Cylindrical cavity molding mechanism of water soluble film packing machine

A water-soluble film, forming mechanism technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low packaging efficiency, underutilized production resources, intermittent and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objectives, technical solutions and advantages of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

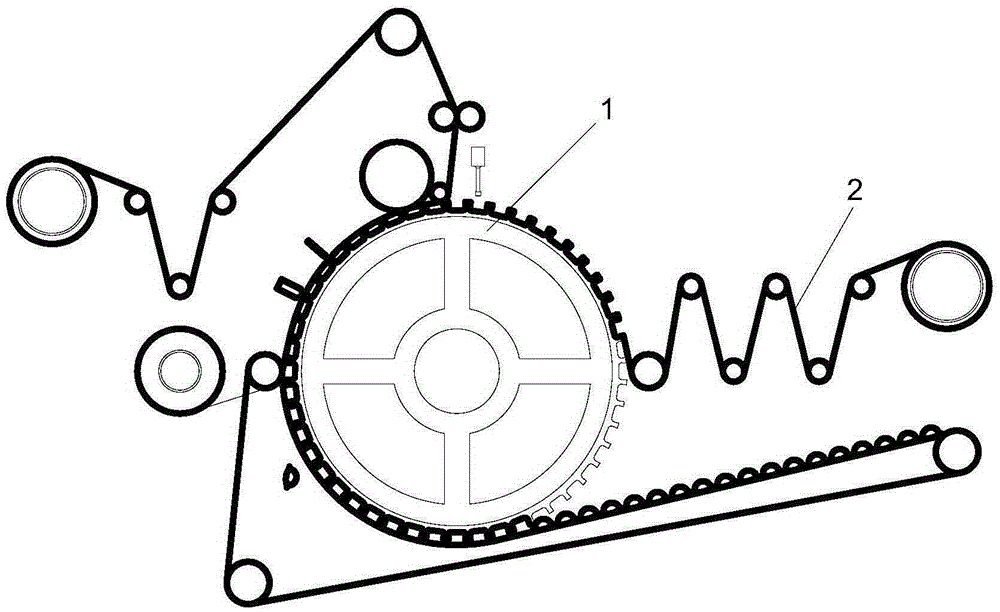

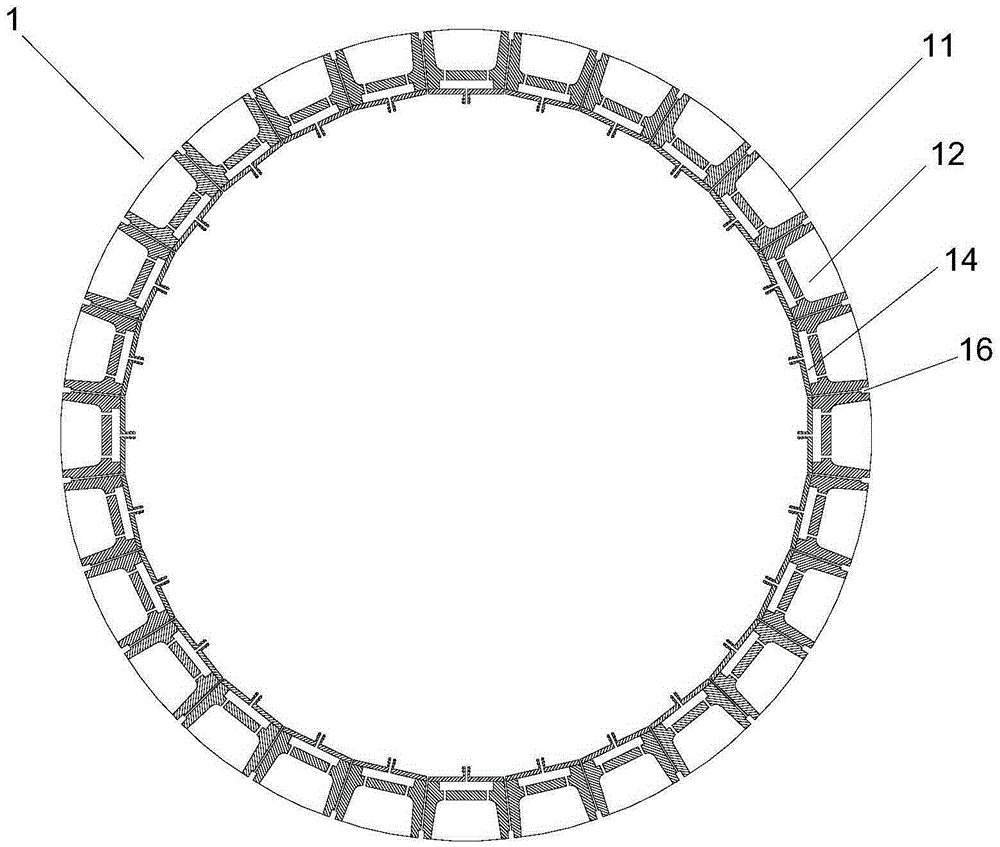

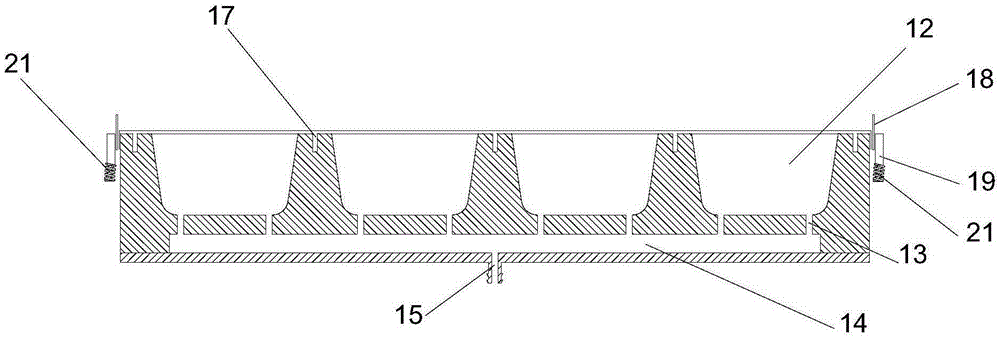

[0038] Refer to Figure 1 to Figure 3 , The present invention provides a cylindrical cavity forming mechanism 1 for a water-soluble film packaging machine, which includes a cylinder 11 connected to the frame of the water-soluble film packaging machine, and the outer surface of the cylinder 11 runs along the cylinder Several groups of cavities 12 are provided on the circumference, and the bottom of the cavities 12 is also provided with a suction component.

[0039] Further, the air extraction component includes an air extraction hole 13 arranged at the bottom of the cavity, and further includes a vacuum confluence chamber 14 and a vacuum extraction port 15. Each of the air extraction holes 13 communicates with the vacuum confluence chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com