Hydrodynamic coupling

A hydraulic coupler and coupler technology, applied in the direction of clutch, clutch, fluid clutch, etc., can solve the problems of reducing the availability or durability of the coupler, the drain valve and its driving control consumption, etc., and achieve the reduction of parameters or characteristics. Risks, avoidance of connection or wiring costs, the effect of simplifying the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

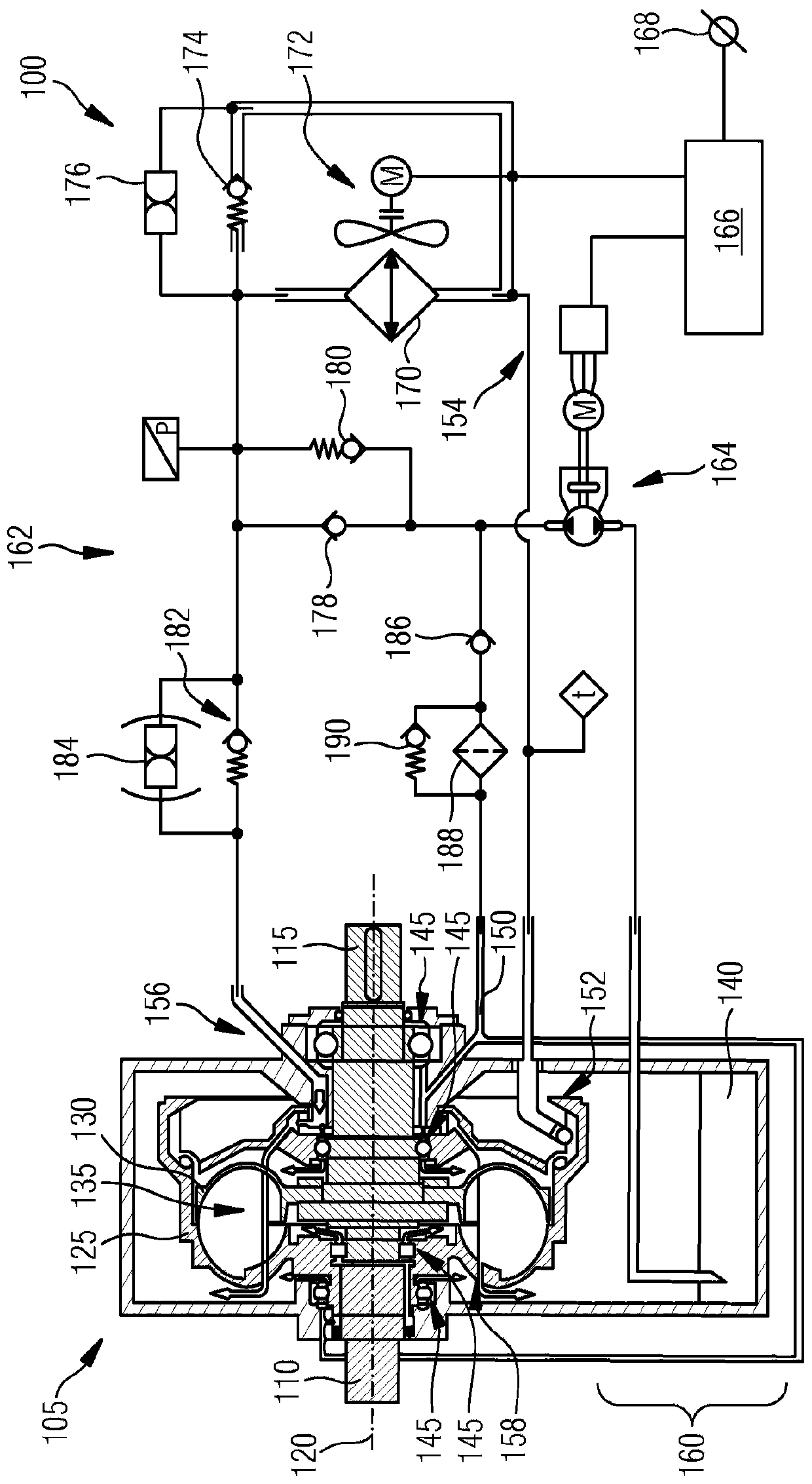

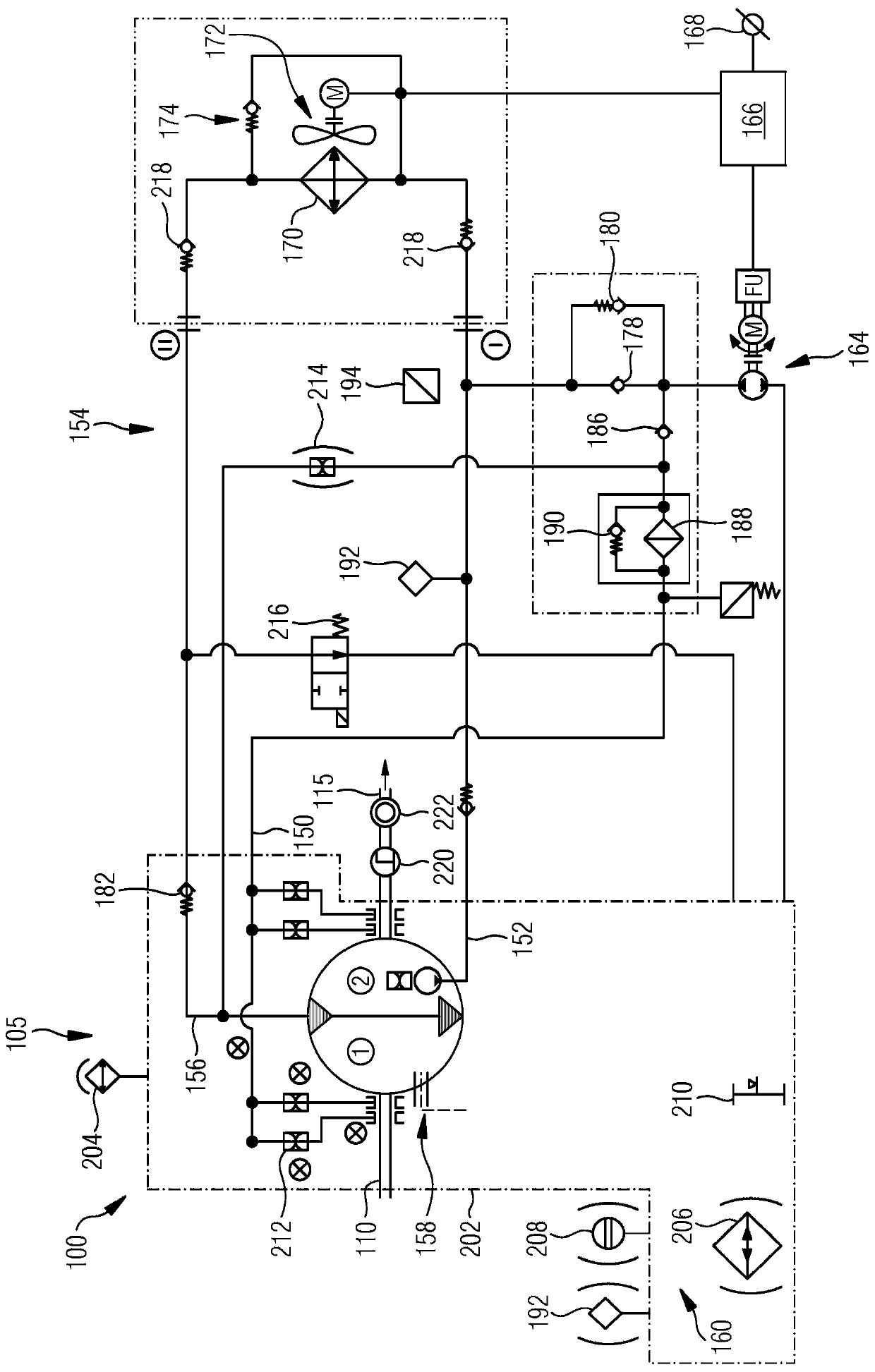

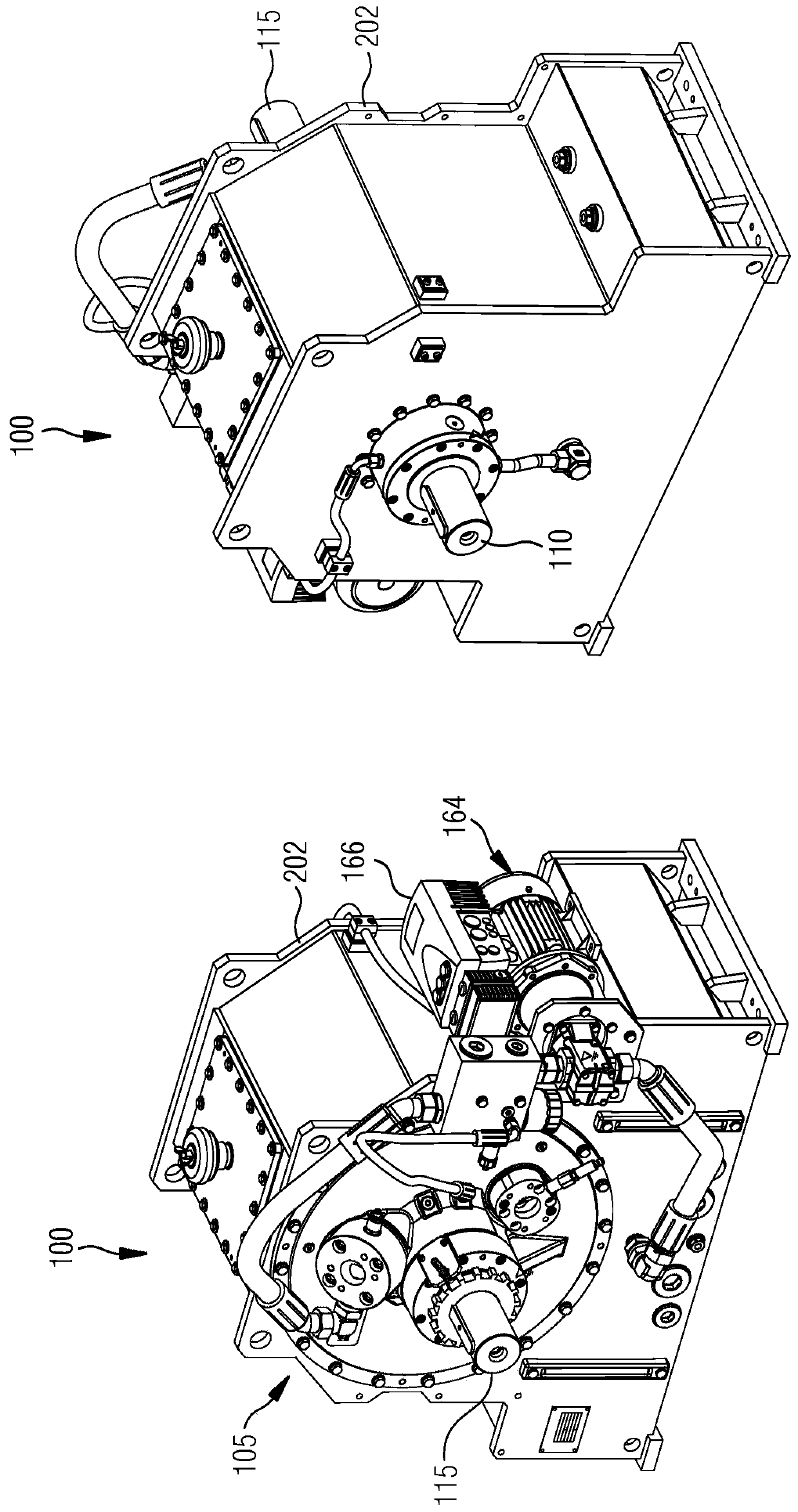

[0032] figure 1 A schematic diagram of a coupling system 100 with a fill-controlled fluid coupling 105 is shown. The coupling 105 is designed for controllably transmitting a rotational movement between an input side 110 and an output side 115 , which are mounted rotatably relative to each other about a common axis of rotation 120 . The coupling 105 includes a pump wheel 125 connected to the input side 110 and a turbine wheel 130 connected to the output side 115 . The pump wheel 125 and the turbine wheel 130 form a working chamber 135 in which a fluid 140 can be accommodated in order to hydraulically couple the turbine wheel 130 to the pump wheel 125 . In this case, the degree of coupling is related to the quantity of fluid 140 contained in the working chamber 135 . Pump wheel 125 and turbine wheel 130 are generally rotatably mounted by means of bearings 145 . For supplying the bearing 145 with fluid 140 a lubrication line 150 is provided. Fluid 140 may include aqueous or o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com