Snow remover and manufacturing method

A manufacturing method and snow blower technology, applied to snow surface cleaning, cleaning methods, construction, etc., can solve problems such as low operating efficiency, potential safety hazards, and inability to complete snow removal operations independently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

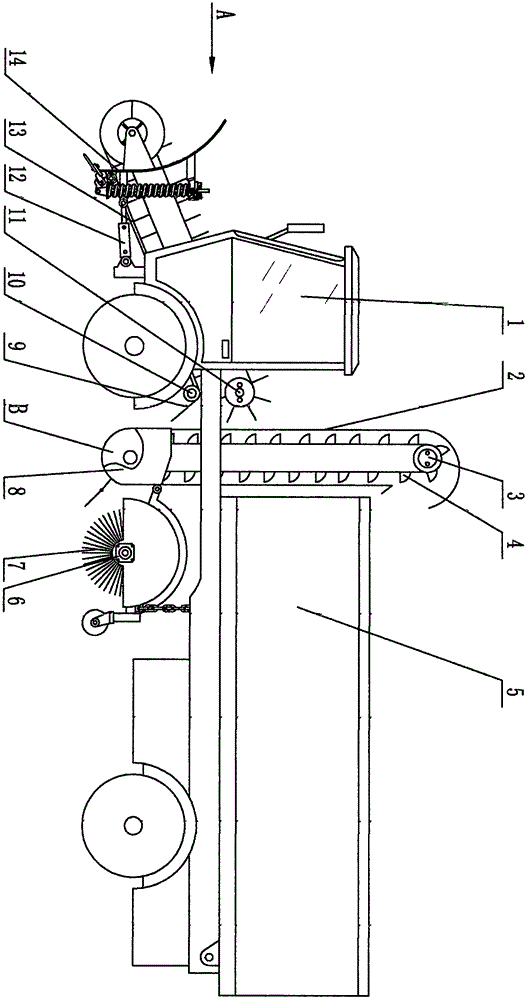

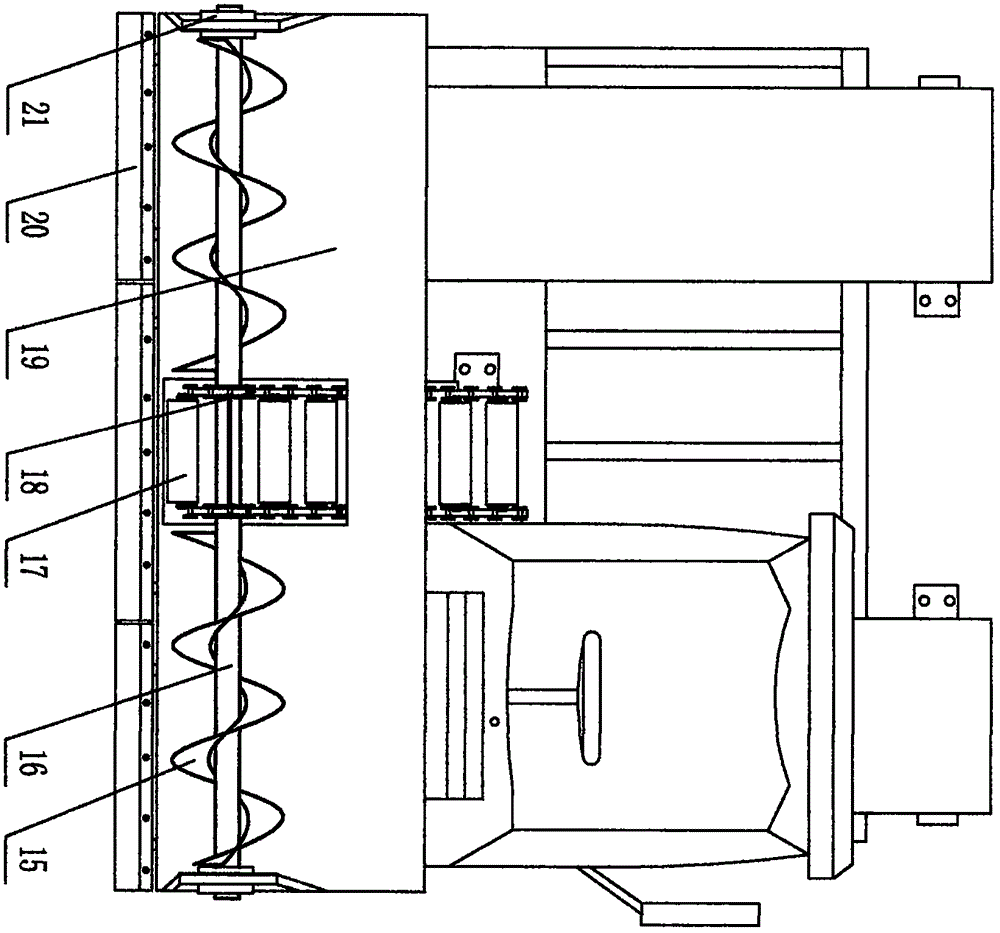

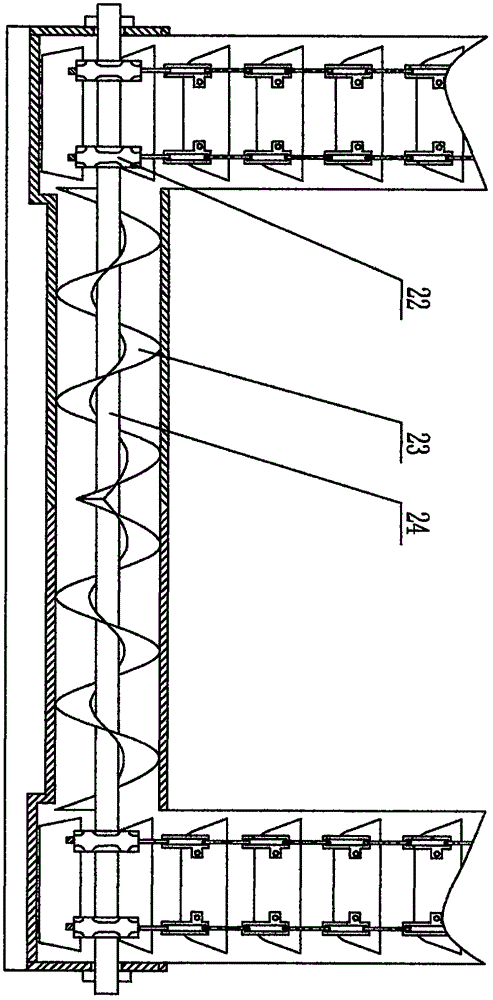

[0016] refer to figure 1 , figure 2 , the snow collection and snow removal shovel assembly (14) is installed on the front end of the special vehicle chassis (1), the composition of the snow collection and snow removal shovel assembly (14) is based on the general snow removal shovel, wherein the snow accumulation plate (19) and the transmission The lower end of the base plate (13) is fixedly connected, the upper end of the transmission base plate (13) is connected with the special vehicle chassis (1) through the fixed shaft (10), the motor drum (11) is installed on the upper end of the transmission base plate (13), and the transmission base plate (13) ) is connected with the deflector (9), the two ends of the transmission chain (18) are connected with the snow auger shaft (16) and the motor drum (11) respectively, and several scrapers (17) are connected on the transmission chain (18) Up; the snow auger sheet (15) rotates left and right and is installed on the snow auger shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com