Double-roller extrusion-type long pepper hat-removing device

A technology of roller extrusion and long pepper, which is applied in the field of double-roll extrusion type long pepper uncapping device, which can solve the problems of uncapped pepper processing, large labor force, pepper injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

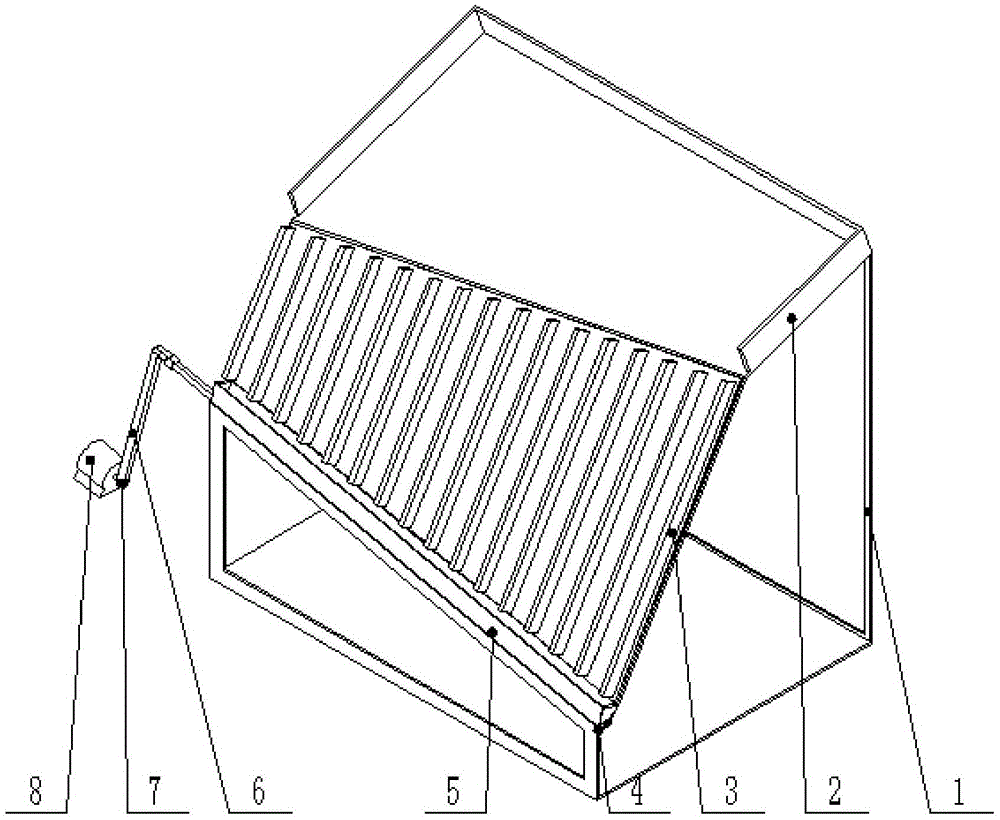

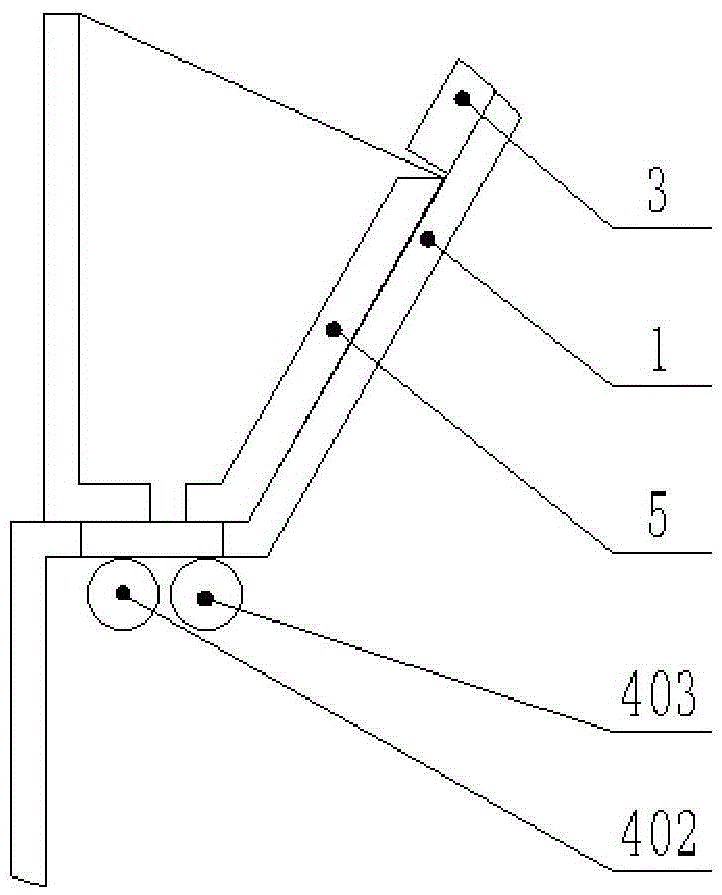

[0015] A double-roll extrusion type long pepper cap removing device is composed of a bracket 1, a feed hopper 2, a feed chute 3, a double-roll extrusion device 4, a feed guide 5, a timing belt 6, a motor timing pulley 7 and a motor Composed of 8, it is characterized in that: the feed hopper 2 is fixed on the top of the support 1, the feed chute 3 is fixed on the slope in front of the support 1, the guide groove 5 is fixed on the slope of the support 1 below the feed trough 3, and the double The roller extruding device 4 is fixed on the inside of the support 1 below the material guide groove 5, and the motor synchronous pulley 7 is installed on the motor 8, and the motor synchronous pulley 7 is connected with the double roller extruding device 4 by a synchronous belt 6.

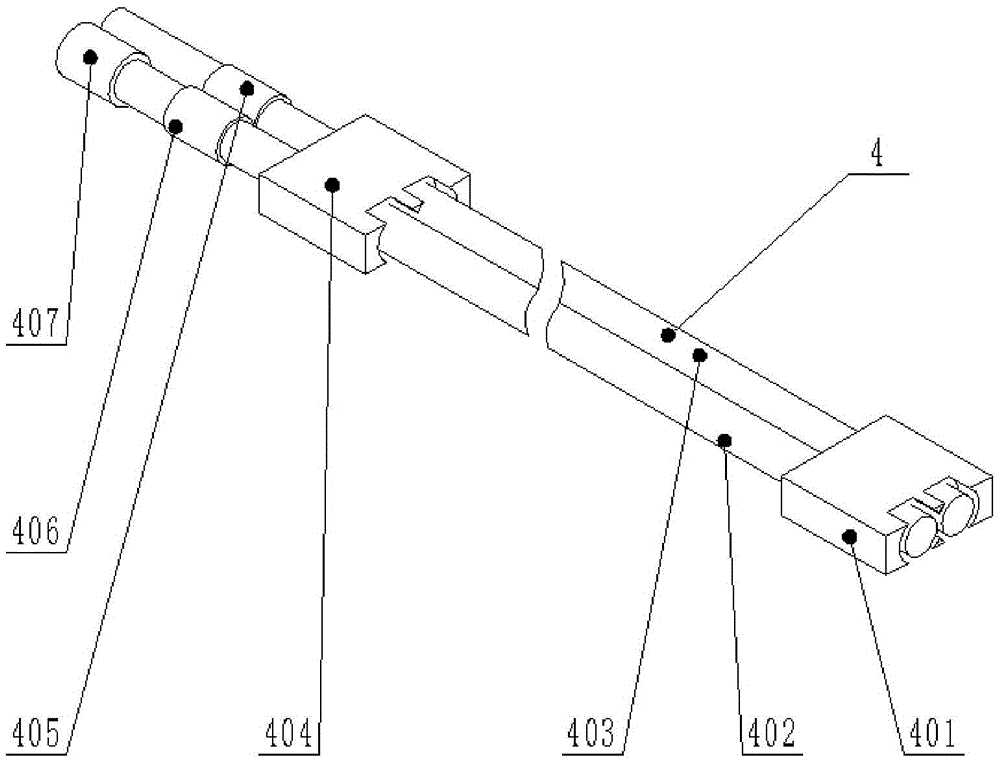

[0016] Described twin-roll extrusion device is made up of No. I bearing 401, No. I roller 402, No. II roller 403, No. II bearing 404, No. II gear 405, No. I gear 406 and synchronous pulley 407, and No. I gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com