Quickly-connected inserting sheet, contactor with quickly-connected inserting sheet and assembly method thereof

A technology of connectors and contactors, which is applied in the direction of relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of small interference, large interference of quick-connect plugs, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

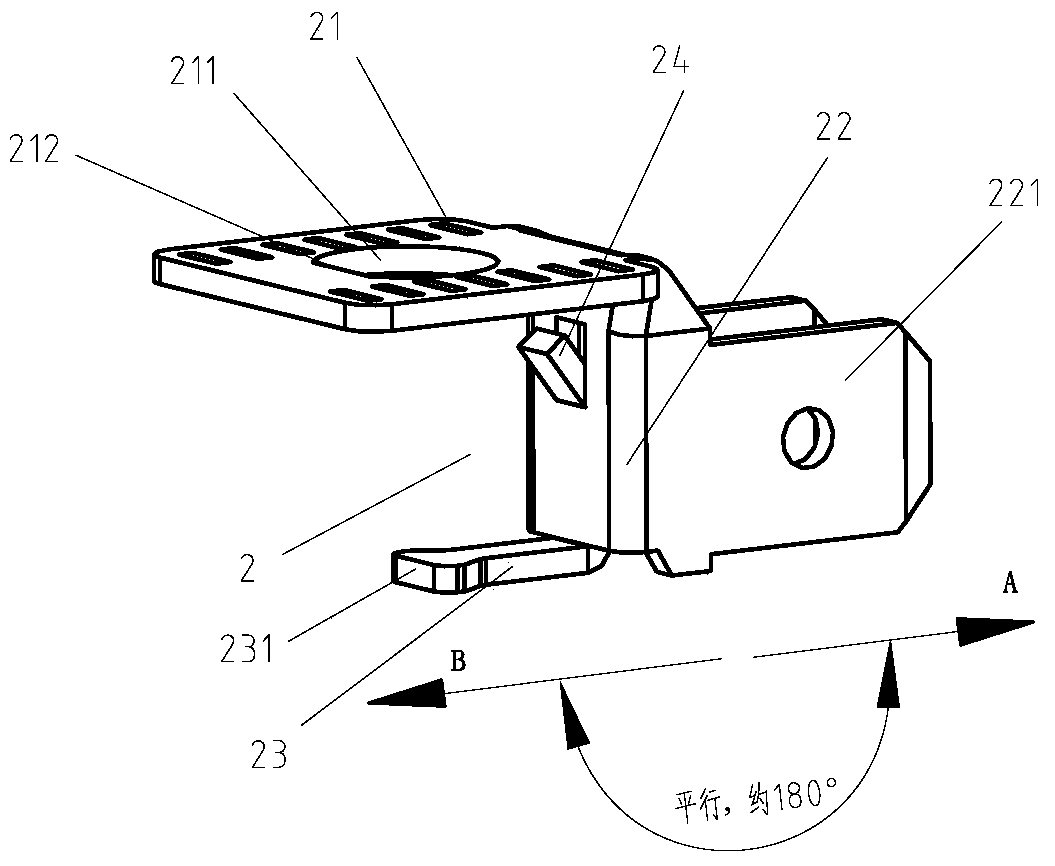

[0038] see Figure 2 to Figure 7 As shown, a quick-connect insert of the present invention includes a head 21 used to connect with a connection terminal, a middle part 22 provided with an insert 221 used to connect with a wire socket and used to fix the body shell The tail portion 23 of the quick connector is bent to a position approximately parallel to the head 21, and the end of the tail portion 23 is provided with a clamping head 231 for locking the body.

[0039] The tail portion 23 of the quick-connect insert is configured as a T-shaped structure, and the chuck head 231 is a T-shaped head.

[0040]The middle part 22 of the quick-connect insert is also provided with a convex bud 24 facing away from the direction of the insert, and the convex bud 24 is placed obliquely upward.

[0041] The convex bud 24 is formed after the body of the middle part of the quick-connect insert is torn apart.

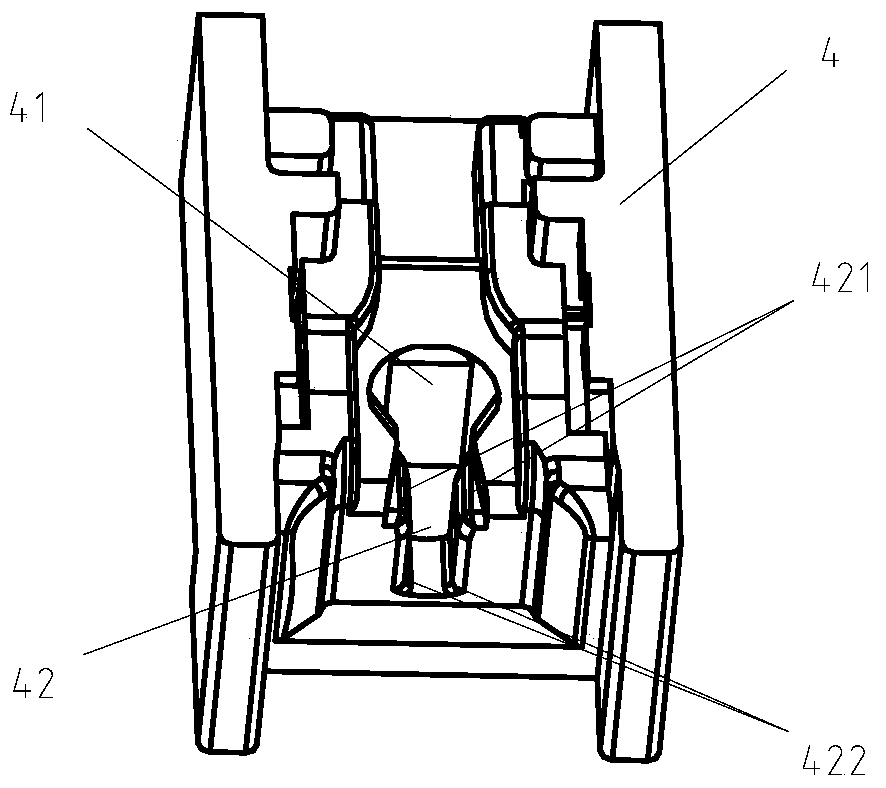

[0042] A contactor with a quick-connect insert of the present invention includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com