Jacquard yarn feeding wheel body

A yarn-feeding wheel and yarn-feeding technology, which is applied in textiles and papermaking, weft knitting, knitting, etc., can solve problems such as inability to feed yarn, troubles, and inelastic structure of smooth silk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

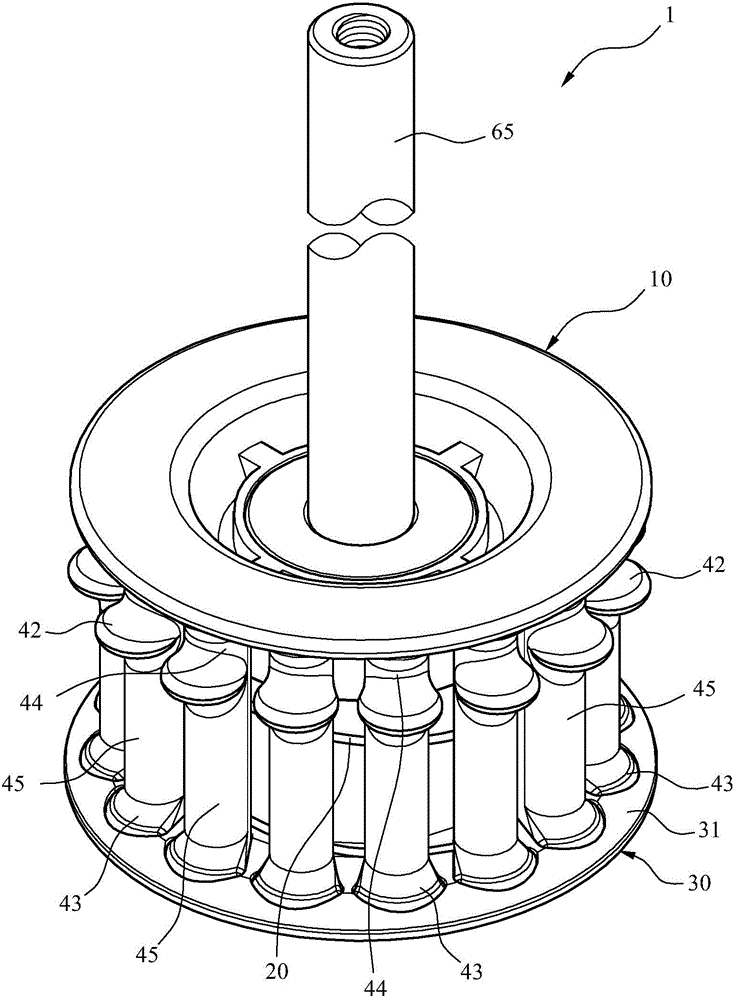

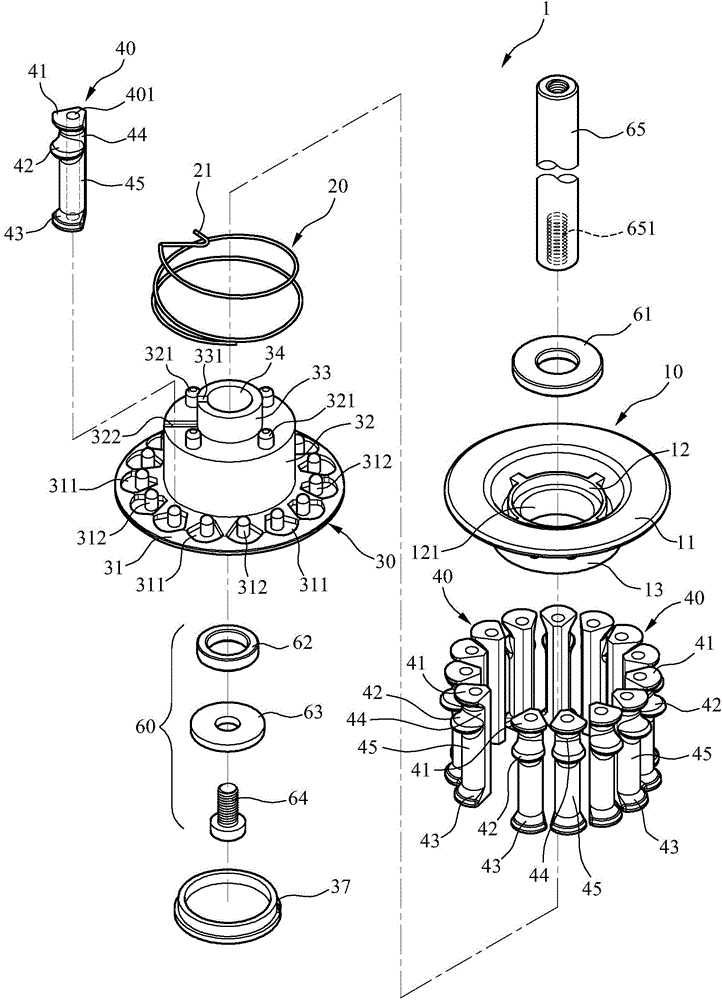

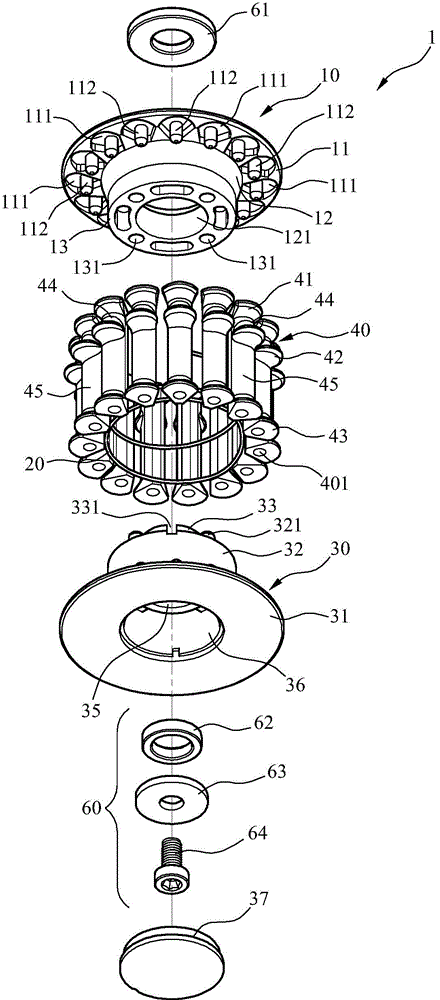

[0049] refer to figure 1 , figure 2 and image 3 , is the first embodiment of the present invention, the jacquard yarn feeding wheel body 1 includes an upper wheel cover 10, a conductive element 20, a lower wheel cover 30, a plurality of ceramic parts 40 and a wheel shaft 65.

[0050] The upper wheel cover 10 includes a ring body of the upper solid rod portion 11 , and a bearing seat 12 with a first through hole 121 is arranged at the center thereof. At image 3 Among them, the upper fixed rod portion 11 of the upper wheel cover 10 is equally spaced and annularly arranged with a plurality of upper embedded rod grooves 111, and the plurality of upper inserted rod grooves 111 are provided with protrusions 112. The first of the upper wheel cover 10 The lower periphery of the through hole 121 includes a bottom ring 13 with a plurality of first locking holes 131 .

[0051] The conductive element 20 is wound into a spring shape, and a conductive elastic hook portion 21 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com