High-efficiency snow sweeper and manufacturing method thereof

A manufacturing method and technology of snow removal vehicles, which are applied to snow surface cleaning, cleaning methods, construction, etc., can solve the problems of low operation efficiency, increased snow removal operation cost, and inability to complete snow removal operations independently, so as to achieve simple structure and improve snow removal operation efficiency , The effect of reducing the cost of snow removal operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

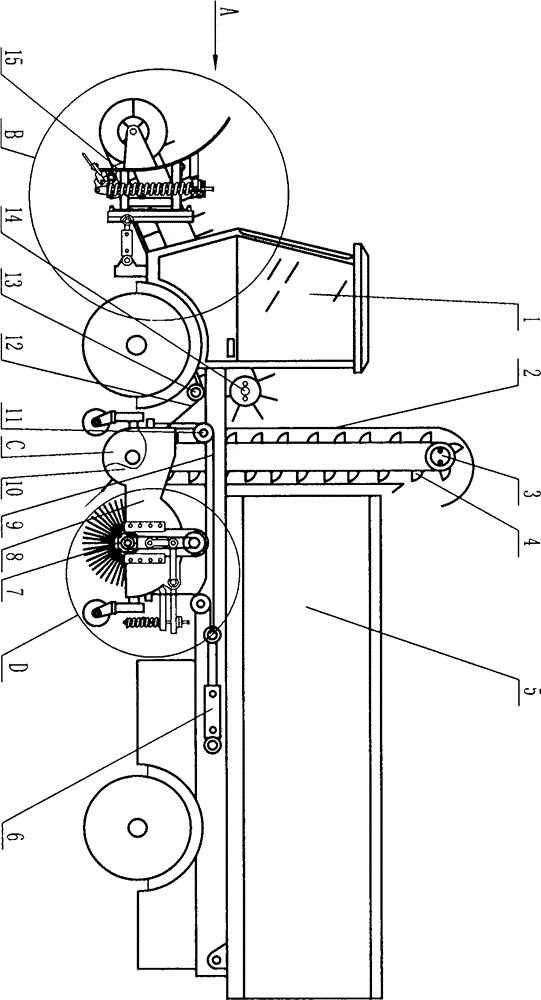

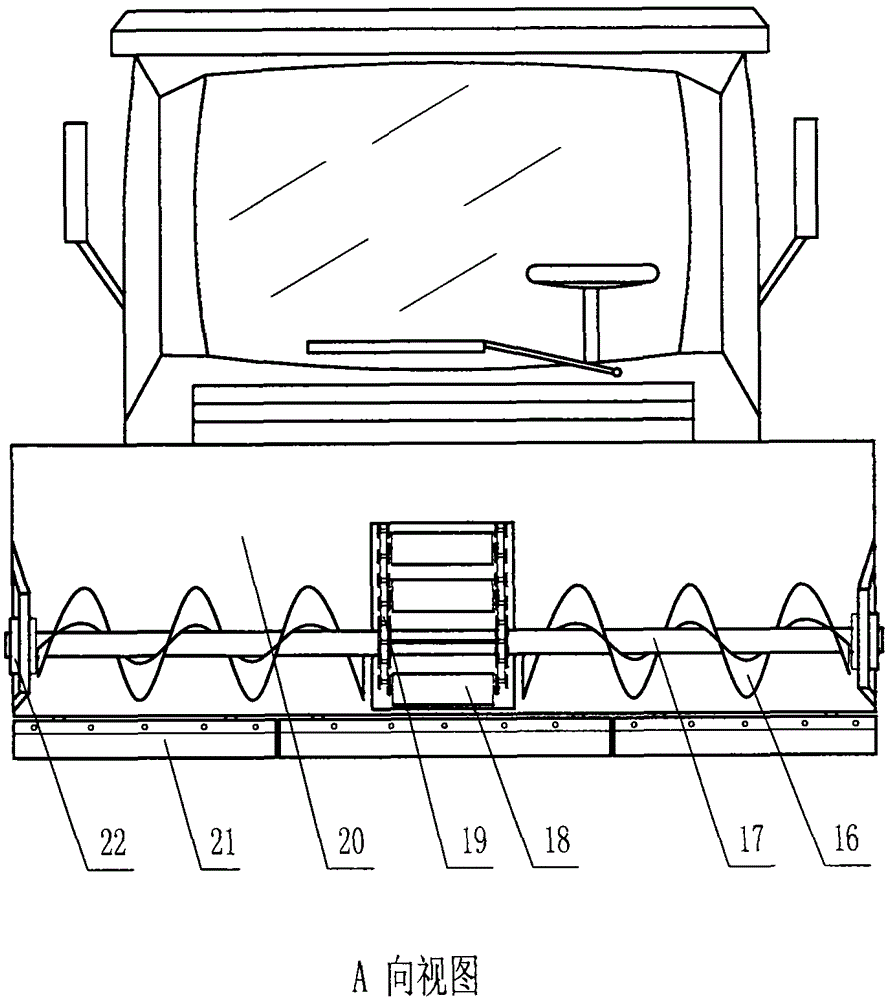

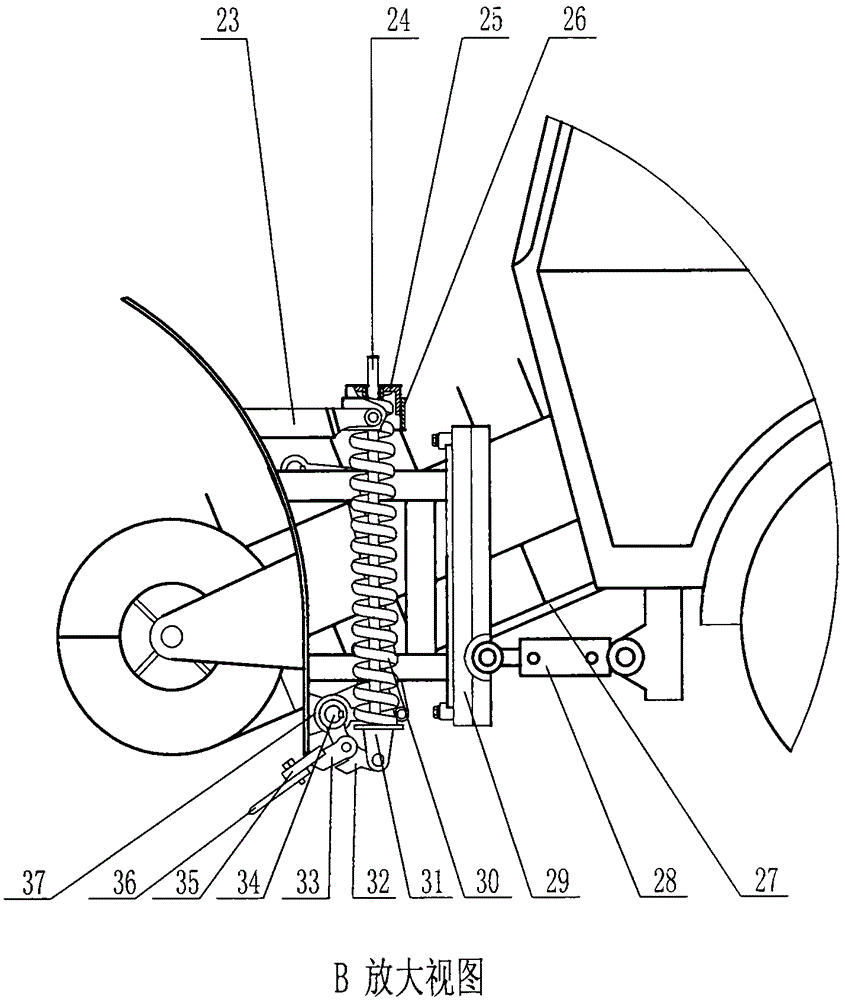

[0019] first figure 1 Special-purpose chassis car (1) is the low plate of special-purpose car, and snow collection and snow removal shovel assembly (15) are installed on the front end of special-purpose chassis car (1), and snow collection and snow removal shovel assembly (15) the inside image 3 The upper end of transmission bottom plate (27) passes through figure 1 Fixed axle (13) is connected with special-purpose chassis car (1), and lower end and figure 2 Snow plate (20) is pressed repeatedly, and motor drum (14) is installed on image 3 The upper end of the transmission bottom plate (27), the transmission bottom plate (27) is connected with the deflector (12), figure 2 The two ends of transmission chain (19) are respectively connected with snow-collecting auger shaft (17) and motor drum (14), and several scrapers (18) are connected on the transmission chain (19). The snow-collecting auger sheet (16) rotates left and right and is installed on the snow-collecting auger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com