Hydrodynamic clutch

A hydraulic coupling, primary technology, applied in clutches, hydraulic resistance brakes, clutches, etc., can solve problems such as failures and expensive slip ring sealing devices, and achieve the effect of simple sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

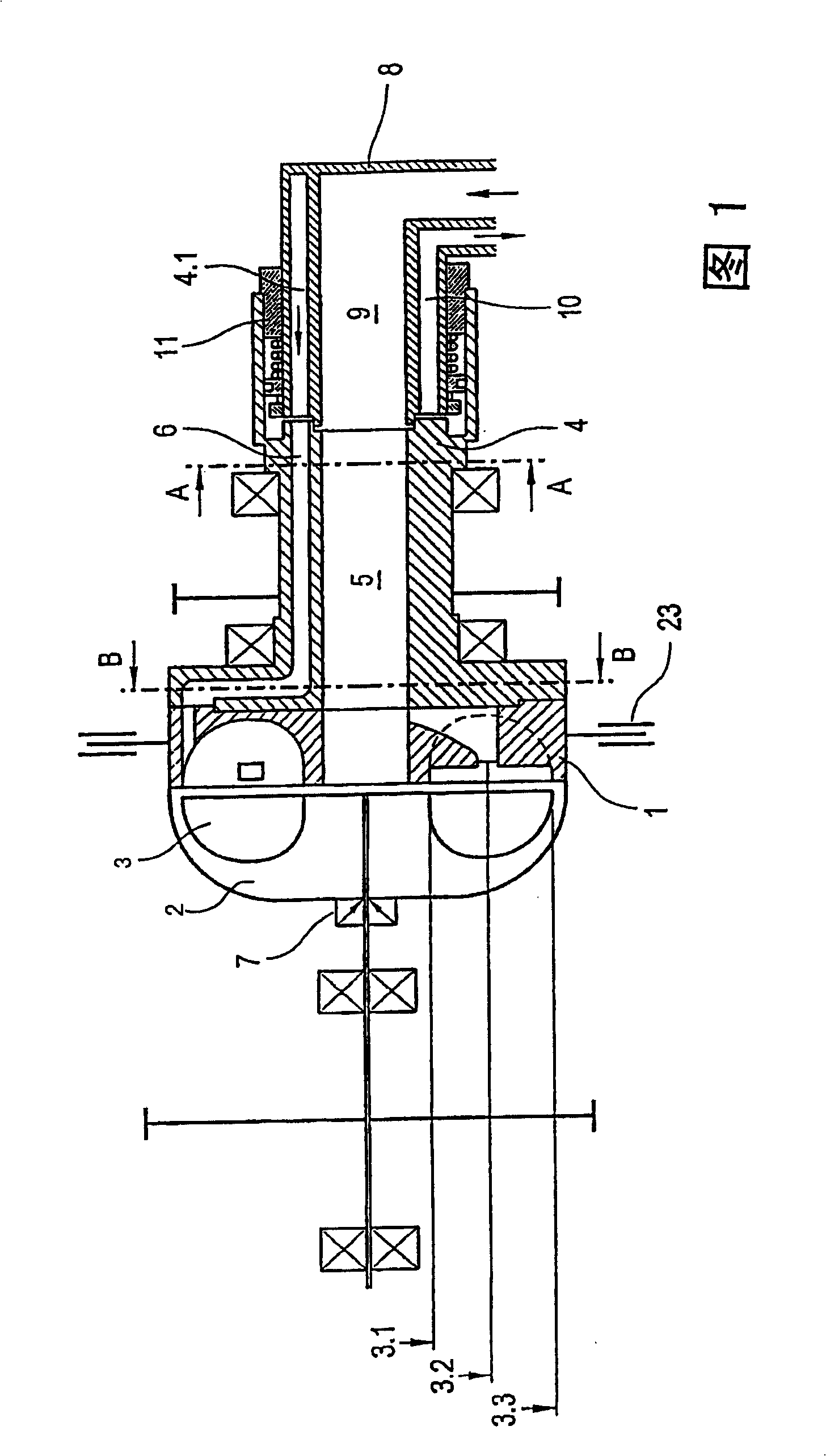

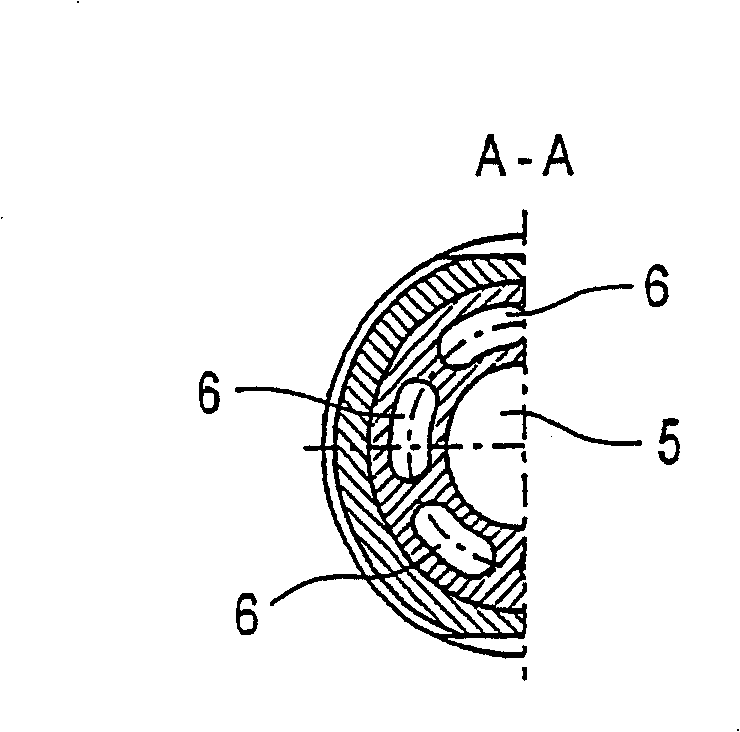

[0028] In the axial section shown in FIG. 1 , the primary wheel 1 is seen, which is arranged on the drive shaft 4 . In detail, the primary wheel 1 is screwed onto the drive shaft 4 at the end face and is sealed such that the end face contour of the drive shaft 4 forms part of the end section of the feed channel 5 in the area of the circumference 3.2 Zhongtong to the center of Studio 3. In addition, the feed channel 5 extends in the longitudinal direction on the longitudinal axis of the drive shaft 4 and is formed here as a through-opening. This has the advantage that through the axial section of the input channel 5 the screws shown, with which the secondary wheel is coupled at the end to the shaft 7, can be tightened or loosened.

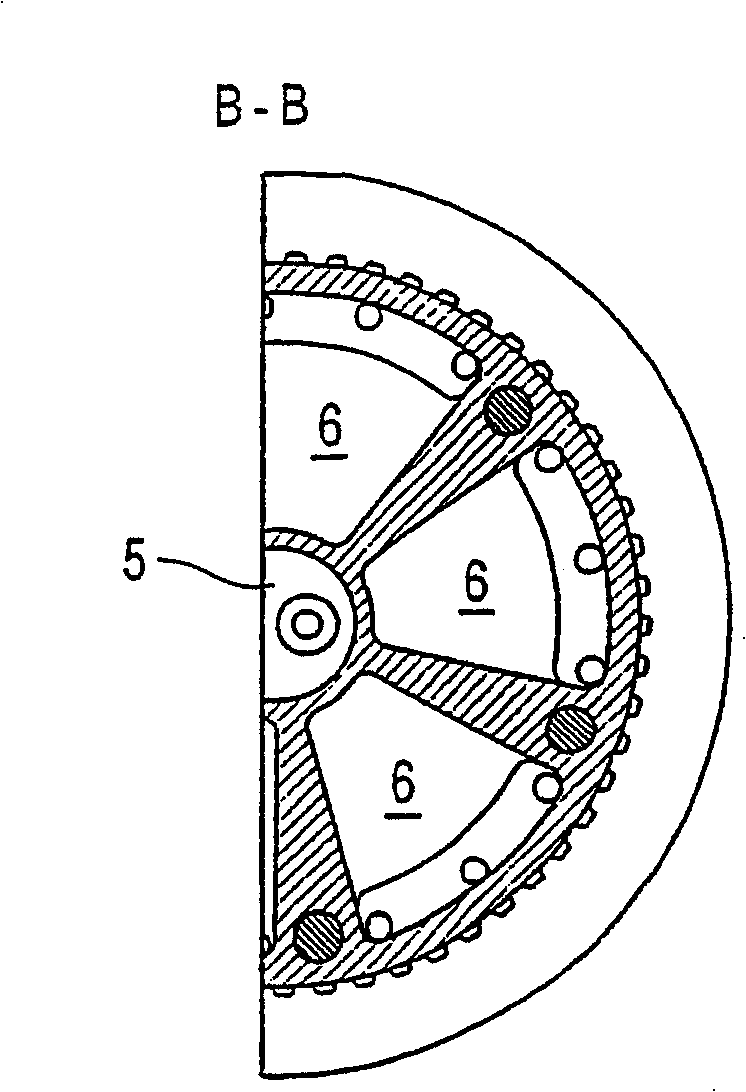

[0029] Radially outside the inlet channel 5 , a plurality of outlet channels 6 are formed in the drive shaft 4 for discharging the working medium from the working chamber 3 of the hydrodynamic coupling. A cross-section of such an outlet channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com