Device and method for monitoring multi-axis fretting corrosion fatigue damage of hoisting wire rope in thousand-meter deep well

A monitoring device and technology for fatigue damage, which is applied in the field of multi-axis fretting corrosion fatigue damage monitoring device for hoisting wire ropes in thousand-meter-deep wells, can solve the problem of inability to consider the influence of torsional load, temperature and environmental factors of corrosive solution, and the inability to consider torsional load, temperature, etc. And corrosion environment, not suitable for flexible steel wire samples and other problems, to achieve the effect of slowing down the failure of multi-axis fretting corrosion fatigue damage of steel wire rope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the accompanying drawings.

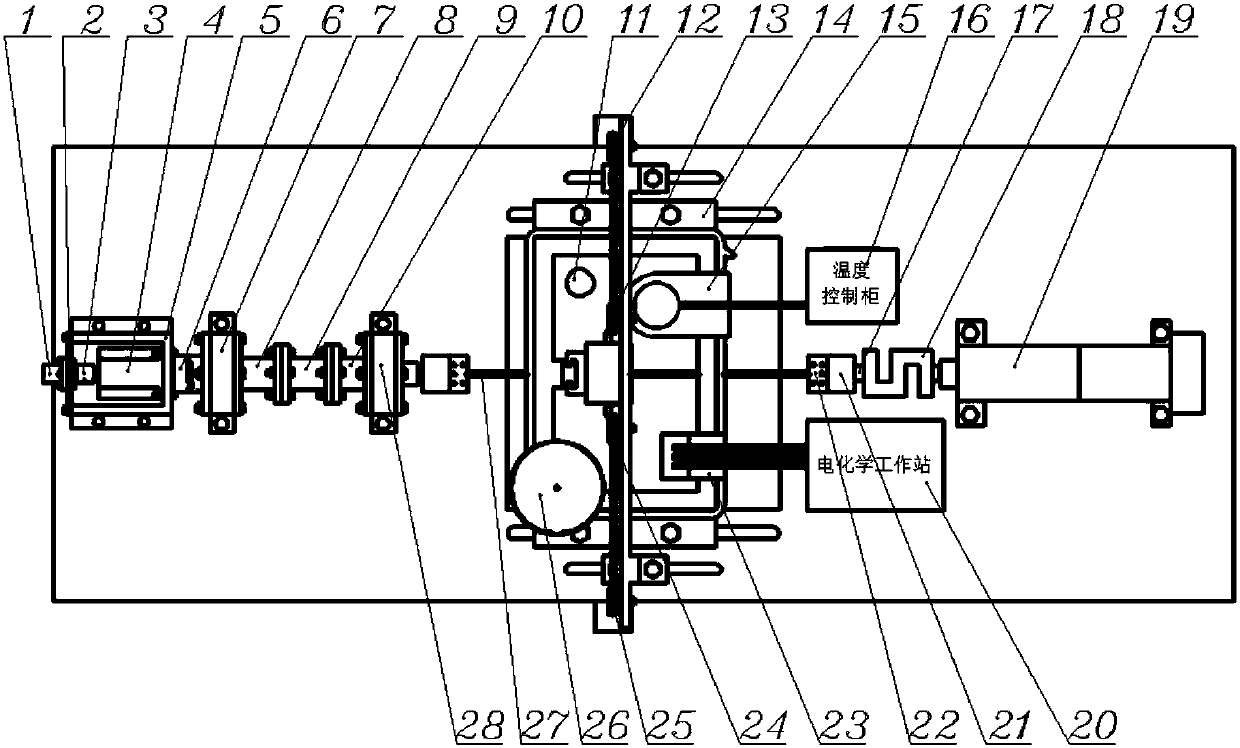

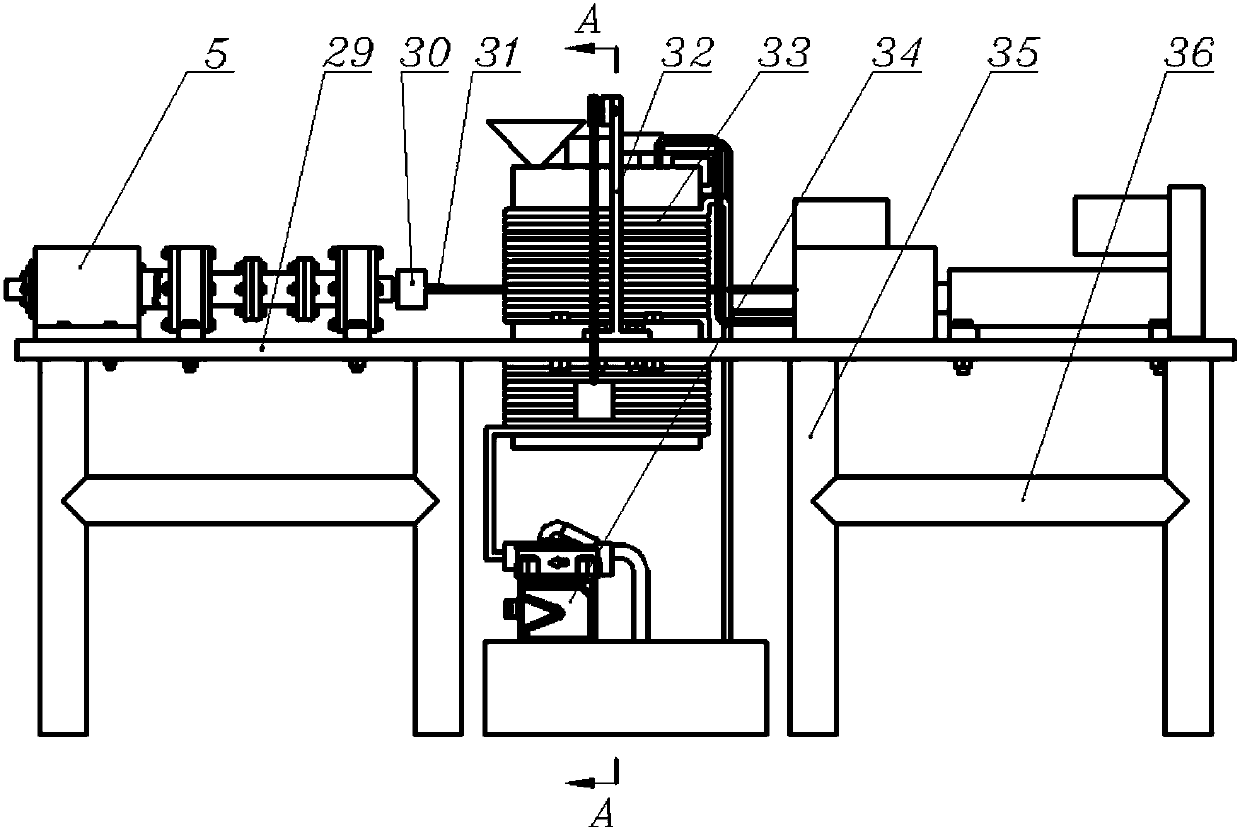

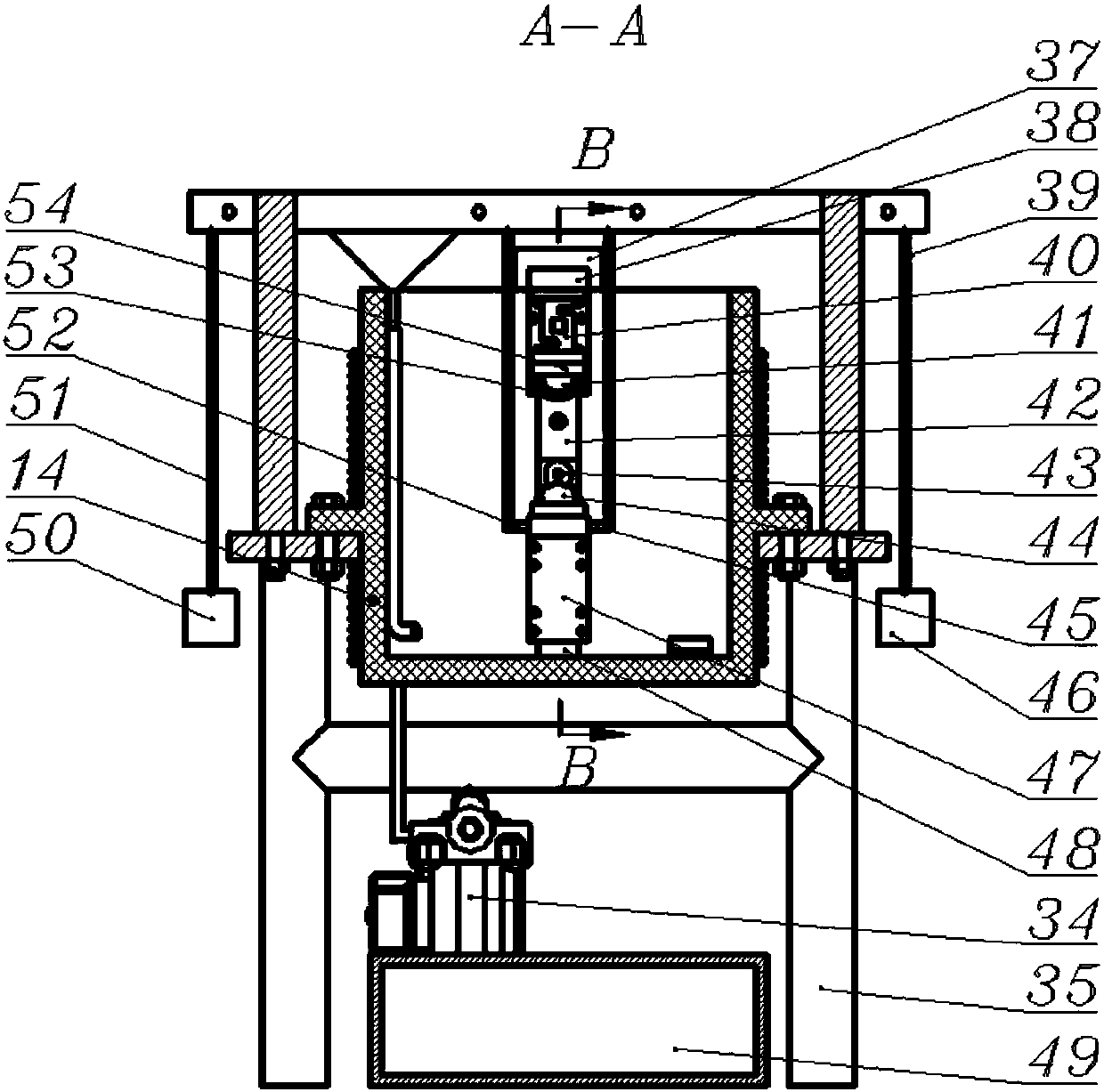

[0030] The multi-axis fretting corrosion fatigue damage monitoring device for a hoisting wire rope in a kilometer deep well of the present invention includes a base frame and a fretting system, a tension-torsion fatigue system and a constant temperature corrosion system arranged on the base frame.

[0031] Described pedestal comprises support column 35, crossbeam 36 between support column 35 and the base plate 29 that is fixed on the support column 35, offers square hole on base plate 29, and square hole both sides is provided with rectangular positioning hole A and rectangular positioning hole A. Hole B.

[0032] The constant temperature corrosion system includes a corrosion resistant box 14, a constant temperature control system, a cooling system, and an electrochemical corrosion system. The corrosion-resistant box 14 is embedded in the square hole of the bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com