Centrifugal pump

A technology for centrifugal pumps and pump shafts, applied in the field of centrifugal pumps, which can solve the problems of high viscosity loss and inability to allow economical and efficient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

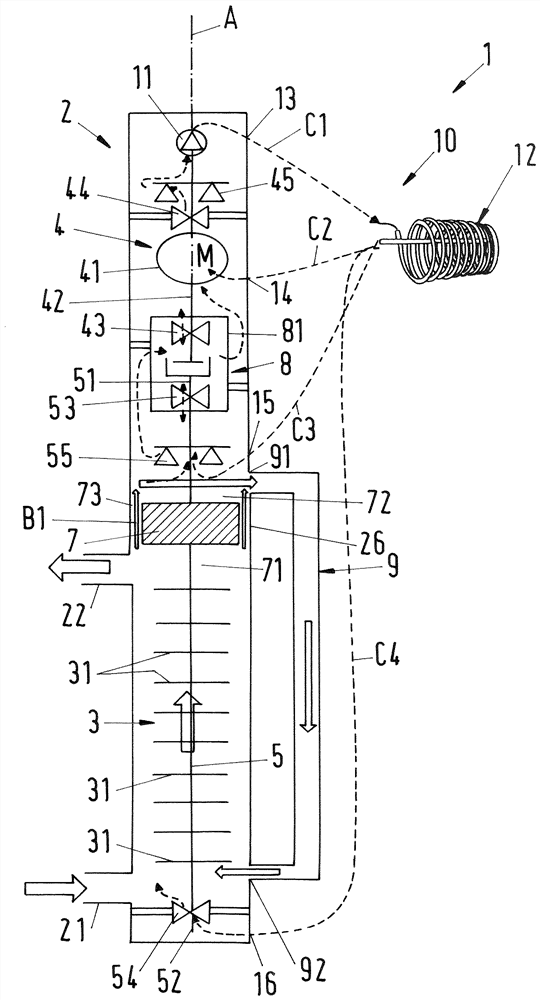

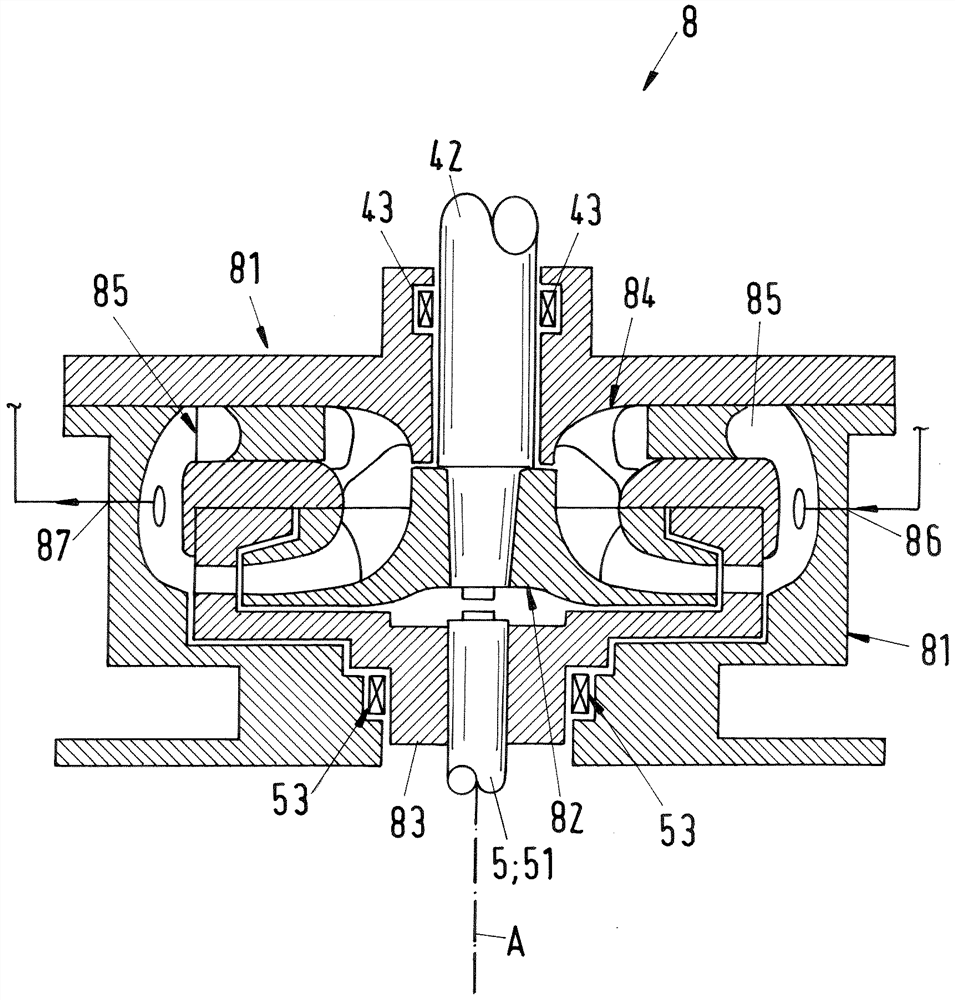

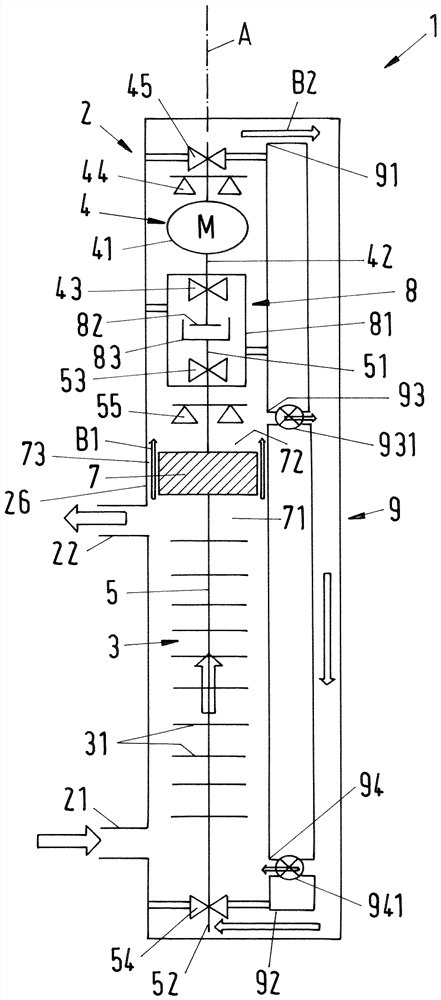

[0041] figure 1 A schematic cross-sectional view of a first embodiment of a centrifugal pump according to the invention is shown, which pump is designated in its entirety by the reference number 1 . For example, the pump 1 is designed as a process fluid lubrication pump for conveying process fluids and has a common housing 2 , a pump unit 3 and a drive unit 4 . Both the pump unit 3 and the drive unit 4 are arranged in a common housing 2 . The common housing 2 is designed as a pressure housing which can withstand the pressure generated by the pump 1 and the pressure exerted on the pump 1 by the environment. The common housing 2 may comprise several housing parts, eg a pump housing and a driver housing, which are connected to each other to form a common housing 2 surrounding the pump unit 3 and the drive unit 4 . The common housing 2 is configured as an airtight pressure housing which prevents any leakage to the external environment.

[0042] In the following description refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com