Multistage compressor system with hydrodynamic fluid coupling

A technology for hydraulic couplers and compressors, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as impossible, and achieve the effect of improved efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

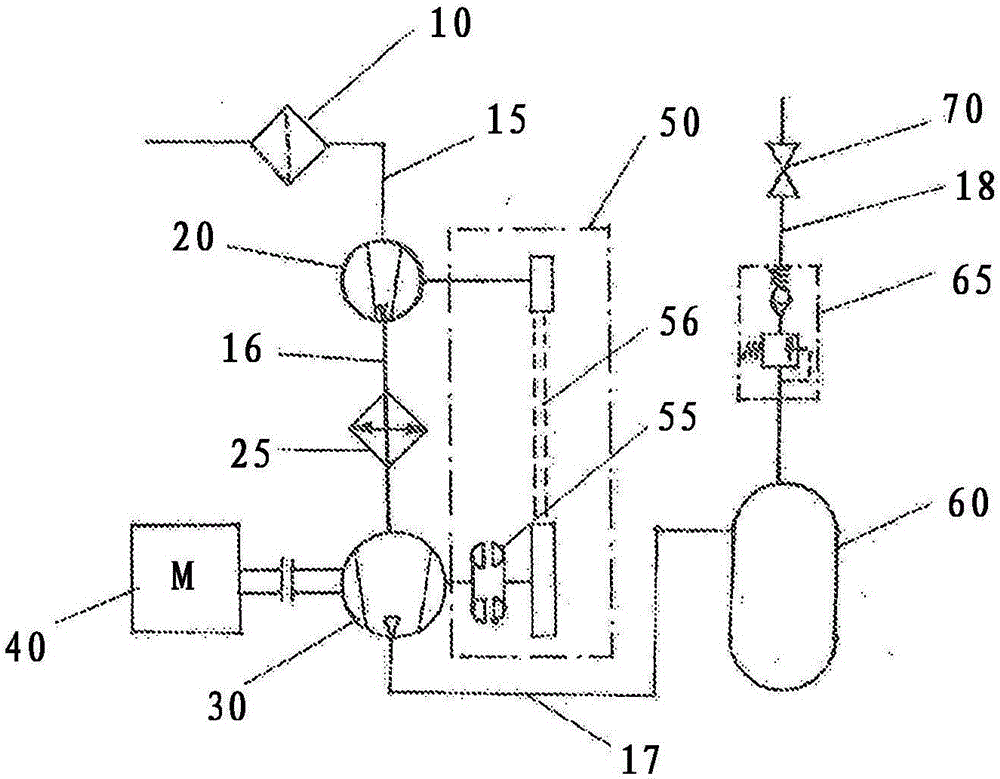

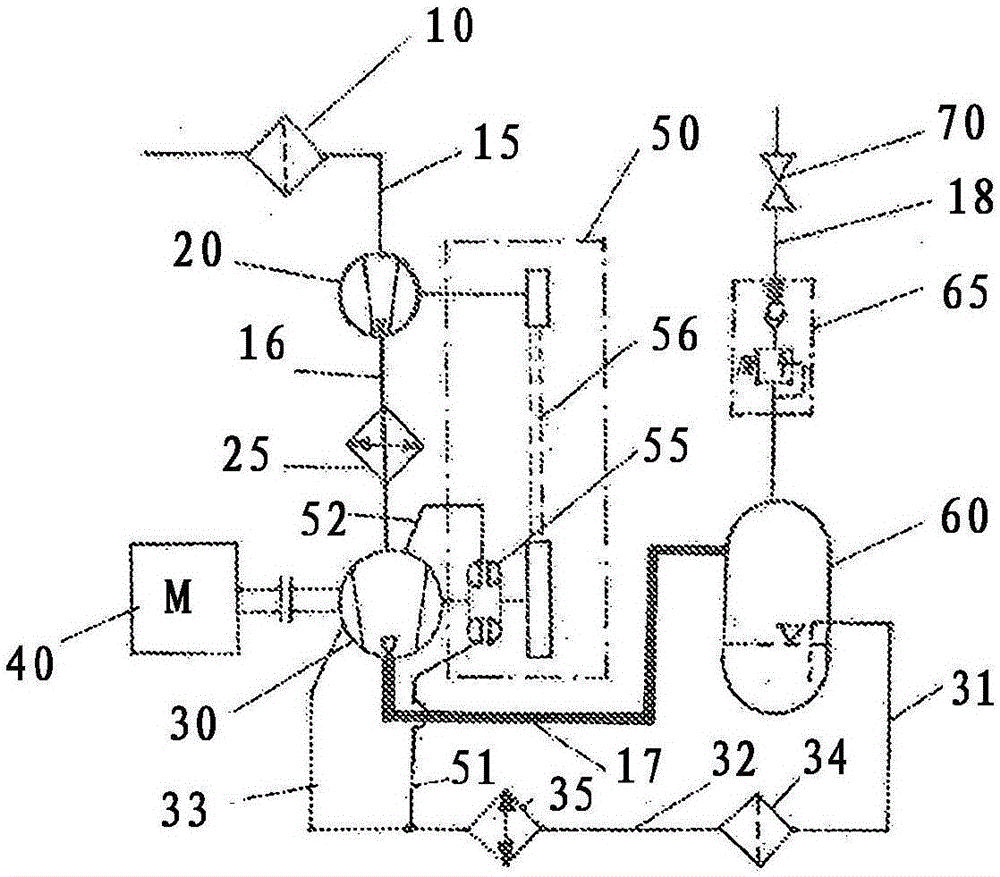

[0069] in accordance with figure 1 In the compressor installation, the suction air is cleaned by an air filter 10 and then fed to a pre-compressor 20 via a connecting line 15 . The precompressed suction air is fed to an intercooler 25 via a further connecting line 16 and cooled as best as possible. The cooled and precompressed air is then delivered to the main compressor 30 .

[0070] The main compressor can in principle be any type of compressor, also a multi-stage compressor, with or without intercooling between the individual compressor stages of the main compressor.

[0071] The main compressor 30 is driven by a drive motor 40 . The drive motor 40 can also be of any structural form that can be used to drive the compressor. This can be, for example, an electric motor, a combustion engine or any type of turbine.

[0072] In the main compressor 30 the compressed air is compressed to the desired operating pressure and delivered via the connecting line 17 to the pressure ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com