Method for regulating the maximum speed of a working machine and associated hydrodynamic coupling

A technology of hydraulic coupling and working machinery, applied in the direction of clutches, clutches, mechanical equipment, etc., can solve the problem of reducing the maximum speed of air compressors, the structure of hydraulic shift couplers is complex, and it is not suitable for monitoring the speed of working machinery, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

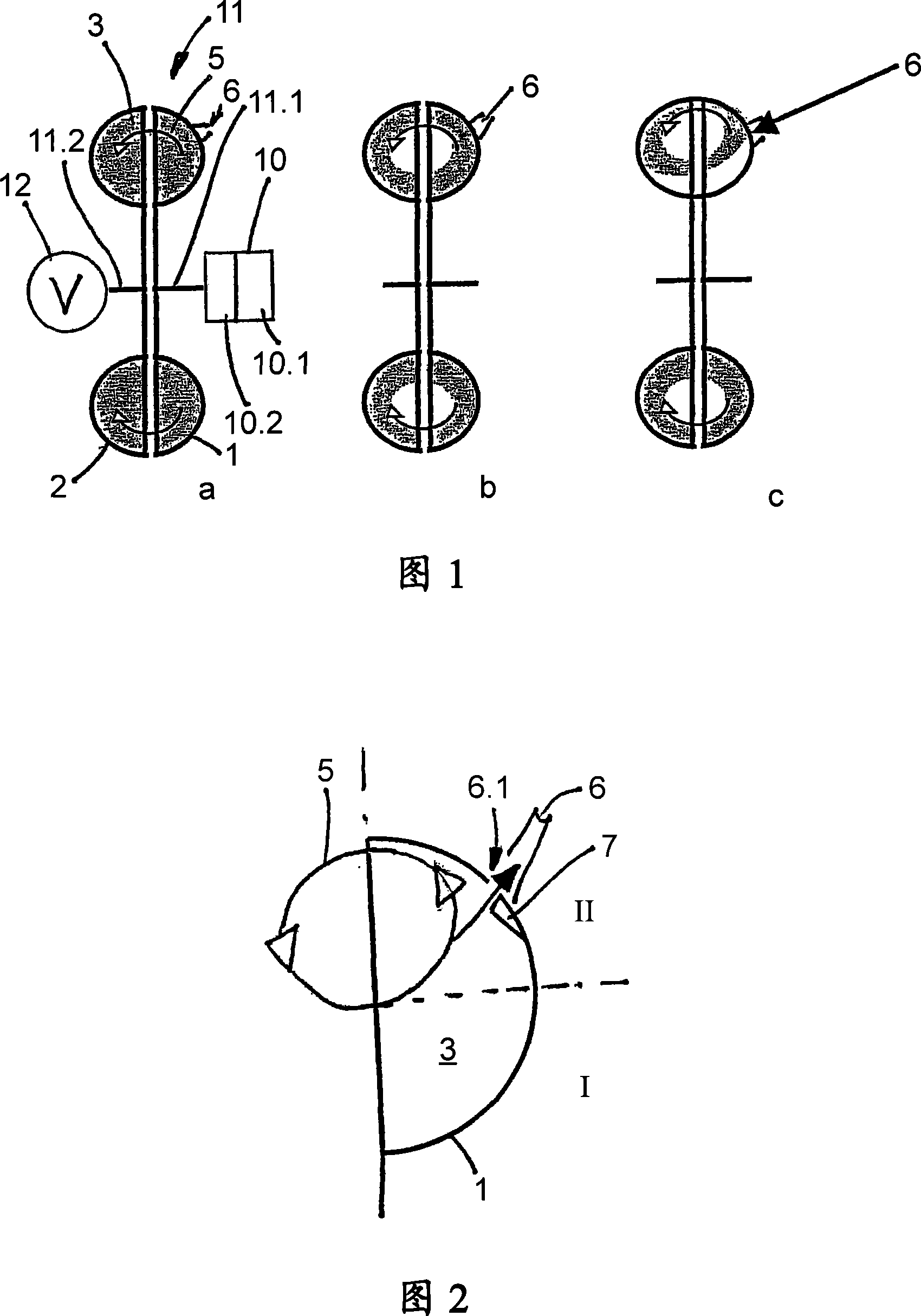

[0021] FIG. 1 schematically shows a fluid coupling 11 , which is inserted into a drive connection between an engine 10 and a working machine 12 . The engine 10 here comprises an internal combustion engine 10.1 having a transmission 10.2 connected thereto. The output shaft of the transmission 10.2 is connected to the input 11.1, which includes the pump wheel 1 of the fluid coupling 11. The output 11.2 of the hydrodynamic coupling including the turbine 2 is connected to a working machine 12, which is an air compressor. Of course, other transmissions or transmissions can be provided in the connection between the engine 10 or the transmission 10.2 and the pump wheel 1, respectively, and in the connection between the turbine 2 and the working machine 12, in order to set the desired rotational speed Compare. It is also possible to have an additional transmission or transmission only on one side of the coupling 11 .

[0022] FIG. 1 a schematically shows the state of the hydrodynam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com