Processing die for automobile wire harness

A technology for processing molds and wire harnesses, which is applied in the field of processing molds for vehicle wiring harnesses, can solve the problem of difficult disassembly of wire inversion molds, and achieves the effects of firm fixation, improved processing efficiency, and convenient mold replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

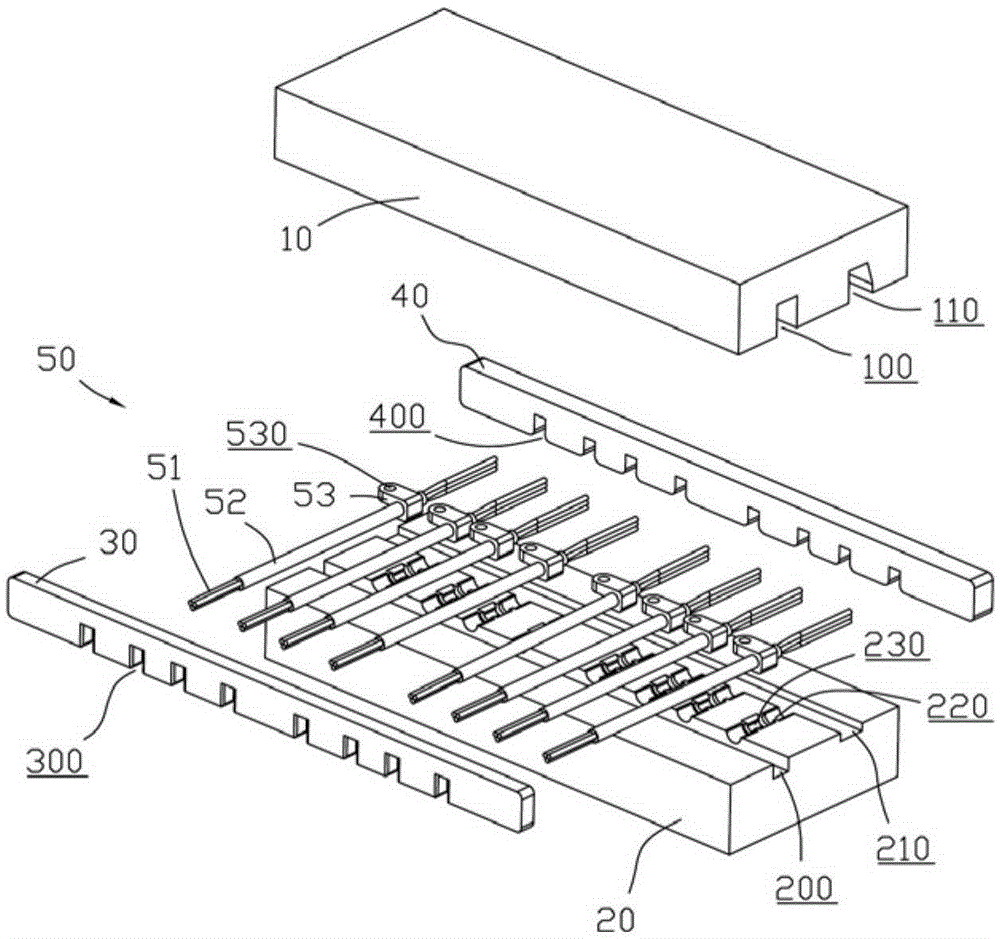

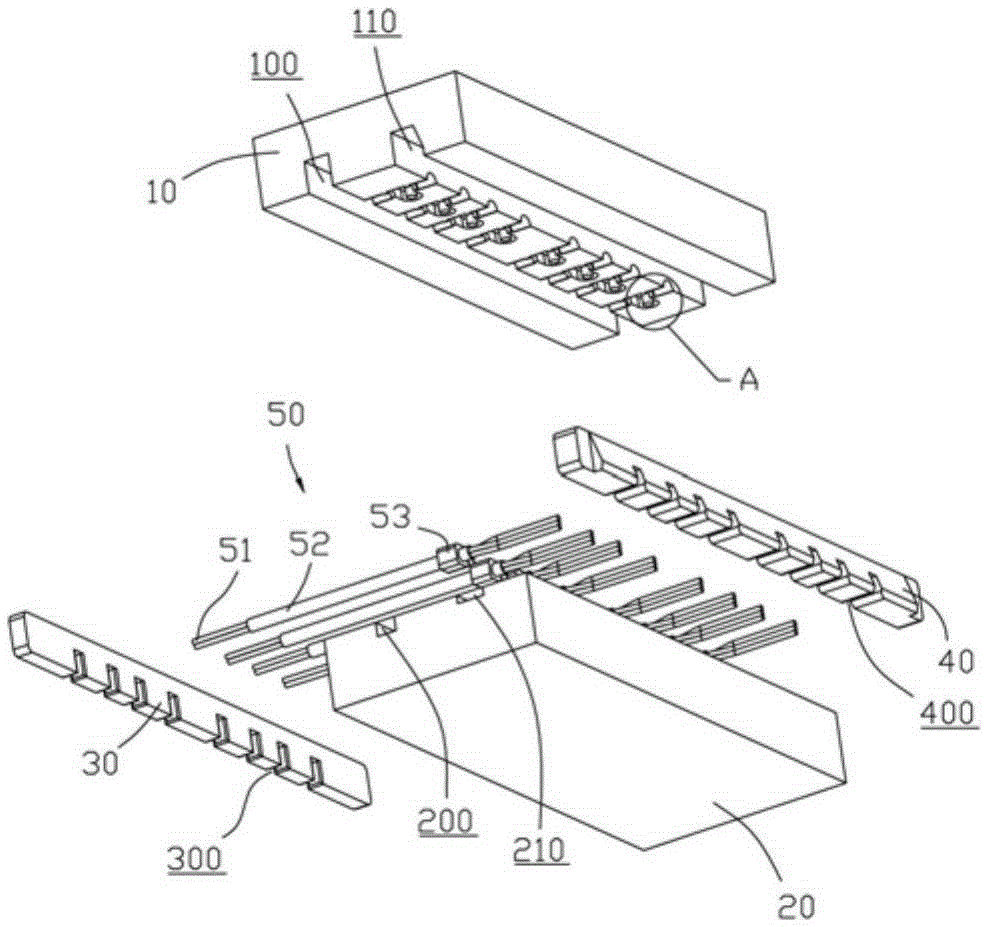

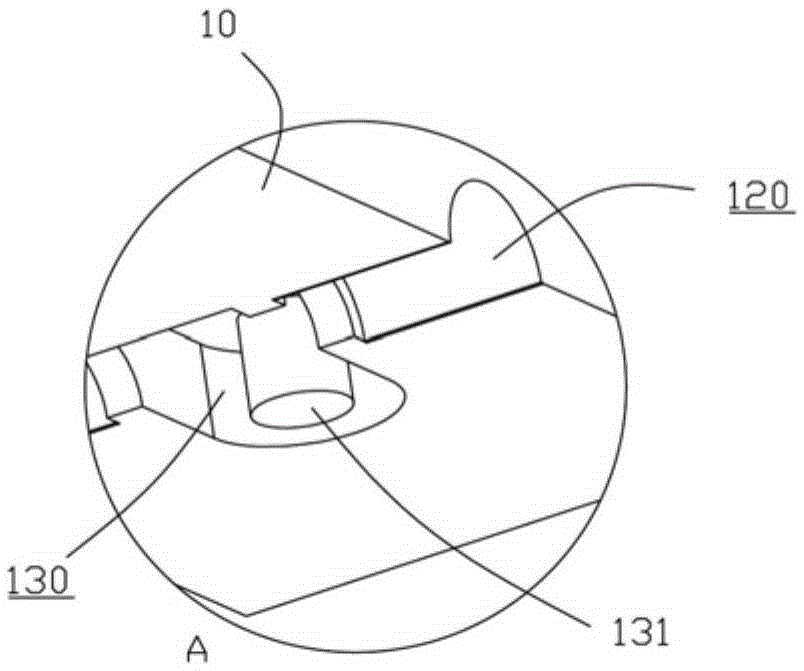

[0014] combine figure 1 and figure 2 , a processing mold for a vehicle wiring harness, comprising an upper template 10, a lower template 20, a first positioning block 30 and a second positioning block 40; the upper template 10 is located on the lower template 20, and the first positioning block 30 and the second positioning block 40 are located between the upper formwork 10 and the lower formwork 20, the bottom of the upper formwork 10 is provided with eight upper protective leather cavities 120 and upper mounting block cavities 130, and the top of the lower formwork 20 is provided with eight The lower protective bellows 220 and the lower mounting block cavity 230, the upper protective bellows 120 and the lower protective bellows 220 are bonded, and the upper mounting block cavity 130 and the lower mounting block cavity 230 are bonded.

[0015] combine figure 1 and figure 2 , the upper template 10 is provided with an upper first positioning block groove 100 and an upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com