Cooling system, in particular for a motor vehicle

A technology for cooling systems and motor vehicles, which is applied in engine cooling, coolant flow control, machine/engine, etc., and can solve problems such as shortening the thermal cycle stage and reducing the cooling power of the cooling medium pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

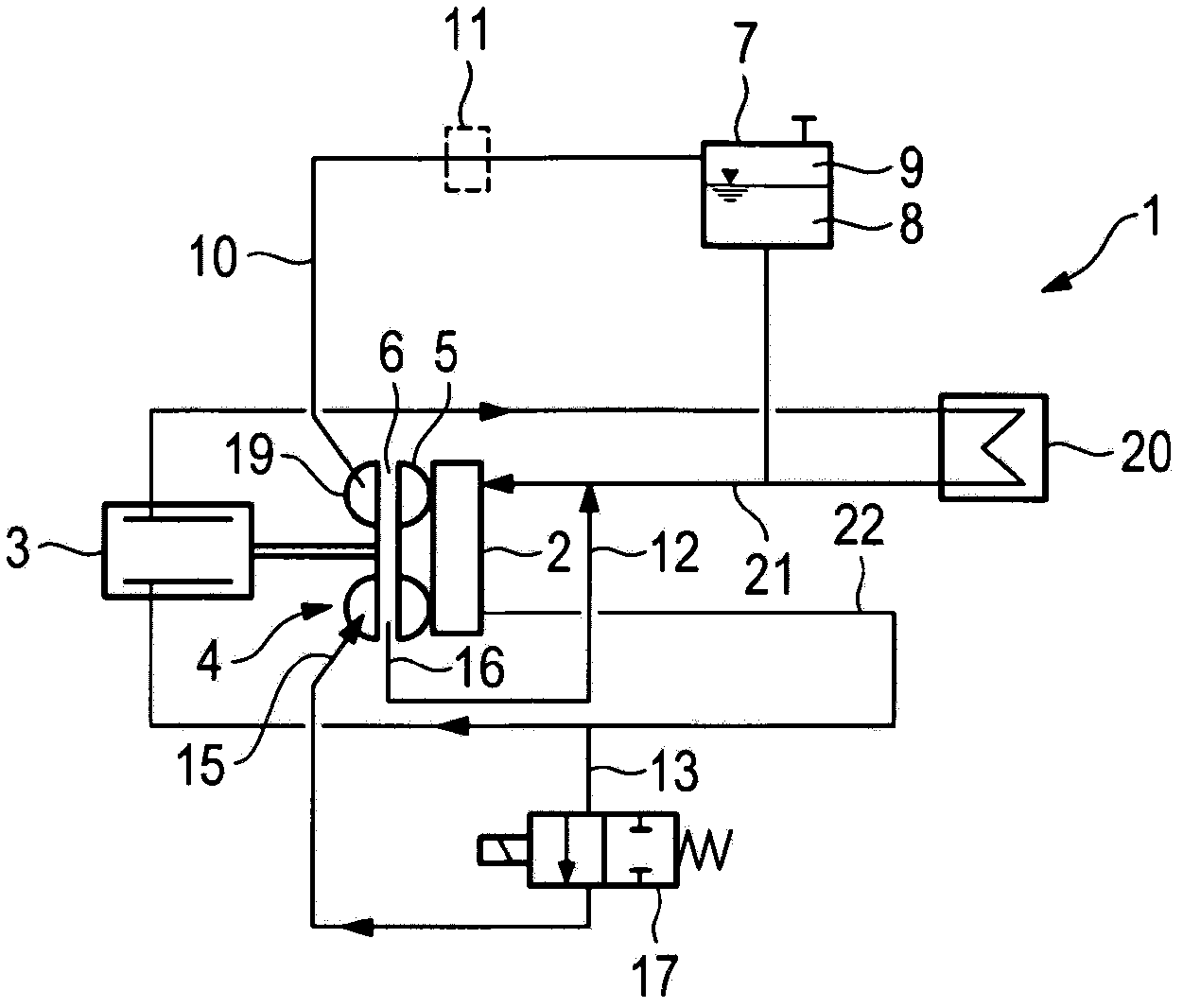

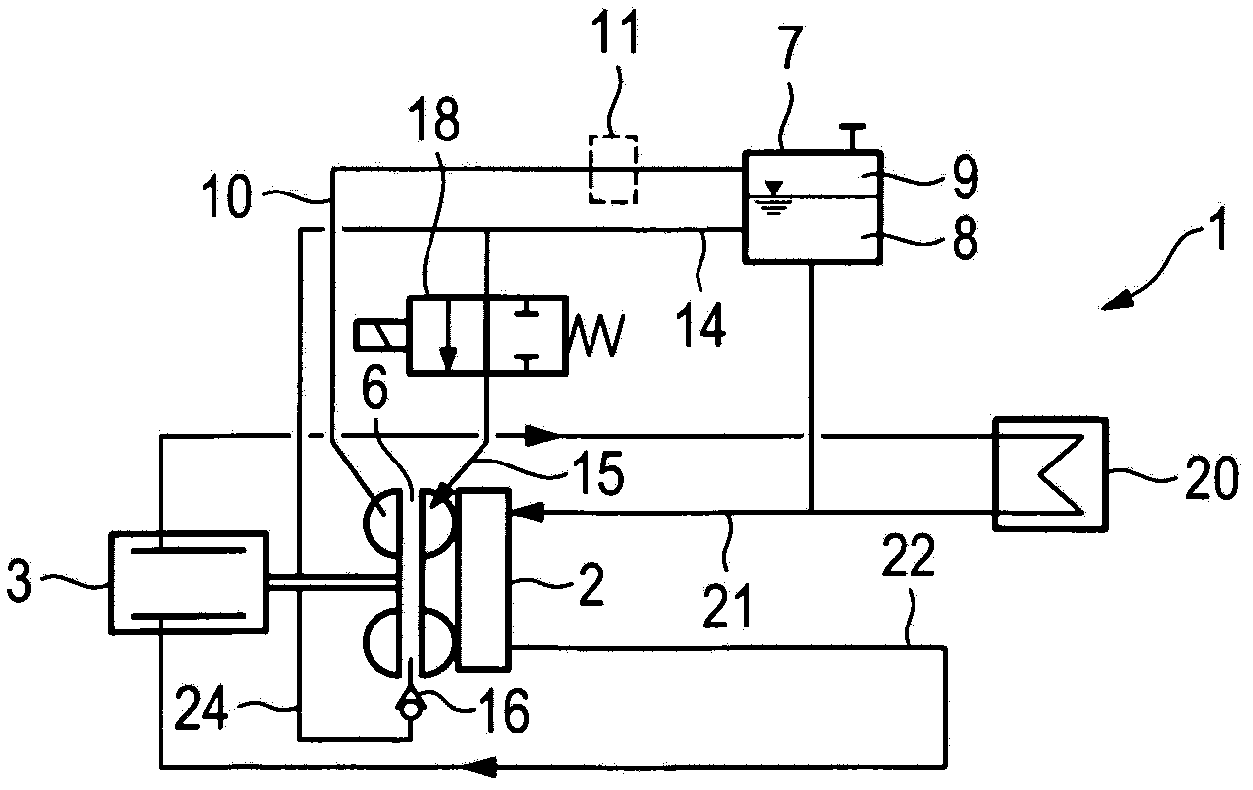

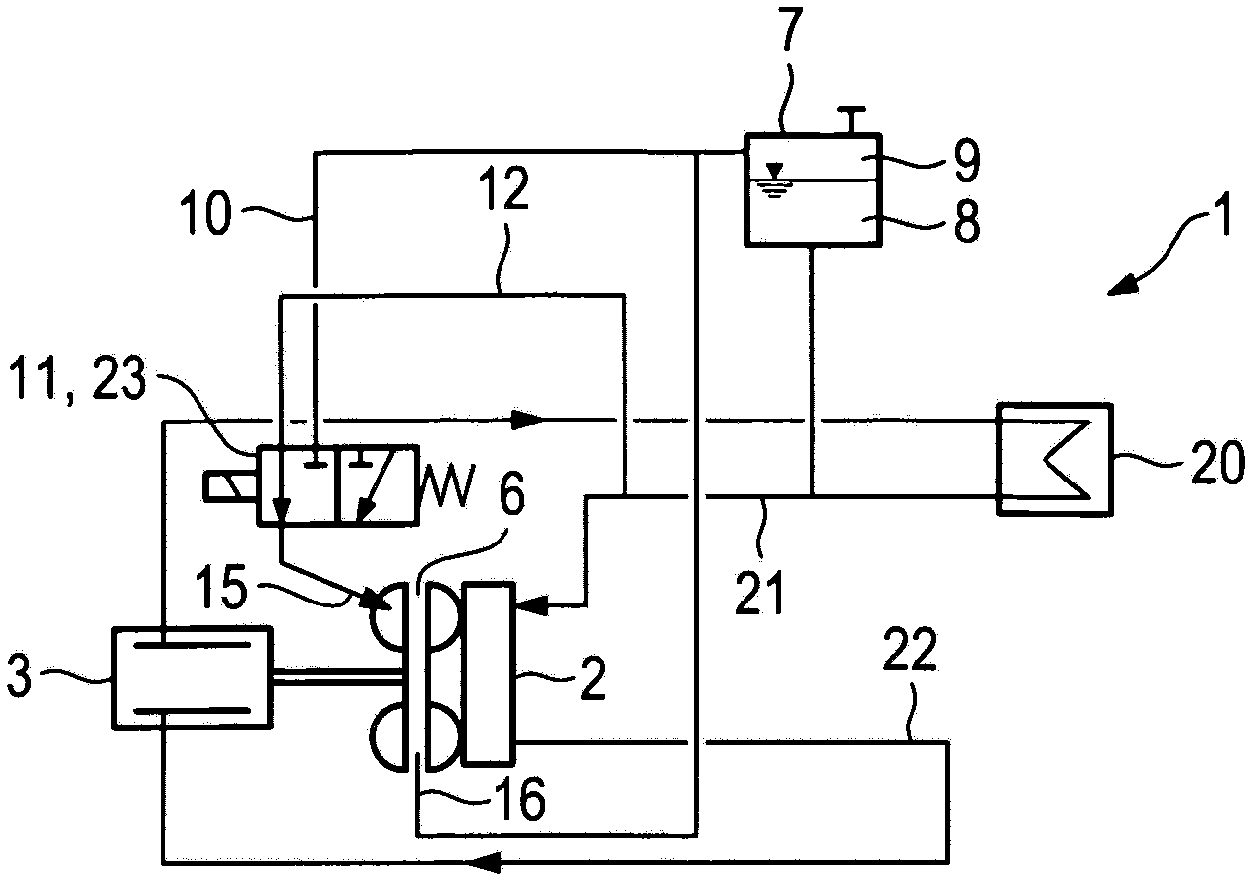

[0028] exist Figure 1 to Figure 6 All figures show schematically a cooling system with a cooling circuit 1 in which a coolant pump 2 is driven by means of a drive 3 via a hydraulic coupling 4 , wherein the hydraulic coupling 4 The turbine 5 is hydraulically driven by the working medium circulation circuit in the working chamber 6 and is driven by the pump impeller 19 , which is designed in one piece with the impeller of the coolant pump 2 . The drive unit 3 is cooled by means of a cooling medium, and the heat from the cooling medium is dissipated to the surroundings by means of a heat exchanger 20 . The cooling medium is simultaneously the working medium of the fluid coupling 4 .

[0029] The coolant pump 2 pumps coolant from the suction side 21 to the pressure side 22 . according to Figures 1 to 4 In the embodiment, the compensation container 7 is connected to the suction side 21 in a cooling medium-conducting manner / in a working medium-conducting manner. On the contrar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com