Pneumatic lifting device

A kind of pneumatic lifting and gas technology, applied in the direction of lifting device, lifting frame, gas-liquid shock absorber, etc., can solve the problem that the gas spring cannot meet the needs of use, so as to enhance the new energy of the product, enhance the experience effect, and reduce the production and processing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

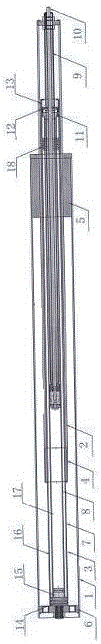

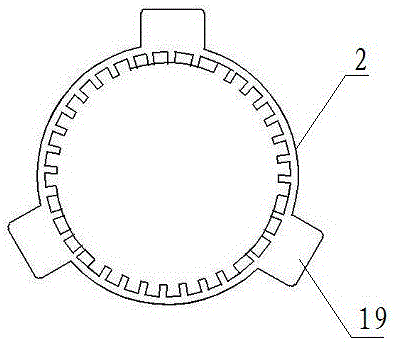

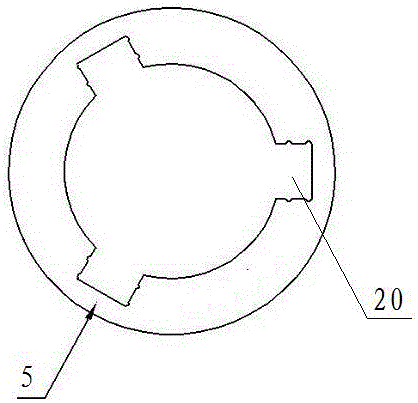

[0025] like Figure 1-6 It is a structural schematic diagram of the present invention, a pneumatic lifting device, including an outer tube 1, an outer tube 2 and an air spring 3, the outer tube 2 is placed in the outer tube 1, the gas spring 3 is placed in the outer tube 2, and the The junction of the outer tube 2 and the outer tube 1 is provided with a guide sleeve 2 5, one end of the outer tube 2 and the gas spring 3 is fixedly connected as one, and the other end is provided with a guide sleeve 4, the connection between the outer tube 1 and the gas spring 3 Spacers 6 are provided between them.

[0026] According to another embodiment of the present invention, it further includes that the gas spring 3 is composed of an inner tube 7, an oil tube 8, a piston rod body 9, a push rod 10, a ventilating support 11, an oil seal 12 and a rear top sleeve 13. The oil pipe 8 is placed in the inner pipe 7, the piston rod body 9 is placed in the oil pipe 8, the push rod 10 is placed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com