iGPS dynamic measurement error real-time compensation method for aircraft automatic assembly

A technology of dynamic measurement and real-time compensation, applied in measuring devices, optical devices, instruments, etc., can solve problems such as redundant errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings.

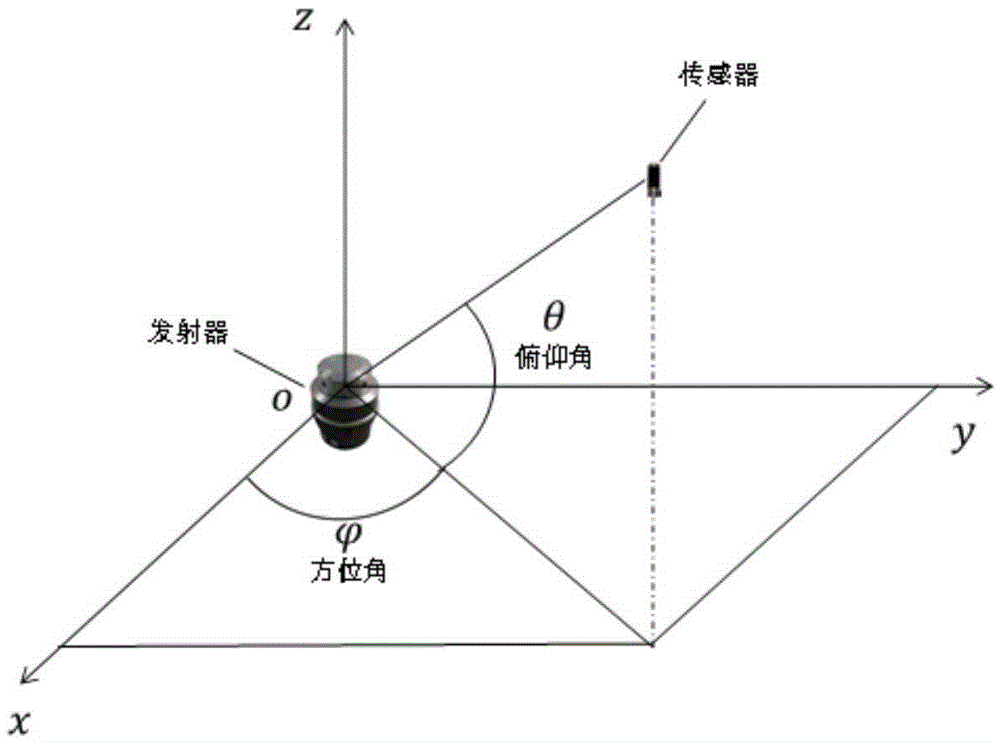

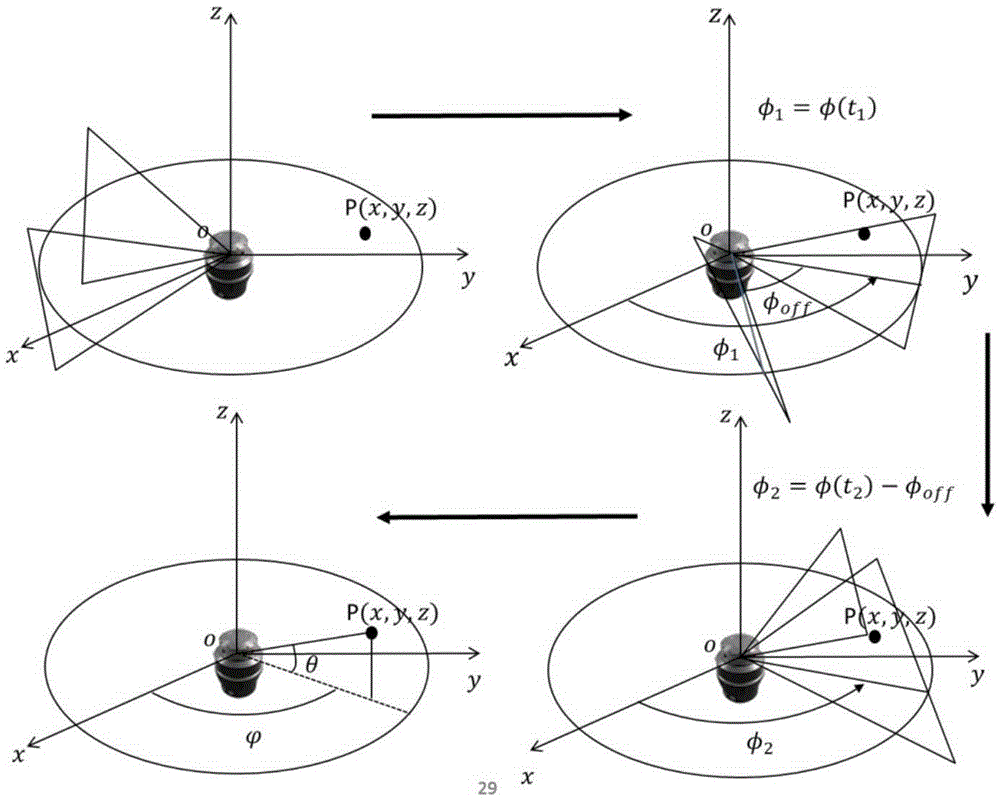

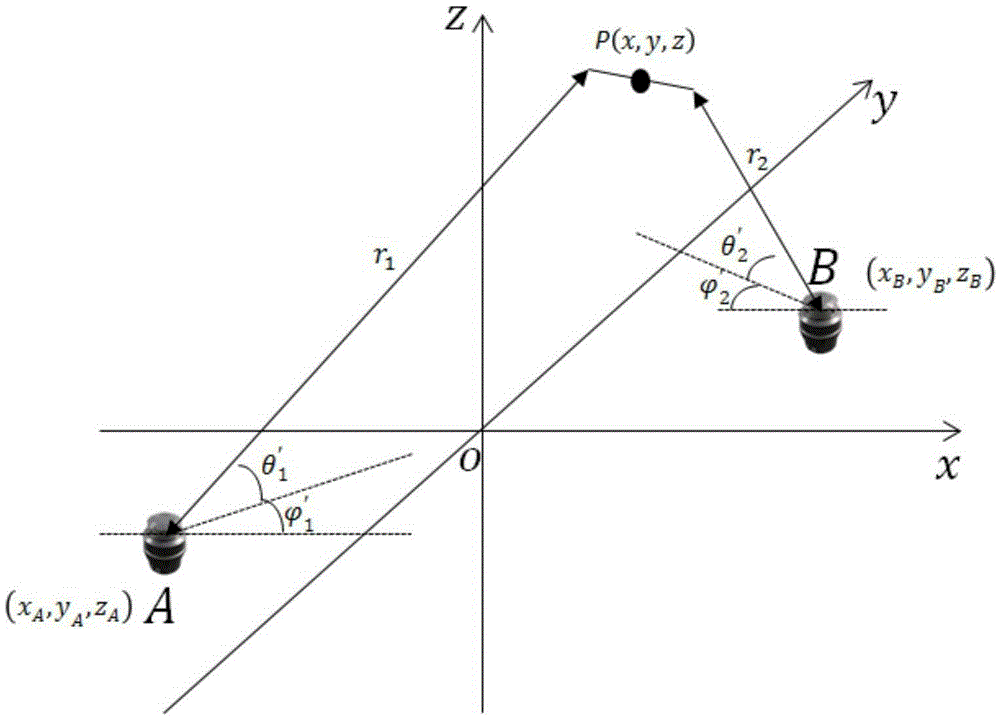

[0053] The present invention is an iGPS dynamic measurement error real-time compensation method for automatic assembly of aircraft, see Figure 1-Figure 4 , the specific steps are as follows:

[0054] Step 1. Determine the measurement target and plan the measurement range;

[0055] Step 2. Build an iGPS two-station measurement system;

[0056] Step 3, obtaining coordinate information of the measurement target;

[0057] Step 4, solving the measurement target angle;

[0058] Step five, solving the basic parameters of the transmitter beam;

[0059] Step 6. Correct the basic parameters of the transmitter beam;

[0060] Step 7, solving the coordinate information of the measurement target correction;

[0061] Step 8. Repeat steps 3 to 7 to correct the second transmitter;

[0062] Step 9, solving the dynamic measurement information of the measurement target.

[0063...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com