Bobbin unloading mechanism of glass fiber drawing machine

A glass fiber and wire drawing machine technology, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of easily damaged yarn clusters and deformation of the winding drum, so as to achieve non-slip, large holding angle, and improve the life of the winding drum Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

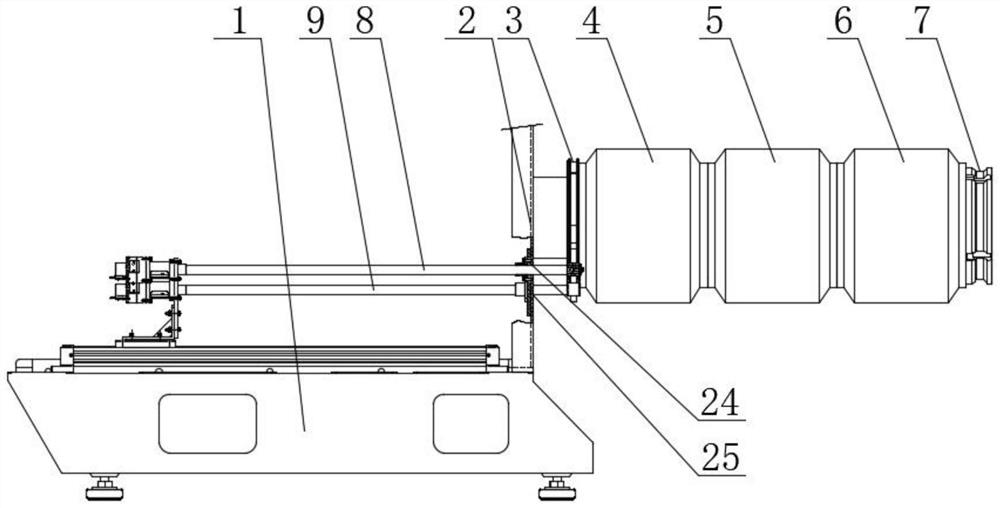

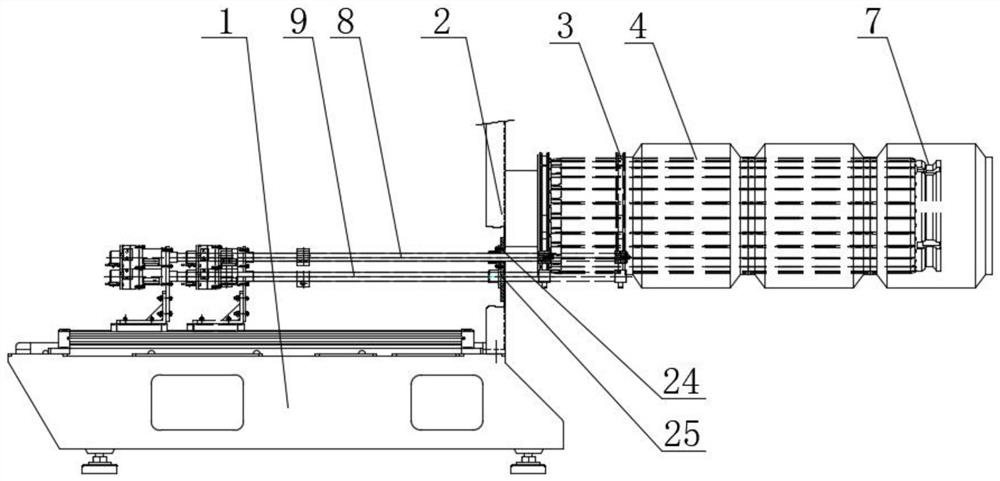

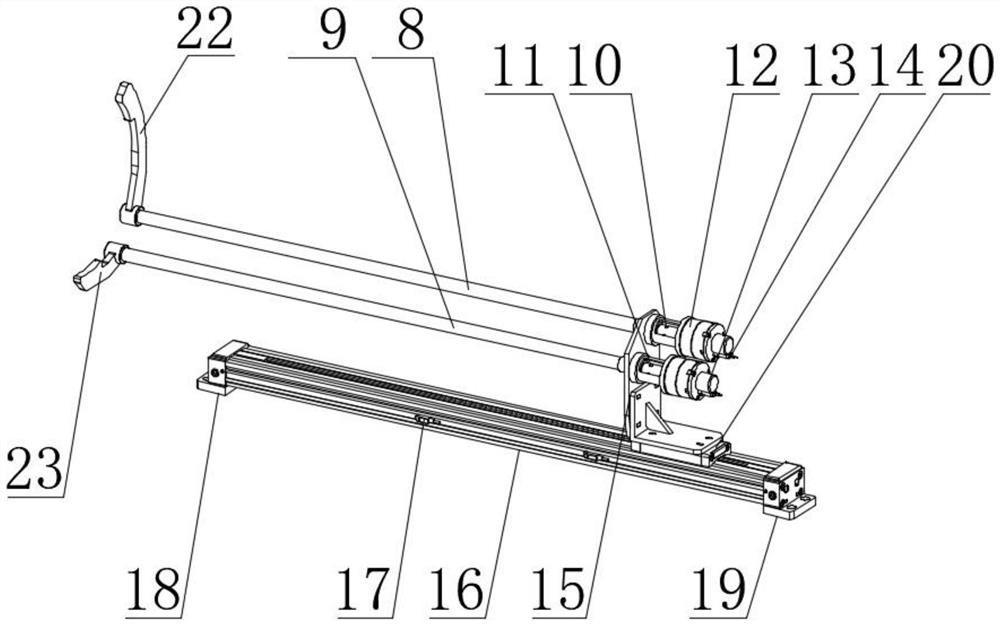

[0024] Embodiment 1: as Figure 1-5 As shown, a bobbin unloading mechanism of a glass fiber drawing machine includes a base 1 and a frame 2 arranged above the base 1, a head 7 is fixed on one side of the frame 2 to facilitate the installation of the winding bobbin 4; the head 7 is close to the base 1 One end is the tail of the machine head, away from the base 1 The end is the head of the machine head, the tail of the machine head is provided with an unloading ring 3, and the machine head 7 on the other side of the unloading ring 3 is provided with three winding wires for winding glass fibers The tube 4, the tube unloading ring 3, the wire winding tube 4 and the machine head 7 are located on the same axis, and the tube unloading ring 3 prevents the upper swing arm 22 and the lower swing arm 23 from directly pushing and winding the wire tube 4 when unloading the tube, ensuring When unloading the bobbin, it will not damage the yarn cluster and damage the winding bobbin, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com