Resin reaction still

A technology of reactor and reactor body, which is applied in the field of resin reactors, can solve the problems of affecting the process, residue, and relatively high temperature requirements, and achieve the effects of high heating efficiency, low cost, and sufficient stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

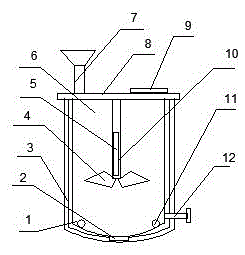

[0012] refer to figure 1 A kind of resin reactor shown, comprises resin reactor body 1, and described resin reactor body 1 is provided with kettle body 6, and the most bottom of described kettle body 6 is provided with rotating device 2, and described resin reactor body 1 A stirring rod 10 is provided, and the stirring rod 10 is installed on the top of the kettle body 6, and the resin reactor body 1 is provided with a rotating blade 4, and the rotating blade 4 is installed on the bottom of the stirring rod 10, and the resin reactor The body 1 is provided with a heating device 5 installed on the stirring rod 10 of the resin reactor body 1 . The resin reactor body 1 is provided with a temperature detecting device 11 installed at the lower part of the reactor body 6 .

[0013] The resin reactor body 1 is provided with a temperature indicator 9 installed on the top of the sealing cover 8 .

[0014] The resin reaction kettle body 1 is provided with an insulating layer 3 installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com