Torque output tool

A torque output and tool technology, applied in the field of torque output tools, can solve the problems of affecting the service life of electric tools and reducing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

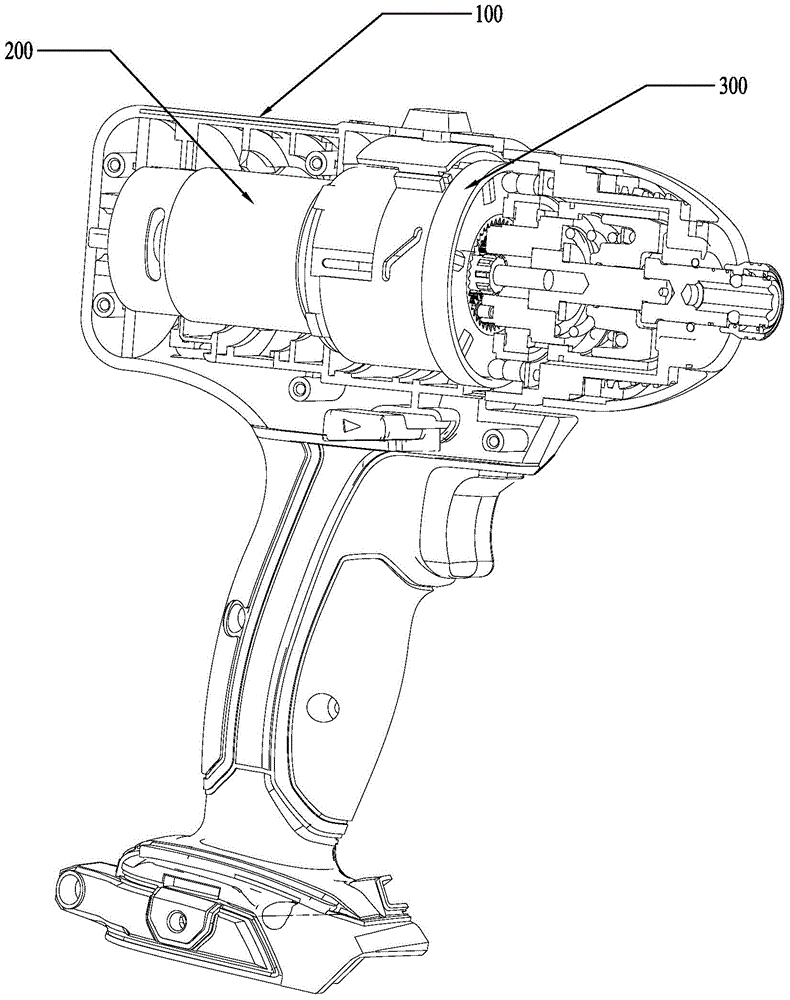

[0023] The invention provides a torque output tool. figure 1 Shown is a schematic structural view of the torque output tool of the present invention. Please refer to figure 1 , the torque output tool of the present invention includes a casing 100, a motor 200, and a transmission assembly 300, wherein the casing 100 forms a housing space (not shown) for accommodating the motor 200 and the transmission assembly 300, and the motor 200 is arranged in the storage space formed by the casing 100 The transmission assembly 300 is driven by the motor 200 and can transmit and output the power generated by the motor 200 .

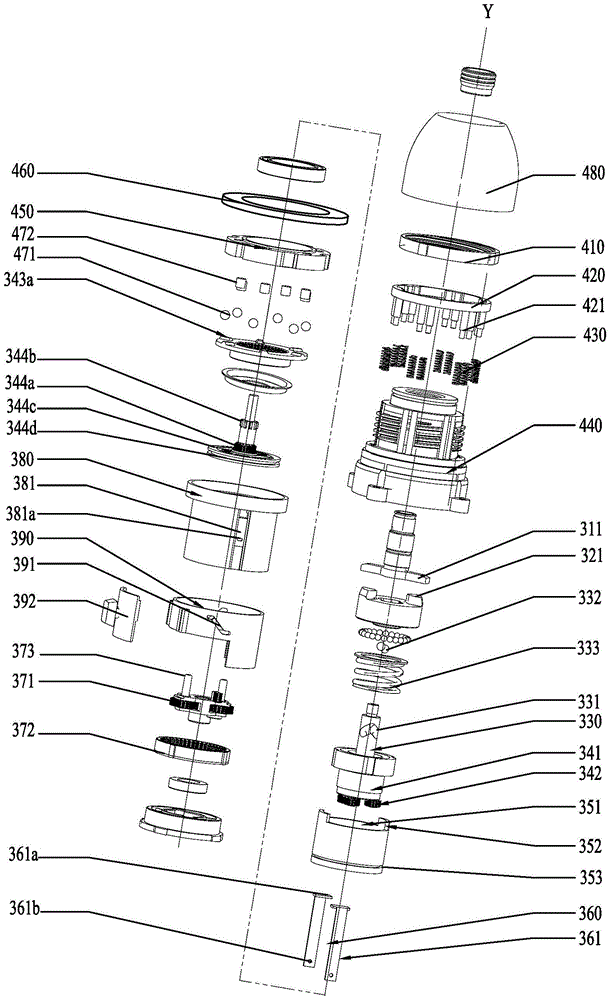

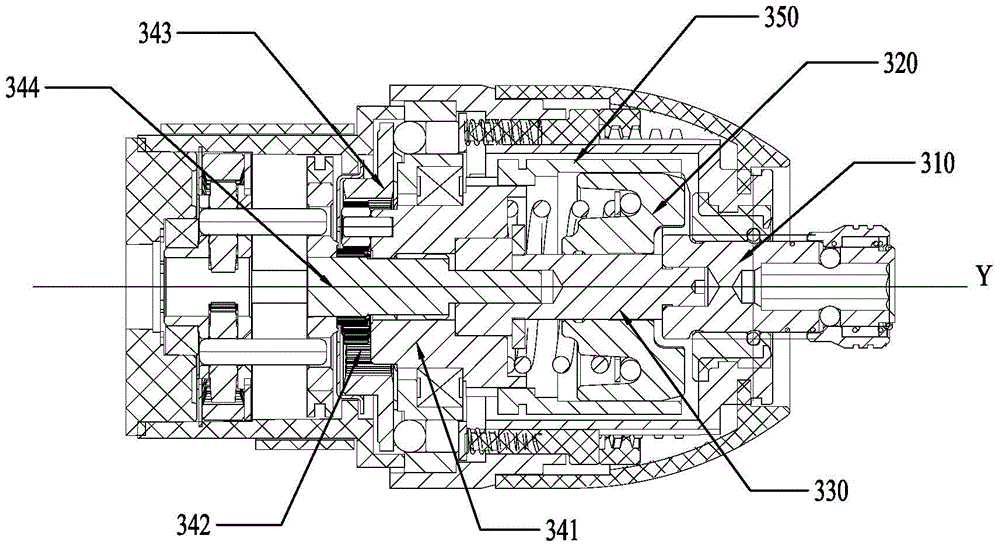

[0024] figure 2 shown as figure 1 Schematic diagram of the explosion of the middle part of the structure; image 3 shown as figure 1 Schematic cross-sectional view of the middle part structure, at this moment, the first cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com