Container storage device

A storage device and container technology, applied in the field of cargo loading and unloading, can solve the problems of difficult container classification inventory, cumbersome operation of goods in and out, and achieve the effects of reducing storage costs, enhancing operational efficiency, and improving space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

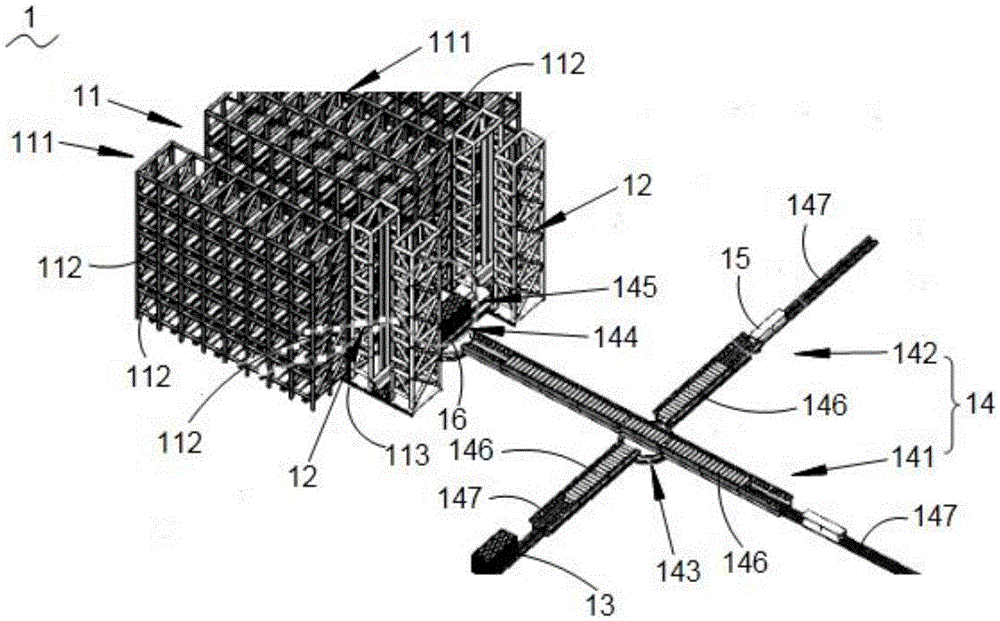

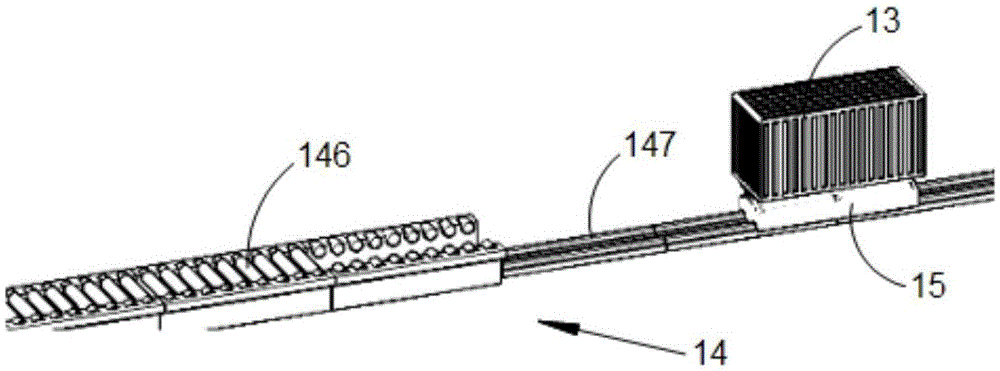

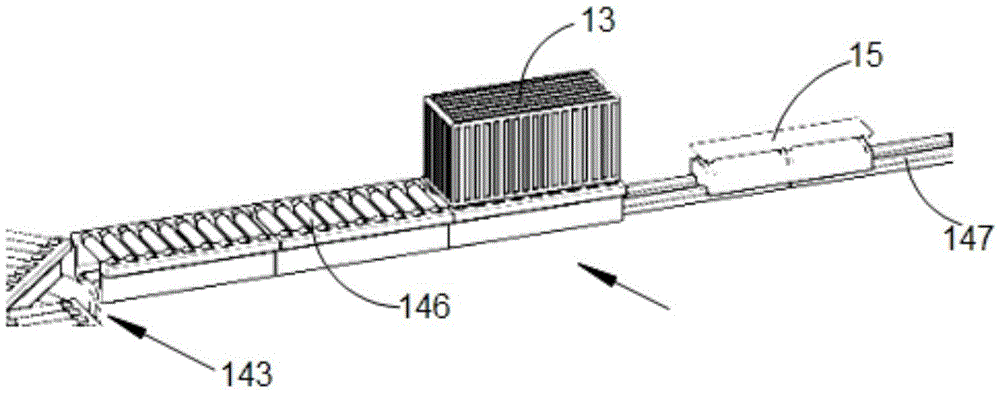

[0022] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0023] As we all know, the goods in my country's container terminals are stored in a layer-by-layer stacking manner. In the traditional sense, warehouses only have the function of providing space for goods, which is called "static storage". Obviously, in order to save inventory space, the existing warehouses stack the goods layer by layer, which is not only difficult to classify and store a single container, but also the operation of entering and exiting goods is cumbersome. For example, when it is necessary to pick up the goods at the bottom of the warehouse, it is bound to be time-consuming and labor-intensive. Firstly, the upper-level goods are removed. In today's high labor cost, it has seriously led to an increase in operating costs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com