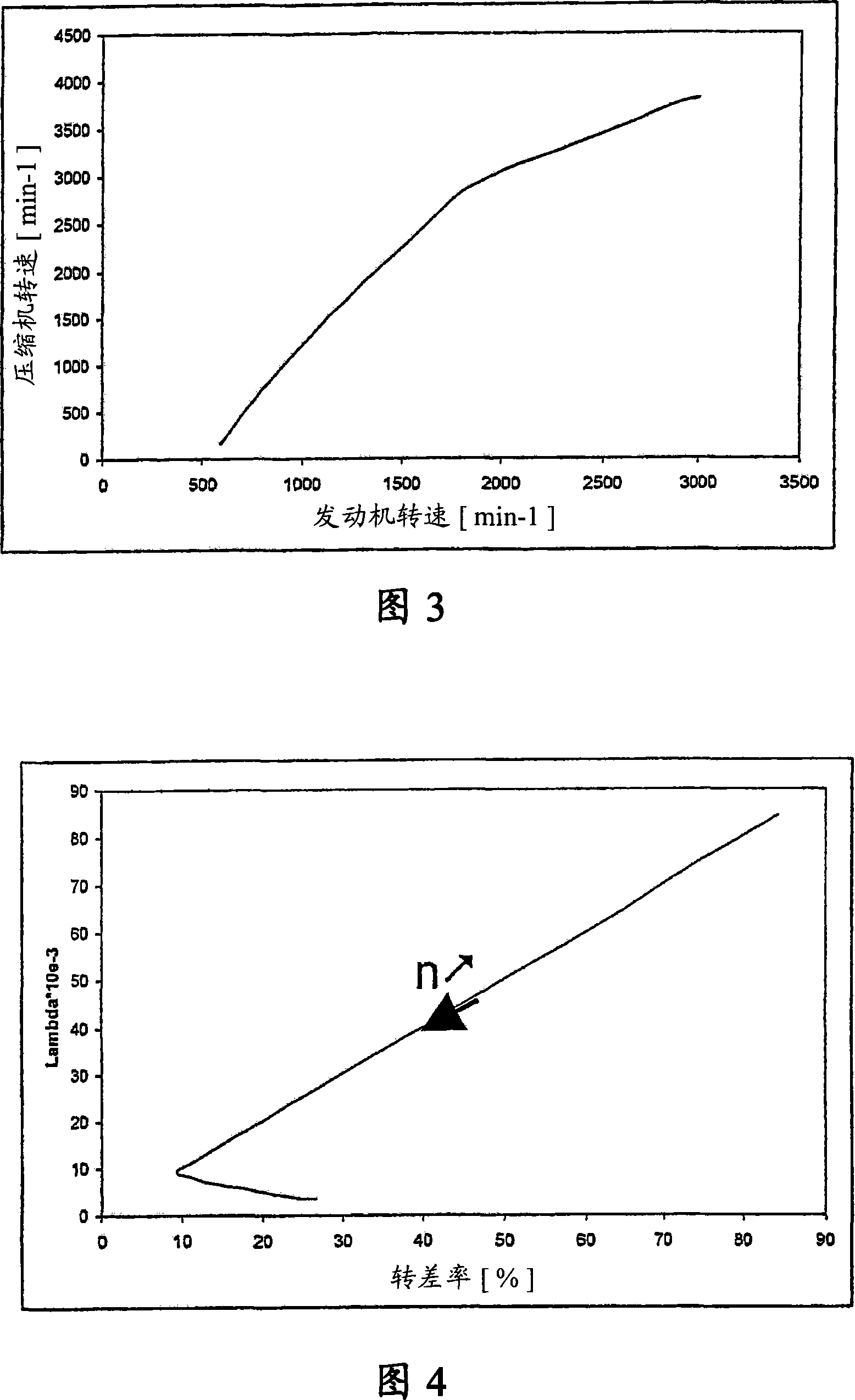

Method for regulating the maximum speed of a working machine and associated hydrodynamic coupling

Owner:VOITH TURBO GMBH & CO KG

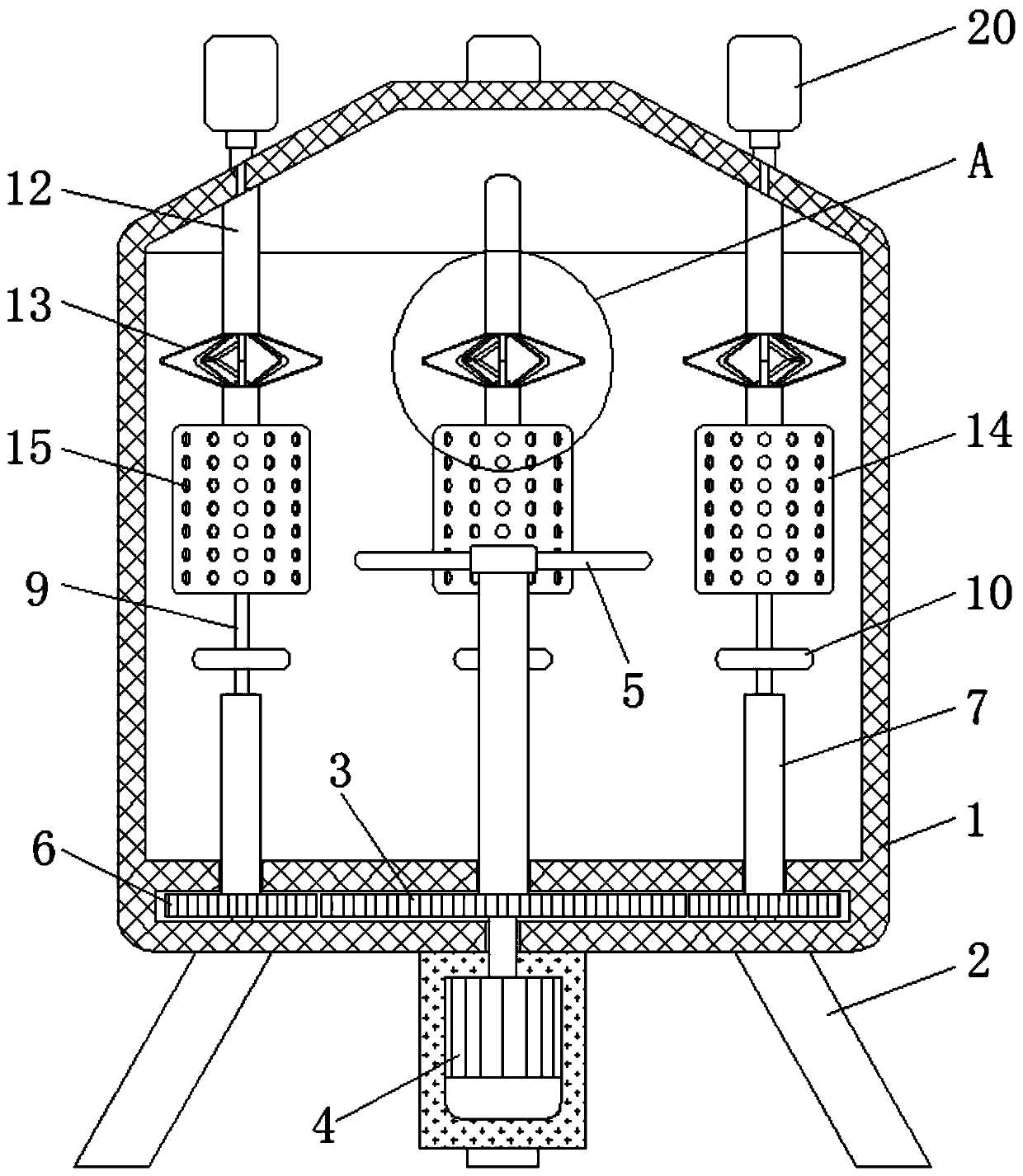

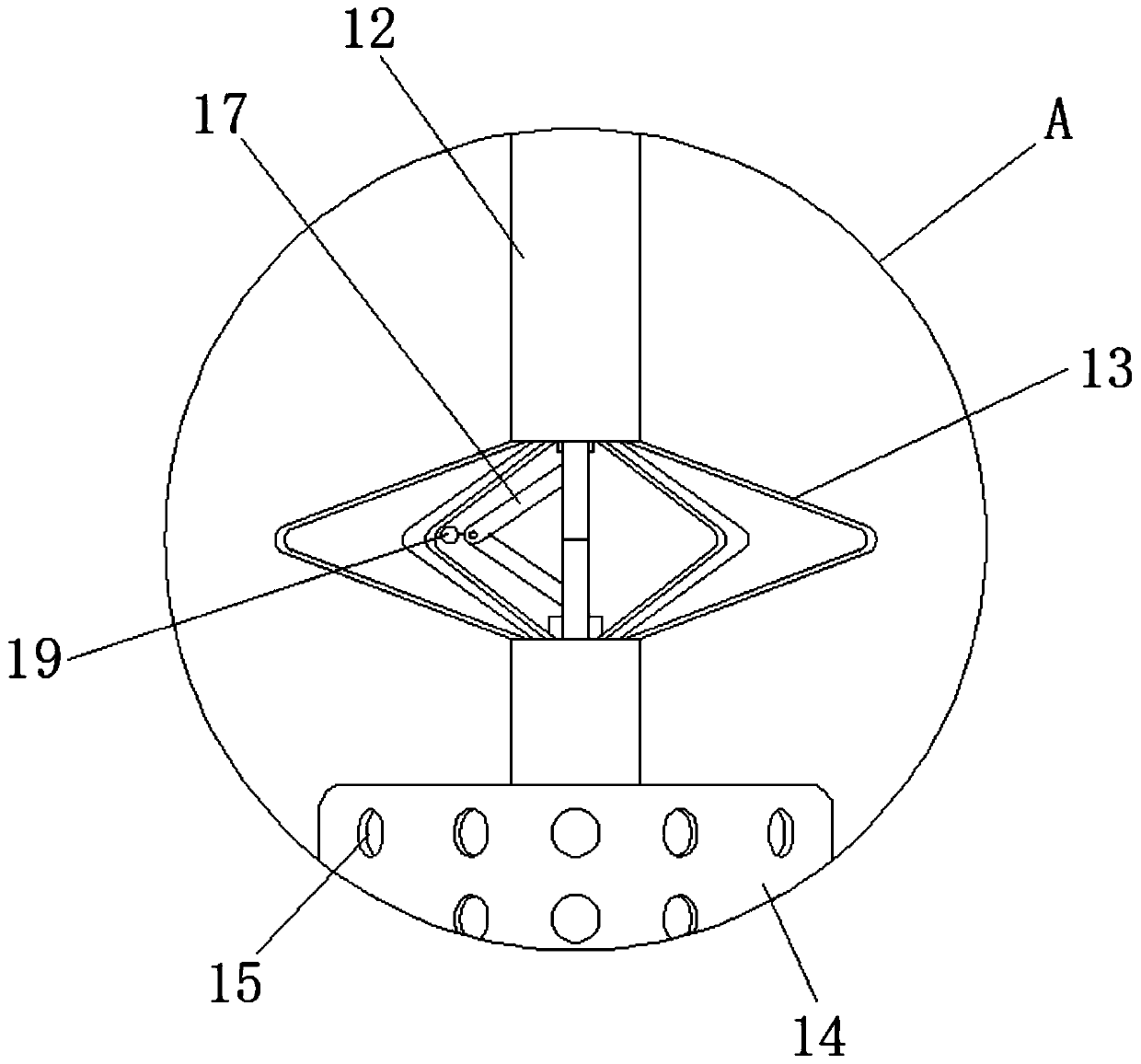

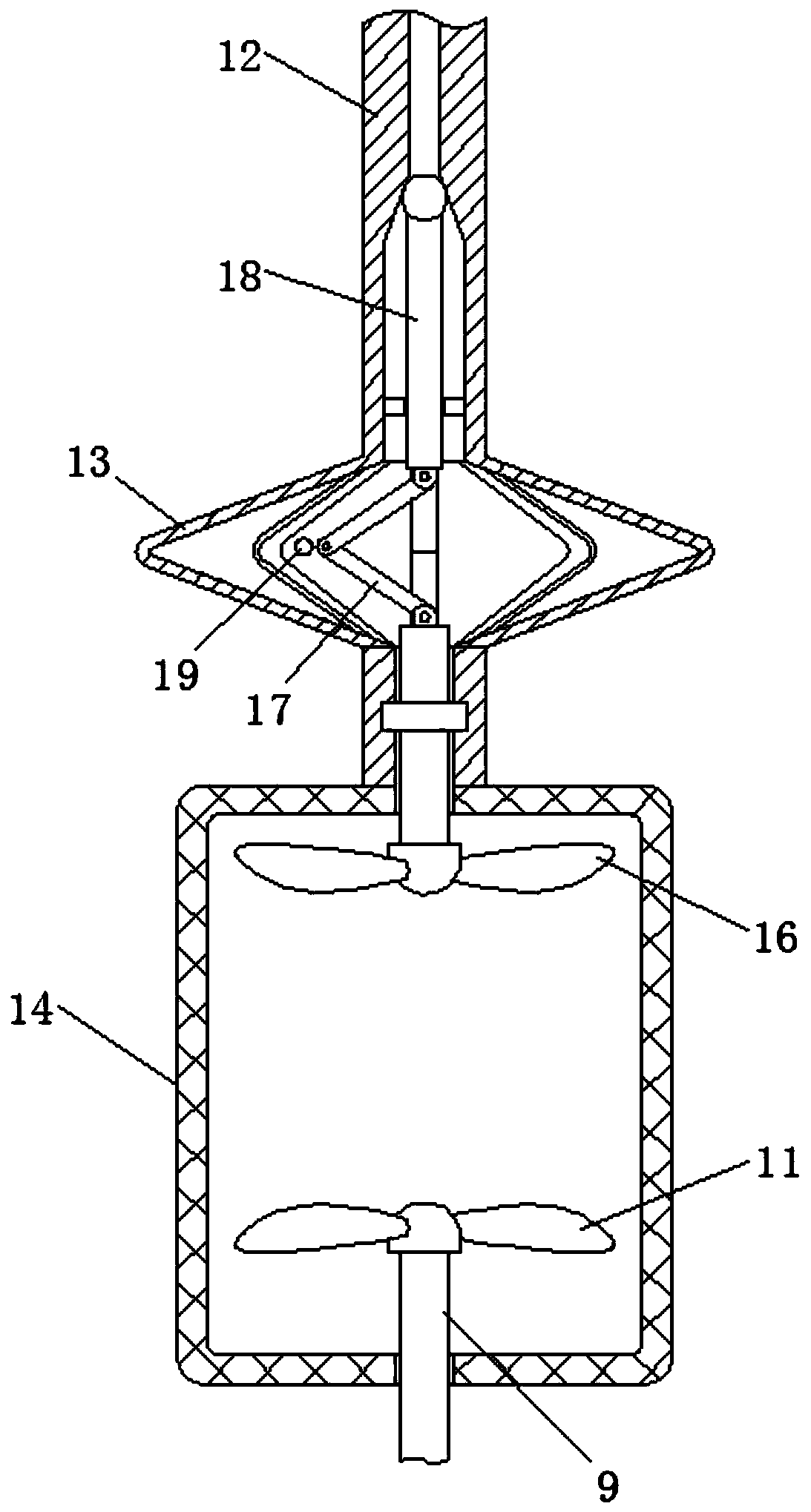

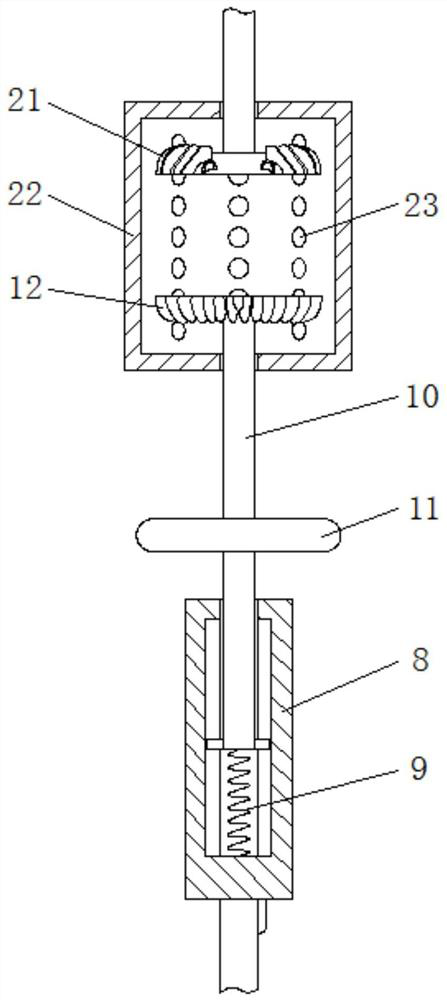

Stirring and neutralizing device for sewage treatment based on hydraulic coupling

InactiveCN111362389AWell mixedEasy to handleShaking/oscillating/vibrating mixersTransportation and packagingGear wheelElectric machinery

The invention provides a stirring and neutralizing device for sewage treatment based on hydraulic coupling, and relates to the technical field of sewage treatment. The stirring and neutralizing devicecomprises a tank body, a base is fixedly mounted at the bottom end of the tank body; the bottom of the tank body is rotationally connected with a first gear; the bottom end of the first gear is in transmission connection with a motor, stirring blades are fixedly installed at the top end of the first gear, a second gear is meshed with the periphery of the first gear, a rotary drum is fixedly installed in the center of the top end of the second gear, and a lifting rod is fixedly connected into the rotary drum through a spring. After a medicament enters the tank body, the medicament can be stirred and then dispersed into the tank body by the stirring and neutralizing device, so that mixing of the medicament and sewage is facilitated, self-adjustment of the dosage of the medicament accordingto the amount of the sewage in the tank body is realized, and the sewage treatment effect is improved.

Owner:李志云

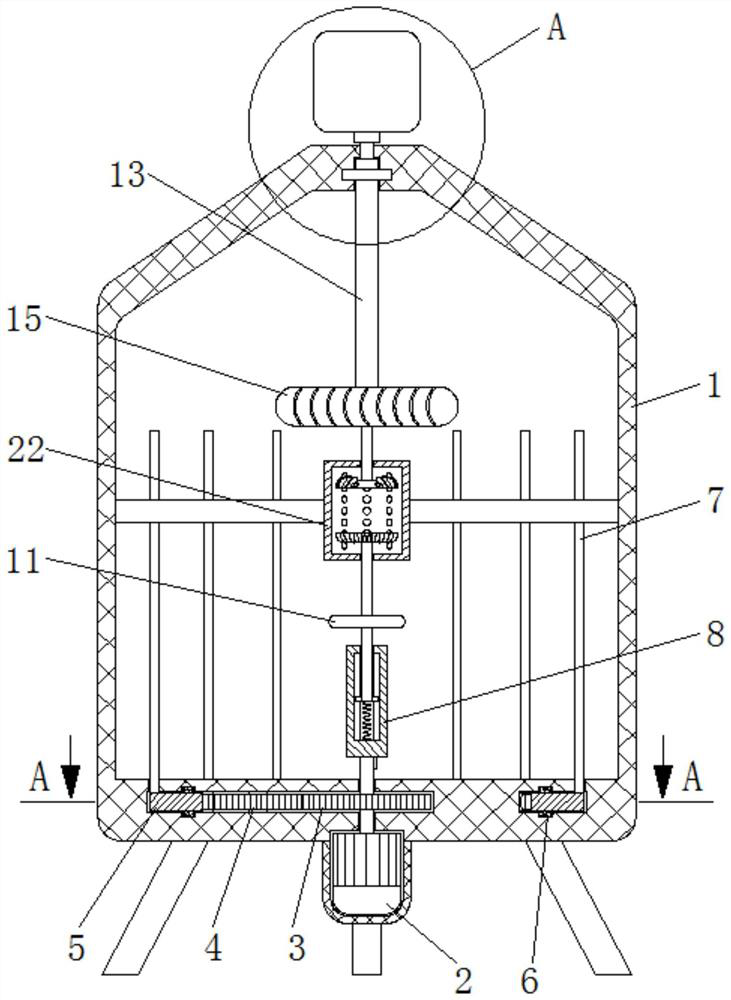

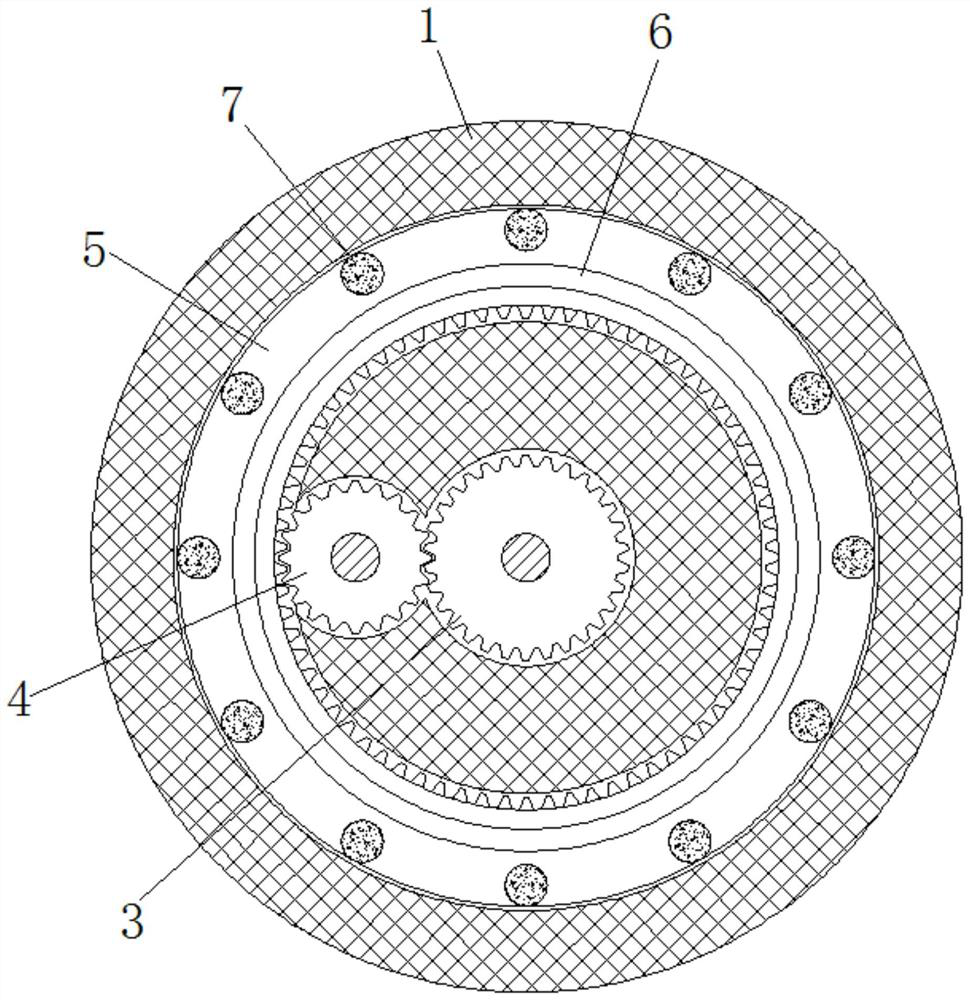

Stirring device for sewage treatment based on hydraulic coupling

ActiveCN111634989AWell mixedEasy to handleWater/sewage treatment by neutralisationSustainable biological treatmentRotational axisGear wheel

The invention provides a stirring device for sewage treatment based on hydraulic coupling, and relates to the technical field of sewage treatment. The stirring device for sewage treatment based on hydraulic coupling comprises a tank body. A motor is fixedly mounted in the center of the bottom of the tank body; a first gear is fixedly installed at the top end of the motor, a second gear is meshed with the left side of the first gear, a gear ring is meshed with the left side of the second gear, limiting rings are fixedly installed at the upper end and the lower end of the gear ring, a stirring rod is fixedly installed at the top end of the gear ring, and a rotating shaft is fixedly installed at the bottom end of the second gear. According to the stirring device for sewage treatment based onhydraulic coupling, the stirring rod at the top end of the gear ring and the stirring blade in the center of the tank body can rotate in opposite directions so that sewage in the tank body is stirredin a crossed manner, mixing of the sewage and chemicals is facilitated, self-adjustment of the outflow amount of the chemicals according to the water level is achieved, and the sewage treatment effectis improved.

Owner:涟源市海川达水务有限公司

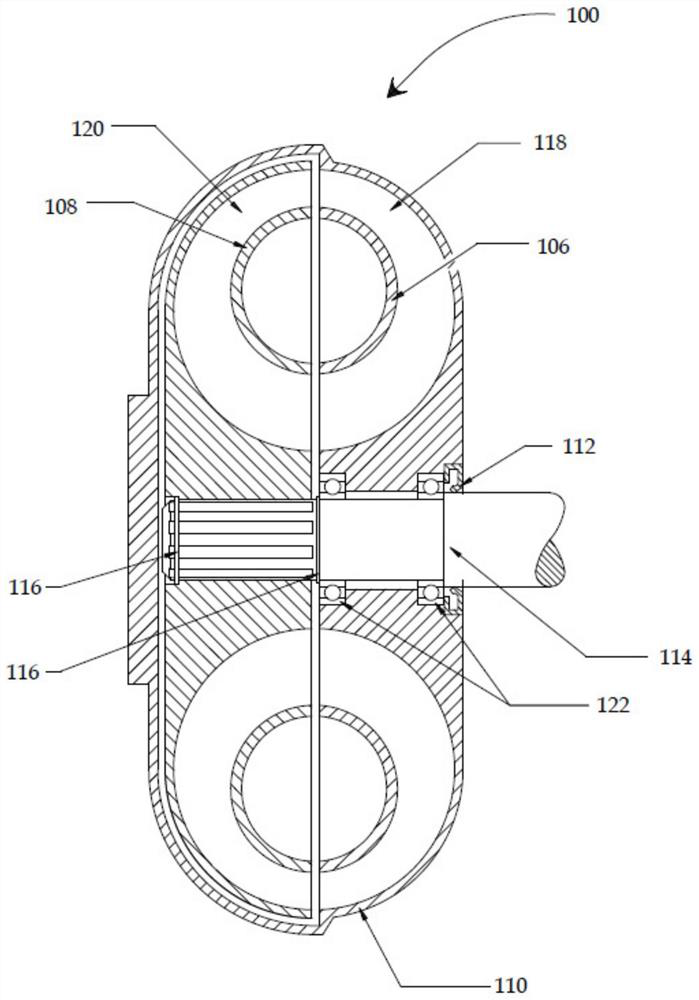

Centrifugal pump

InactiveCN111828338AReduce complexityReduce transmission lossPump componentsFluid removalDrive shaftCoupling

A centrifugal pump for conveying a process fluid is proposed, having a pump unit, a drive unit for driving the pump unit, a pump inlet for receiving the process fluid and a pump outlet for dischargingthe process fluid, wherein the pump unit comprises at least one impeller for conveying the process fluid from the pump inlet to the pump outlet, and a pump shaft, on which each impeller is mounted, wherein the drive unit comprises a drive shaft for driving the pump shaft, and an electric motor for rotating the drive shaft about an axial direction, wherein a plurality of bearings is provided for supporting the pump shaft and the drive shaft, wherein a hydrodynamic coupling having a casing is provided for hydrodynamically coupling the drive shaft to the pump shaft by means of a transmission fluid, and wherein at least one of the plurality of bearings is arranged in the casing of the hydrodynamic coupling.

Owner:SULZER MANAGEMENT AG

Hydraulic coupling transmission device for wind turbine generator and working method of hydraulic coupling transmission device

The invention discloses a hydraulic coupling transmission device for a wind turbine generator and a working method of the hydraulic coupling transmission device, and belongs to the field of logical design of wind turbine generators. The hydraulic coupling transmission device comprises a fan impeller used for starting the wind turbine generator, a small constant-speed-ratio hydraulic coupling, a wind turbine generator electric generator, a coupling auxiliary device, cables and an alternating-current power supply; the fan impeller is mounted in front of the small constant-speed-ratio hydraulic coupling, the wind turbine generator electric generator is mounted behind the small constant-speed-ratio hydraulic coupling, and the fan impeller, the small constant-speed-ratio hydraulic coupling andthe wind turbine generator electric generator are arranged coaxially; and the coupling auxiliary device is arranged in a wind turbine generator cabinet, and used for detecting all temperature measuring point values of the small constant-speed-ratio hydraulic coupling and providing auxiliary services such as an oil tank, cooling and purification for the small constant-speed-ratio hydraulic coupling, and the coupling auxiliary device is connected with the alternating-current power supply through the corresponding cable. The hydraulic coupling transmission device is perfect in structure, compactin system, high in practicality and suitable for use in the wind power industry, and has operability and wide applicability.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Process fluid lubricated pump

InactiveUS20200340480A1Reduced dimensionPositive displacement pump componentsEngine fuctionsImpellerDrive shaft

A process fluid lubricated pump for conveying a process fluid, includes a common housing, a pump unit arranged in the common housing, a drive unit arranged in the common housing, and a hydrodynamic coupling. The common housing includes a pump inlet and a pump outlet for the process fluid. The pump unit includes at least one impeller configured to convey the process fluid from the pump inlet to the pump outlet, and a pump shaft, on which the impeller is mounted. The drive unit includes a drive shaft configured to drive the pump shaft, and an electric motor configured to rotate the drive shaft about an axial direction. The hydrodynamic coupling is configured to hydrodynamically couple the drive shaft to the pump shaft by a transmission fluid, and is configured to receive the process fluid as the transmission fluid.

Owner:SULZER MANAGEMENT AG

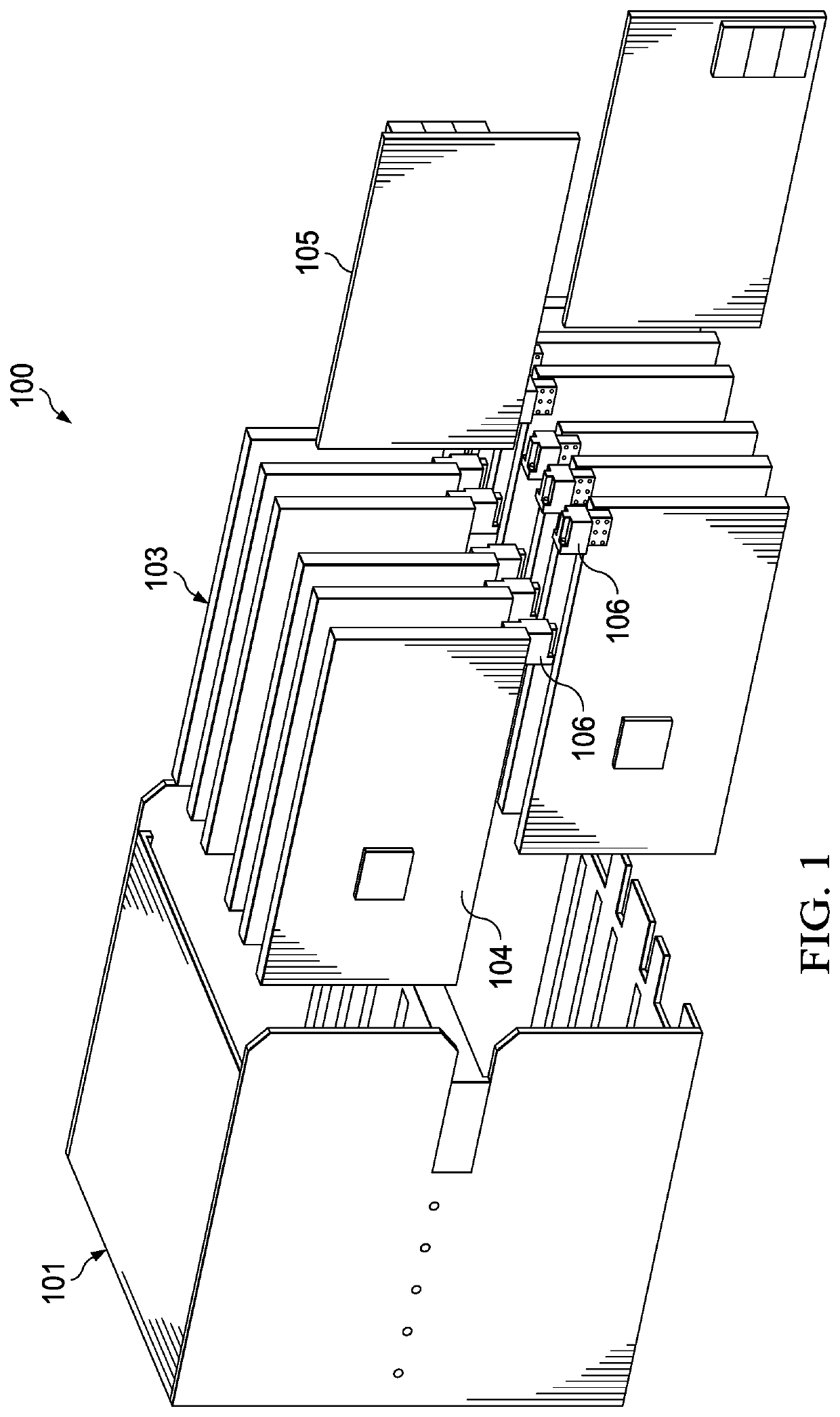

Multi-purpose coolant interface

ActiveUS20200029469A1Increase and maintain compressionWave based measurement systemsModular arraysFluid couplingMechanical stability

A coolant interface includes a line replaceable unit (LRU) inserted into a slot within a modular assembly such as a chassis for an electronics assembly. Quick disconnect fluid coupling fittings on the LRU mate with counterpart fittings on a fluid distribution manifold within the chassis when the LRU is inserted into the slot. A seal surrounding the quick disconnect fluid coupling fittings on a flat surface abutting a counterpart surface on the fluid distribution manifold when the LRU is inserted into the slot compresses the seal against the counterpart surface. Alignment pin(s) projecting from the flat surface and received by corresponding guide holes within the counterpart surface, and captive hardware provides pressure between the flat surface and the counterpart surface to increase and maintain compression of the seal. The alignment pins and captive hardware are arranged to increase mechanical stability of the connection.

Owner:RAYTHEON CO

A Prediction Method of Saturated/Unsaturated Permeability Coefficient Based on Microscopic Pore Channels

ActiveCN107063967BFit closelySimple calculationPermeability/surface area analysisPredictive methodsOsmotic coefficient

The invention relates to a micropore channel-based saturated / unsaturated osmotic coefficient forecasting method, which comprises the following steps: on the basis of a micro-connected channel seepage model and the capillary theory, building a model for forecasting a saturated / unsaturated osmotic coefficient through soil-water characteristic curves; obtaining the soil-water characteristic curve and a saturated osmotic coefficient of soil through a pressure plate apparatus and a varying head test; calculating a comprehensive osmotic ratio constant kc by using the model of the saturated osmotic coefficient; performing n equal division according to the comprehensive osmotic ratio constant kc of a certain type of soil and the actually measured soil-water characteristic curve, and calculating a saturated osmotic coefficient ks and an unsaturated relative osmotic coefficient kr of the type of soil by using the relevant model; multiplying the saturated osmotic coefficient ks and the unsaturated relative osmotic coefficient kr, thus obtaining an unsaturated osmotic coefficient kw. From a microscopic view, the method disclosed by the invention has an important significance for revealing an internal mechanism for controlling the size of an osmotic coefficient of the soil, analyzing seepage of unsaturated soil and researching hydromechanical coupling.

Owner:HUBEI UNIV OF TECH

Hydrodynamic coupling with a speed protection mechanism and turbocompound system

The invention relates to a hydrodynamic coupling, in particular for a turbocompound system, comprising: an impeller; and a turbine wheel, which together with the impeller forms a working chamber that can be filled with a working medium. The inventive dynamic coupling is characterised in that it is equipped with a mechanical locking device for connecting the impeller and turbine wheel in a rotationally fixed manner, said device being linked to a region of the coupling that conducts the working medium in such a way that it closes if a predetermined fill level has not been reached.

Owner:VOITH TURBO GMBH & CO KG

Process fluid lubricated pump

A process fluid lubricated pump for conveying a process fluid is proposed, having a common housing, a pump unit arranged in the common housing, and a drive unit arranged in the common housing, whereinthe common housing comprises a pump inlet and a pump outlet for the process fluid, wherein the pump unit comprises at least one impeller for conveying the process fluid from the pump inlet to the pump outlet, and a pump shaft, on which each impeller is mounted, wherein the drive unit comprises a drive shaft for driving the pump shaft, and an electric motor for rotating the drive shaft about an axial direction, and wherein a hydrodynamic coupling is provided for hydrodynamically coupling the drive shaft to the pump shaft by means of a transmission fluid. The hydrodynamic coupling is configuredto receive the process fluid as the transmission fluid.

Owner:SULZER MANAGEMENT AG

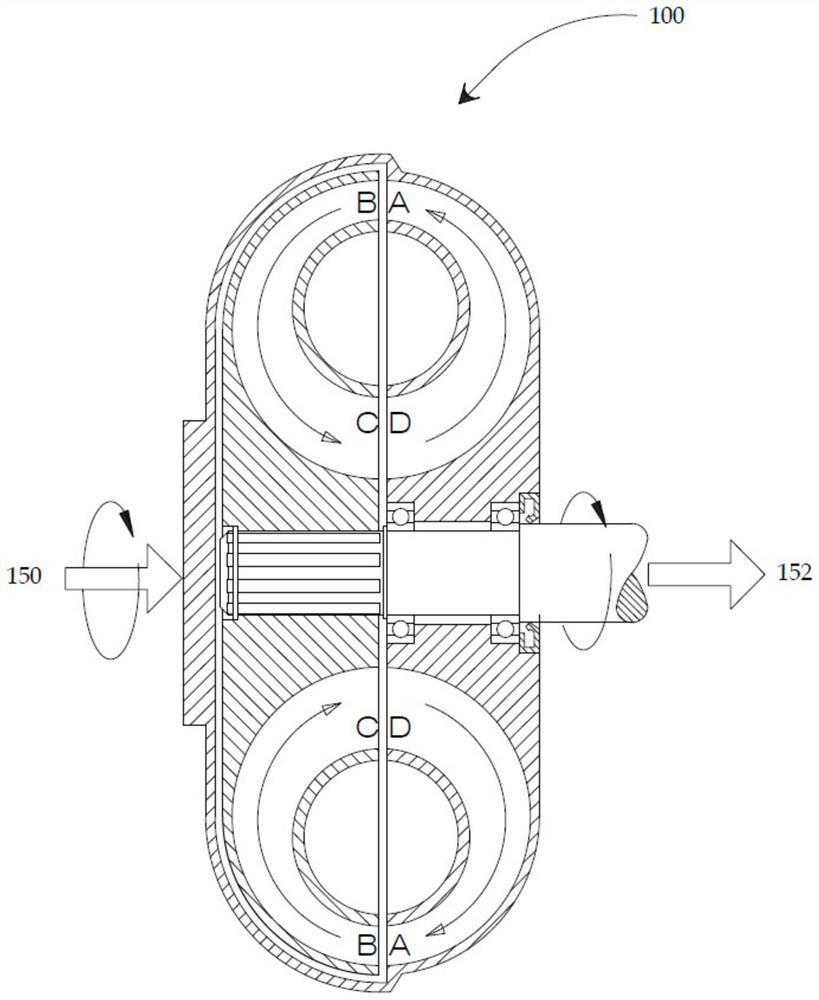

Hydraulic coupler for continuously variable transmission

The invention discloses a hydraulic coupler for a continuously variable transmission and a coupling method. The hydraulic coupler includes a pump having a first semi-torus and a turbine having a second semi-torus. The first and second semi-toroidal bodies together form a toroidal body. A first set of fluid guide vanes is disposed radially at the first semicircular body. A first set of blades extends from the rim of the first semi-torus and terminates at a region proximate the hub of the first semi-torus. A second set of fluid guide vanes is disposed radially at the second semicircular body. A second set of blades extends from the rim of the second semi-torus and terminates at a region proximate the hub of the second semi-torus. The hydrodynamic coupling device is configured to decouple the negative coupling effect and provide a continuously variable transmission.

Owner:沙达蓬·苏普里查科

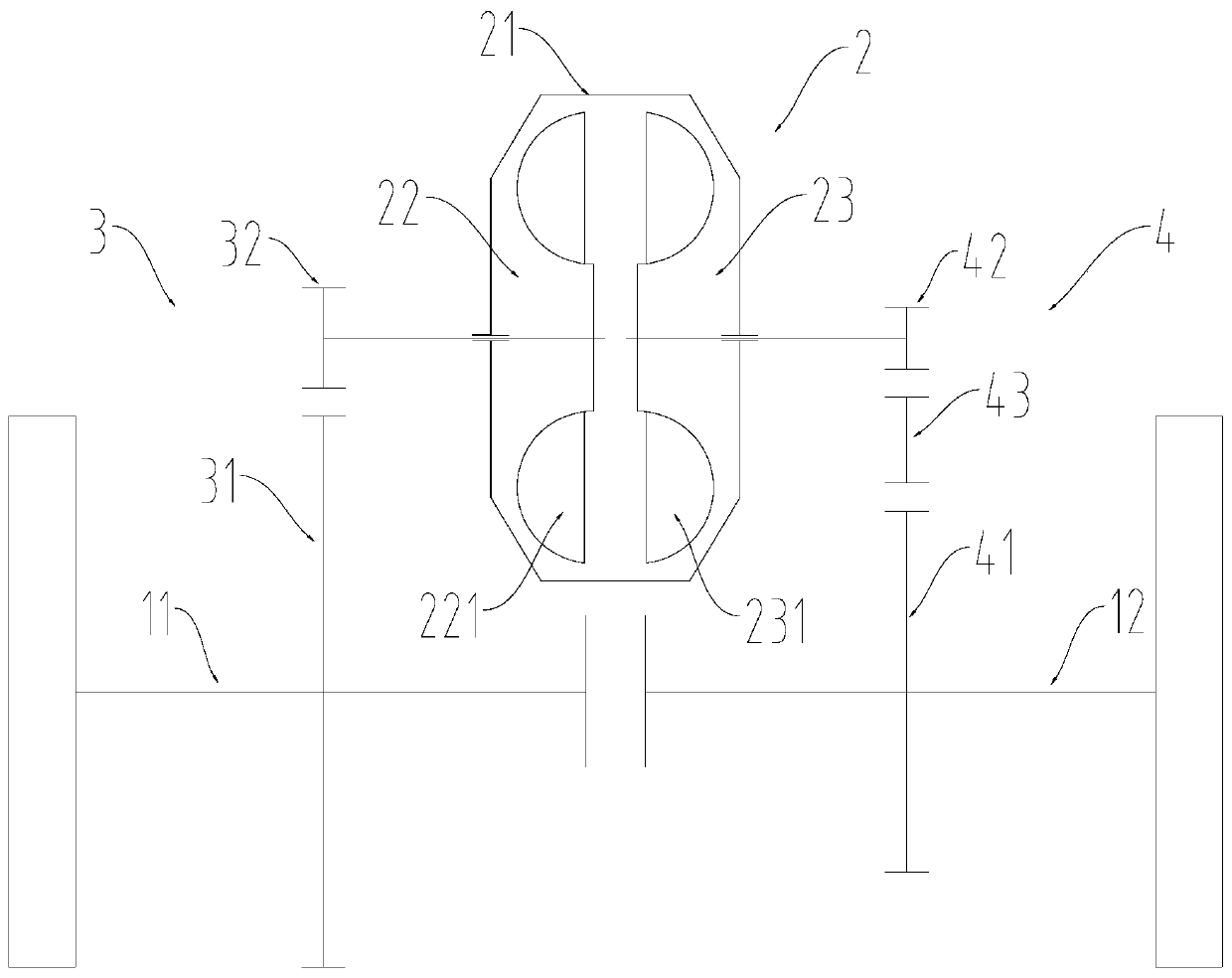

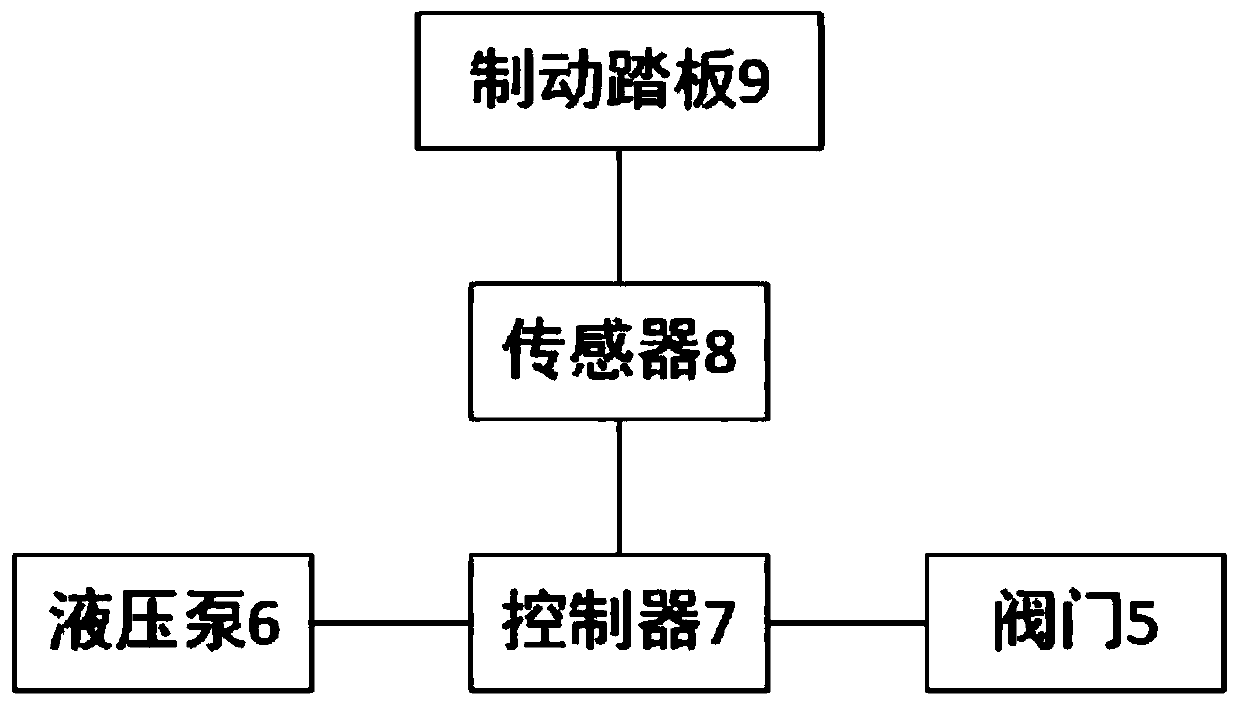

Brake device, brake system and vehicle

The invention relates to a brake device, a brake system and a vehicle. The brake device comprises a hydraulic coupling structure used for being arranged between a first half shaft and a second half shaft of an axle, and the hydraulic coupling structure comprises: a shell provided with a liquid hole for brake liquid to flow in or flow out; a first turbine which is arranged in the shell and can be in transmission connection with the first half shaft through a first gear train, wherein the first turbine is provided with first blades; a second turbine, wherein the second turbine and the first turbine are oppositely arranged in the shell, the second turbine can be in transmission connection with the second half shaft through a second gear train, the second turbine is provided with second blades, and the first gear train and the second gear train are constructed in the mode that when the first half shaft and the second half shaft rotate in the same direction, the rotation direction of the first turbine and the rotation direction of the second turbine are opposite. By means of the technical scheme, the brake device can solve the technical problem that the brake efficiency is low due to the fact that the vehicle brake torque is large.

Owner:BEIQI FOTON MOTOR CO LTD

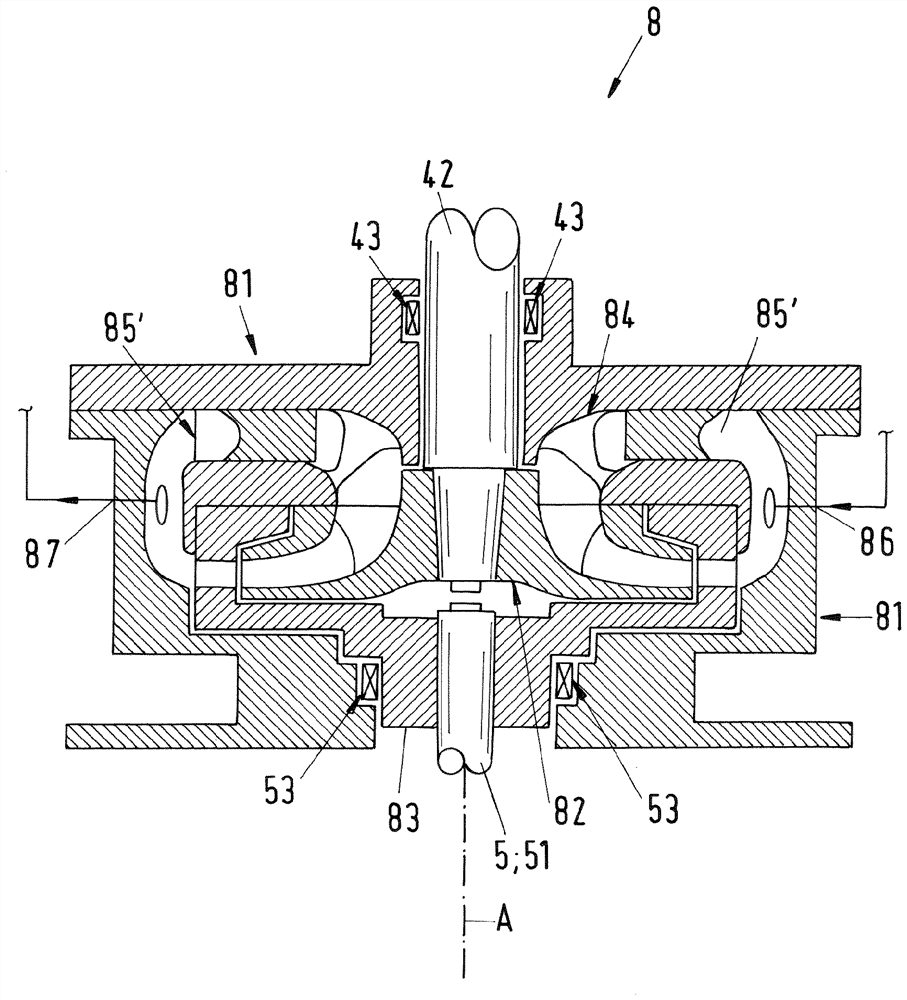

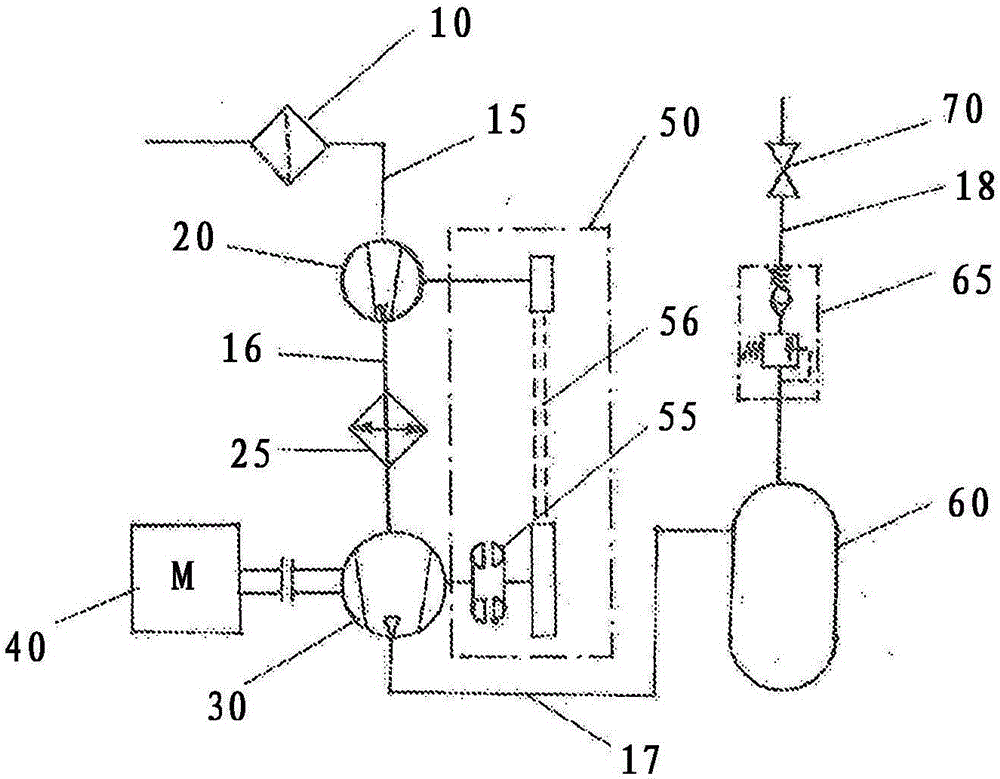

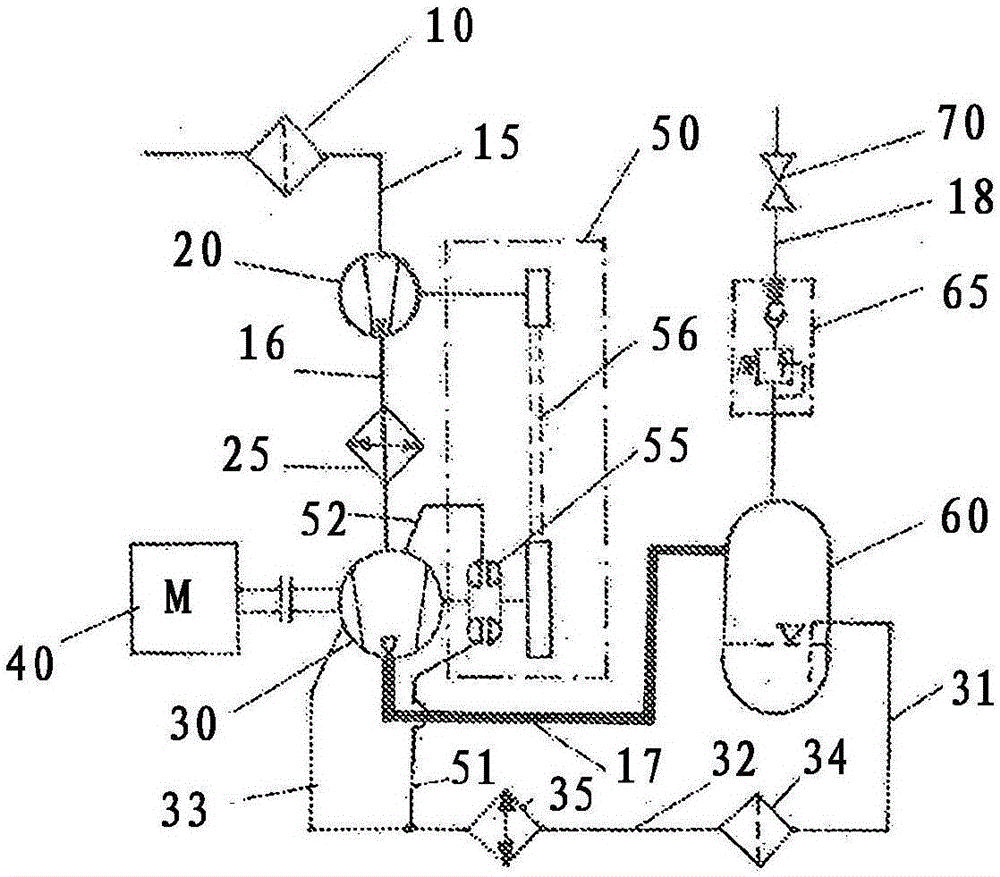

Multistage compressor system with hydrodynamic fluid coupling

InactiveCN106460844ASmall structure sizeAdditional costs are smallRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsFluid couplingGas compressor

A compressor system for producing a compressed gas, more particularly air, comprising at least one main compressor (30) which is supplied with pre-compressed gas with the aid of a pre-compressor (20), wherein the at least one main compressor (30) and also the at least one pre-compressor (20) are driven by a shared drive motor (40) or by separate drives, and at least one pre-compressor (20) is linked to a fluid coupling (55) that changes the drive speed of the pre-compressor (20).

Owner:哈拉尔德文策尔

Hydrodynamic clutch

The invention relates to a hydraulic coupling, which has a primary wheel and a secondary wheel, the primary wheel and the secondary wheel jointly form a torus-shaped working chamber, the primary wheel is arranged on a drive shaft Or integrally formed with the drive shaft, wherein at least one inlet channel for feeding the working medium into the working chamber and at least one outlet channel for simultaneously discharging the working medium from the working chamber are formed in the drive shaft.

Owner:VOITH TURBO GMBH & CO KG

Hydrodynamic coupling arrangement

A hydrodynamic coupling arrangement has a housing connected to pressure medium lines for conducting pressure medium into or out of a pressure space sealed by a piston of a clutch device relative to a toroidal space of a hydrodynamic circuit provided in the housing. A rotatable area is provided for axially displaceably receiving a radially inner piston hub of the piston of the clutch device, and at least one through-opening which is rotatable relative to the housing is provided in a through-opening area for producing at least one flow connection between at least one pressure medium line and the pressure space. The receiving area and the through-opening area are in rotational communication with a retarding device influencing a flow of pressure medium in the pressure space, this flow of pressure medium arriving in the pressure space after passing through the through-opening area.

Owner:ZF FRIEDRICHSHAFEN AG

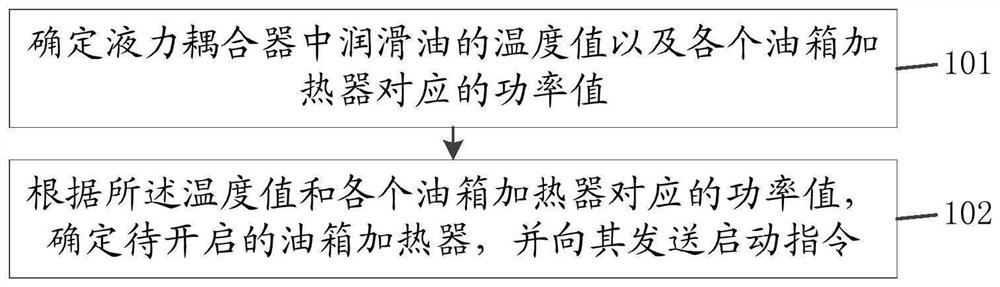

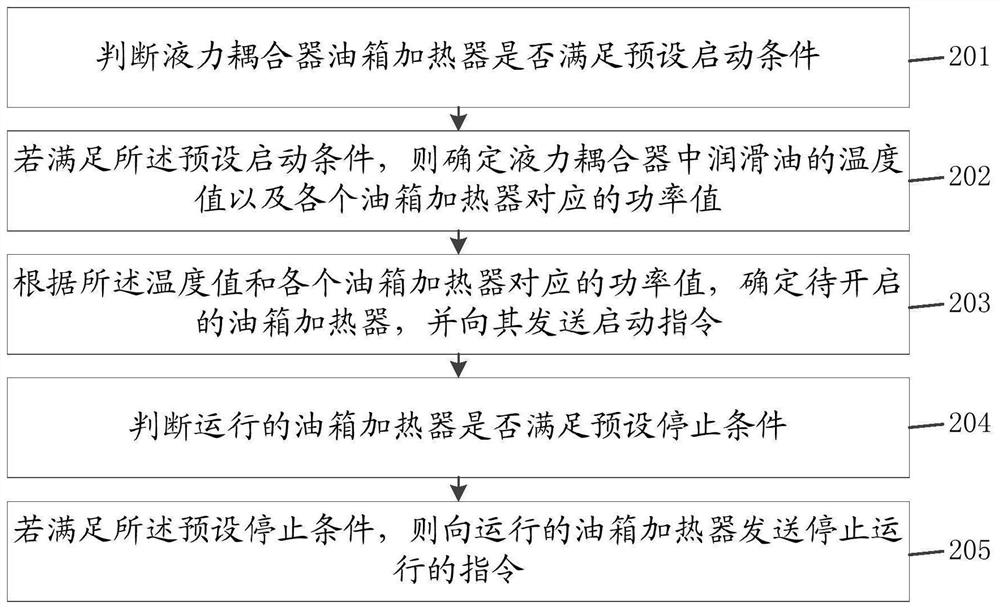

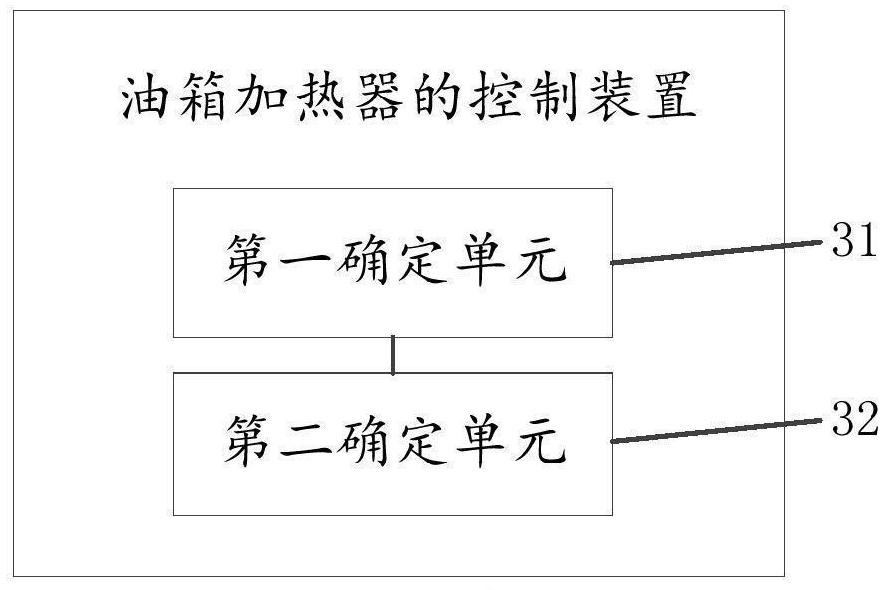

Fuel tank heater control method and device

The invention discloses a control method and device for a fuel tank heater, and relates to the technical field of hydraulic couplers. The main purpose is to effectively control the fuel tank heater, improve the control efficiency of the fuel tank heater, and reduce the work of operators at the same time quantity, saving labor costs. The method includes: determining the temperature value of the lubricating oil in the hydraulic coupling and the corresponding power value of each fuel tank heater; determining the fuel tank heater to be turned on according to the temperature value and the corresponding power value of each fuel tank heater, and sending It sends the start command book. The invention is applicable to the control of fuel tank heaters.

Owner:SHENYANG BLOWER WORKS GRP AUTOMATIC CONTROL SYST ENG +1

Hydrophone housing

ActiveUS10677945B2Stress minimizationLow loss transfer of pressure energySubsonic/sonic/ultrasonic wave measurementSeismic signal receiversHydrophoneEngineering

The invention relates to a hydrophone housing. The housing comprises an outer casing with an exterior shape being in close contact with sediment when buried therein and having a deflectable wall part. Solid material partly fills the casing to define an outer chamber behind the deflectable wall part, a cavity shaped so that an inner chamber is defined immediately surrounding a hydrophone sensing element held therein, and a first duct for liquid flow communication between the outer chamber and the cavity or an internal volume of the hydrophone sensing element. Thereby, a hydraulic coupling is provided so that an acoustic pressure causing small radial displacements of outer surface of the housing will, via liquid in the first duct, cause large radial displacements of the hydrophone sensitive element. The area of the deflectable wall part is much larger than the area of the sensitive element so that only small displacements of the housing are required to cause large displacements at the hydrophone sensing element.

Owner:OPTOPLAN

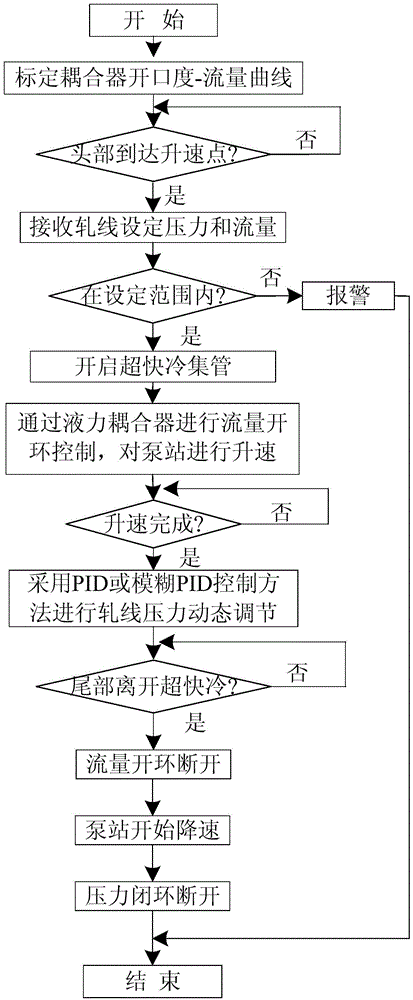

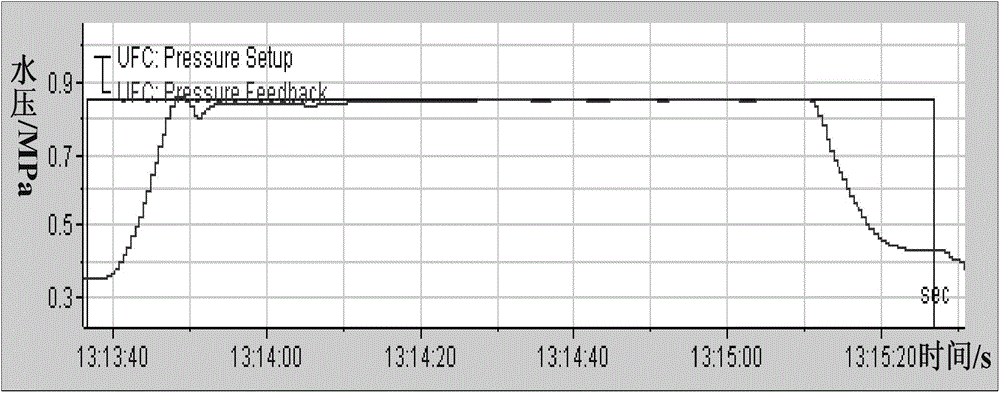

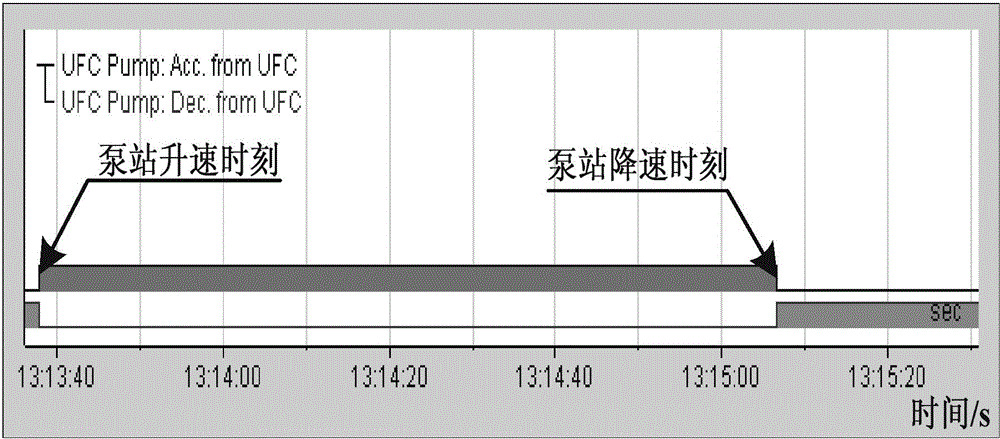

Water supply control method for ultra-rapid cooling system of hot continuous rolling line

ActiveCN103605390BSolve stressFix stability issuesSimultaneous control of multiple variablesFluid couplingLoop control

A water supply control method for an ultra-rapid cooling system of a hot continuous rolling line belongs to the technical field of hot strip rolling. Including: Step 1: Calibrate the hydraulic coupling opening degree-pumping station flow curve; Step 2: Determine whether the strip head has reached the speed increase point. If so, the rolling line will send the set pressure and total flow rate to the pumping station. Perform step three; if not, perform step two; step three: Determine whether the set pressure and set total flow rate sent by the rolling line to the pump station meet the set range. If so, open the ultra-fast cold header and the pump station will start the flow rate. Ring control and increase the speed, perform step four; if not, alarm; Step four: Determine whether the speed increase process is completed, if so, use the fuzzy PID control method to dynamically adjust the rolling line pressure; if not, perform step four; Step Five: Determine whether the tail end of the strip leaves the ultra-fast cooling zone. If so, the flow open-loop control is disconnected, the pump station is slowed down to the base speed, and the rolling line pressure dynamic adjustment closed loop is disconnected; if not, step 5 is performed.

Owner:NORTHEASTERN UNIV LIAONING

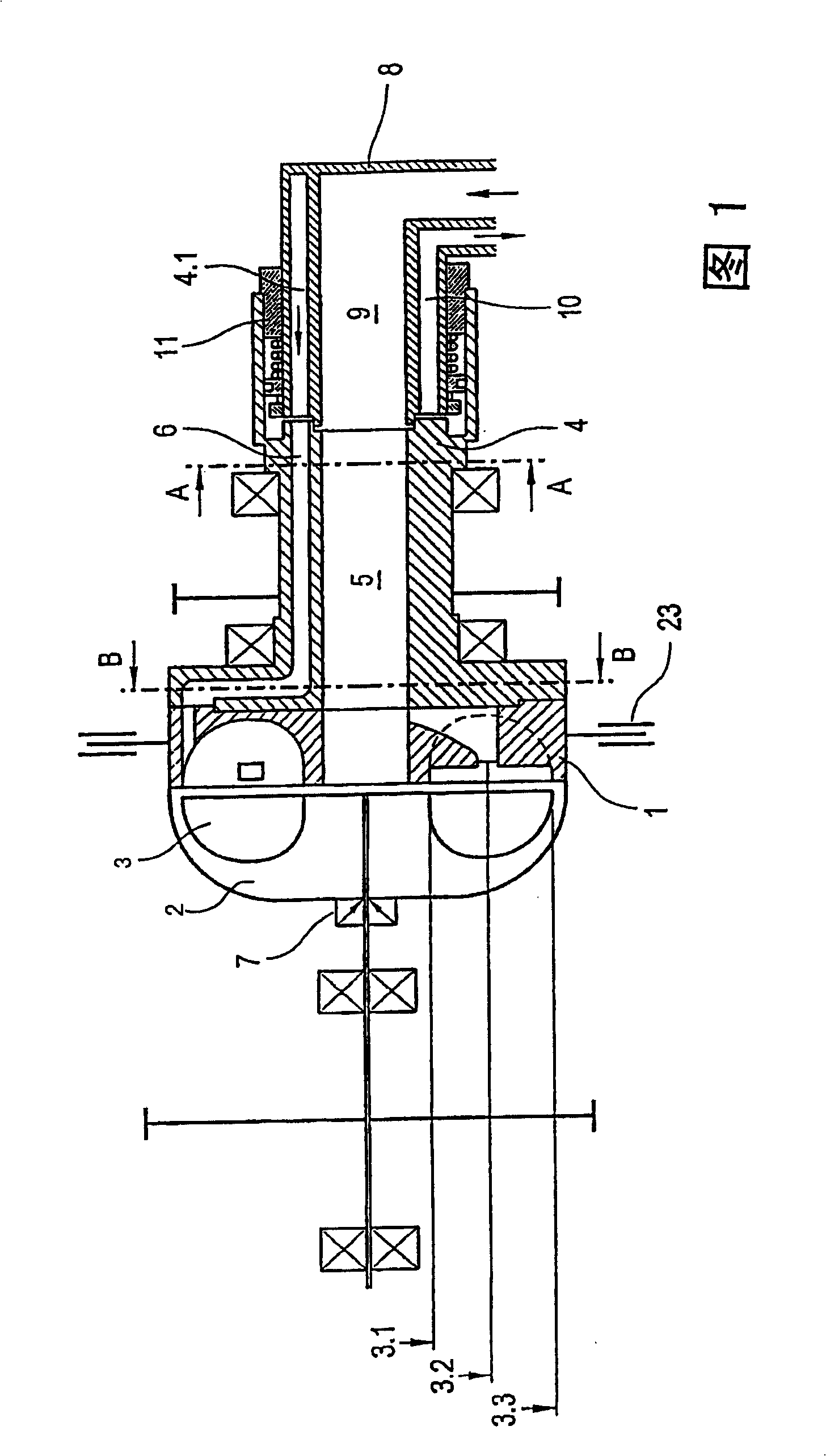

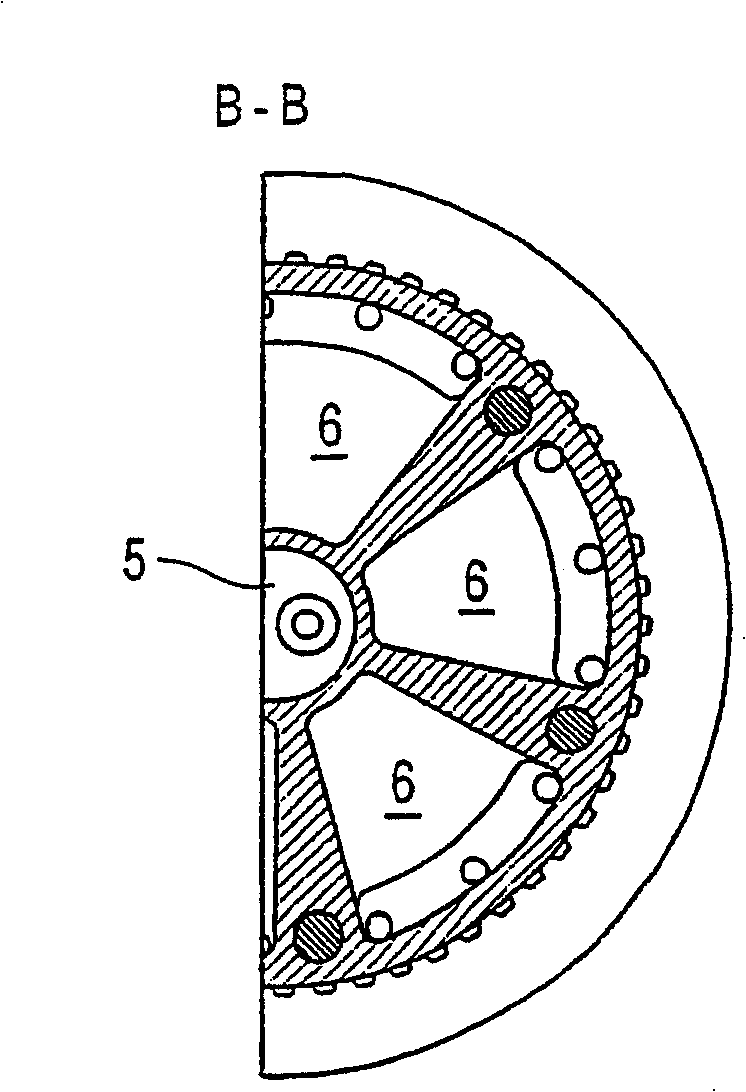

Hydrodynamic coupling

A filling-controlled hydrodynamic coupling comprises a pump wheel and a turbine wheel which delimit a working chamber and which can be mechanically coupled to one another by means of a hydraulic fluid; a direct circuit, which connects a hydraulic outlet to a hydraulic inlet of the working chamber; a pump device, which is arranged hydraulically between a fluid source and the direct circuit; and a lubrication line, which leads from the pump device to a lubrication point of the coupling. Here, the pump device is designed to convey fluid in a first conveying direction from the fluid source into the working chamber and into the lubrication line or in a second conveying direction from the working chamber to the fluid source.

Owner:VOITH PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com