A hanger feeding tool with linked hands

A technology for feeding tools and hangers, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of no emergency loss, inaccurate calculation of tensile force, affecting production operations, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

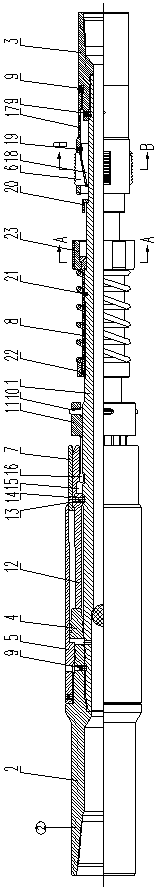

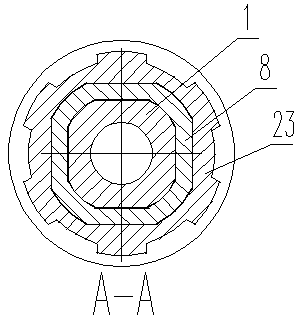

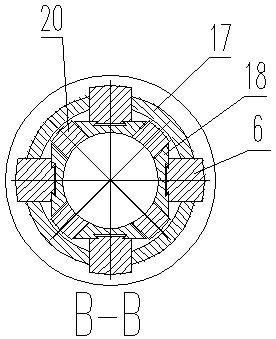

[0026] The interlocking hanger feeding tool includes a center pipe 1, an upper joint 2, a lower joint 3, a piston 4, a cylinder liner 5, slips 6, a setting sleeve 7 and a spring sleeve 8. One end of the central pipe 1 is threaded with an upper joint 2, and the other end of the central pipe 1 is threaded with a lower joint 3; the center pipe 1, the upper joint 2 and the lower joint 3 are respectively fixed by hexagon socket set screws 9. A cam block 10 is installed on the central tube 1 on one side of the upper joint 2, and an elastic pawl 11 is installed on the cam block 10. Mounting holes are arranged radially on the elastic claw 11 , and the elastic claw 11 is mounted on the cam block 10 through the mounting hole.

[0027] The central pipe 1 between the elastic claw 11 and the upper joint 2 is installed with a piston 4 through the cylinder liner 5, and the cylinder liner 5 and the upper joint 2 are threadedly connected, and the cylinder liner 5 and the upper joint 2 are tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com