Fuel tank heater control method and device

A heater and fuel tank technology, applied in the direction of engine lubrication, lubricating parts, mechanical equipment, etc., can solve the problems of wasting labor costs, increasing the workload of operators, unable to effectively control the fuel tank heater, etc., to ensure safe production and The effect of stable operation, improving control efficiency and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0025] As the background art, at present, the start and stop of the fuel tank heater is usually controlled by manual operation. However, this method of artificially controlling the fuel tank heater cannot accurately and quickly determine the start or stop conditions of the fuel tank heater, resulting in the inability to effectively control the fuel tank heater, affecting the stable operation of the liquid coupler and heating the fuel tank The control efficiency of the device is low. In addition, this method increases the workload of the operator and wastes a lot of labor costs.

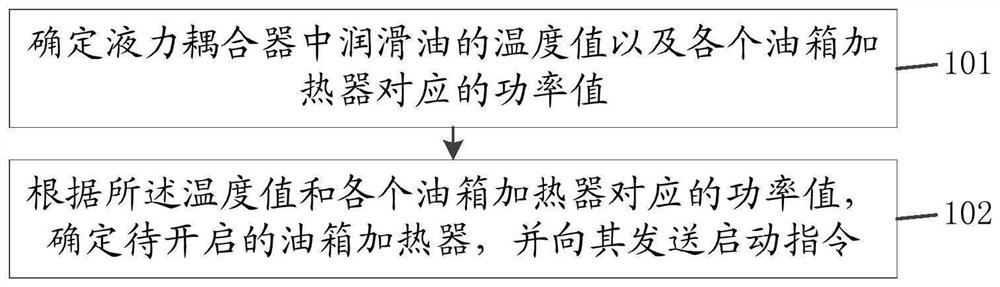

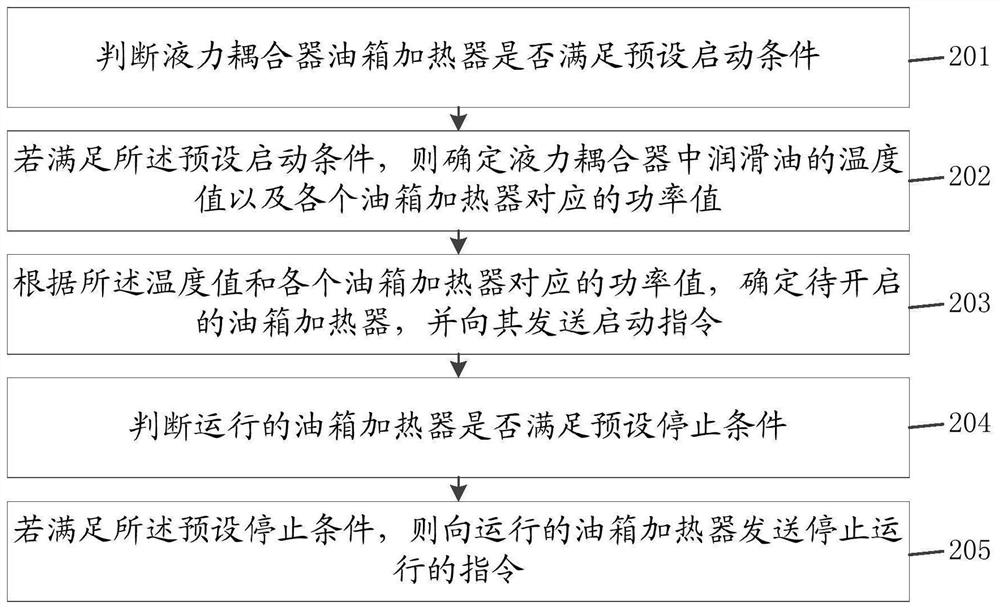

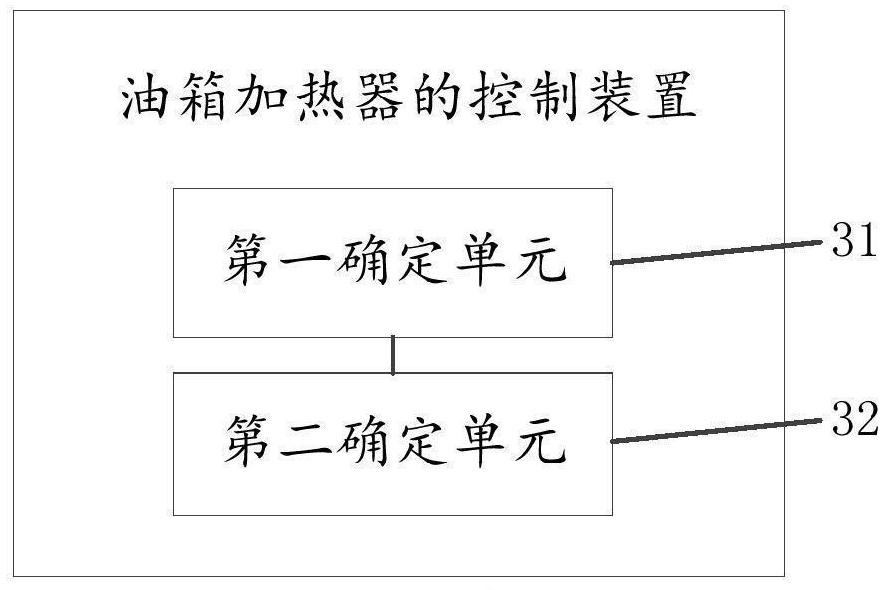

[0026] In order to solve the above problems, an embodiment of the present invention provides a control method for a fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com