Flat dies for calendered film extrusion

A calendered film and flat-mouth technology, which is applied in the field of calendered film extrusion, can solve the problems of large differences in transverse tensile strength, large friction, and low surface quality of film blanks, and achieve high uniformity of film blank thickness and wide web width. Good uniformity and consistent tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

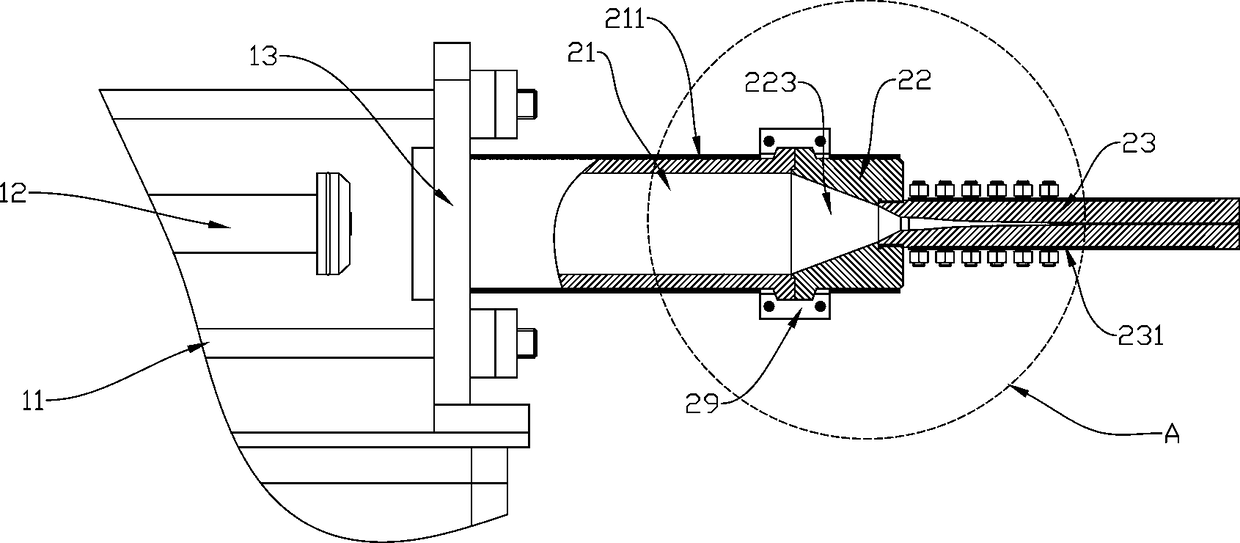

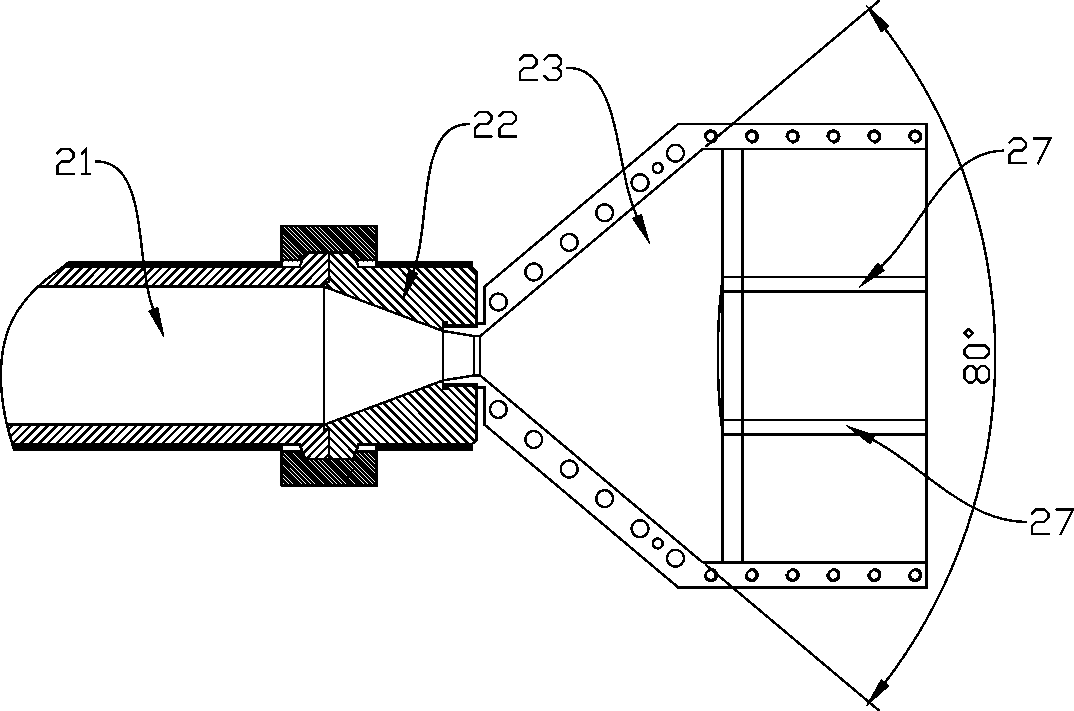

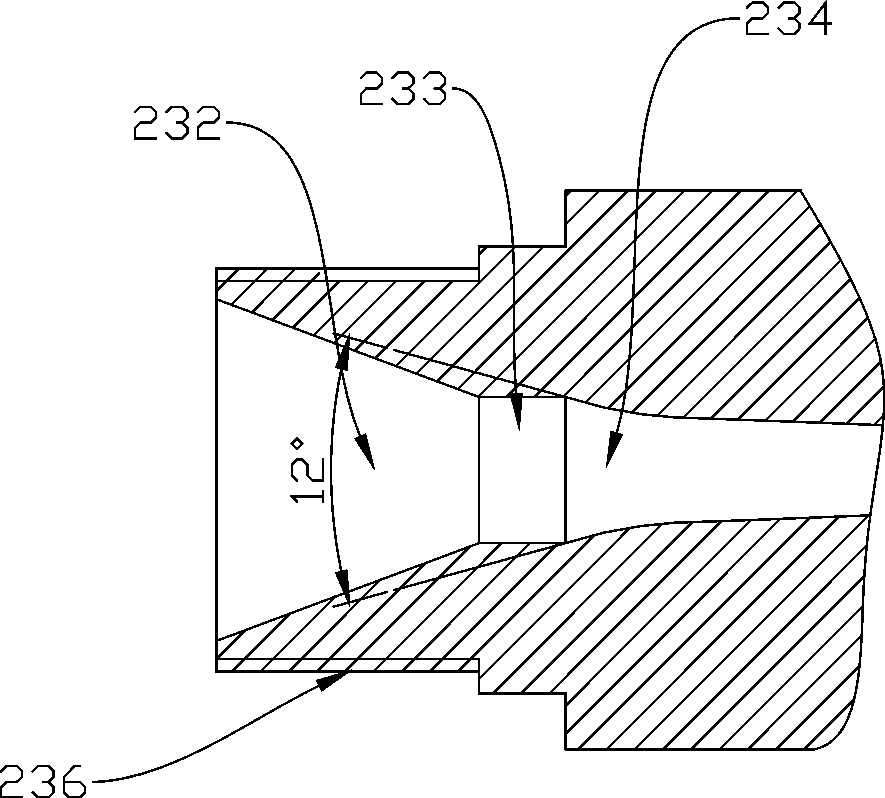

[0024] See Figure 1 to Figure 5 , a flat die for extrusion of calendered film, including an extrusion cylinder 21 connected to the pusher 11 (the inner surface roughness of the extrusion cylinder 21 is Ra0.4), the outlet of the extrusion cylinder 21 The end of the transition joint 22 (the roughness of the inner cavity surface of the transition joint 22 is Ra0.8) is connected to the inlet end, and the outlet end of the transition joint 22 is connected to the inlet end of the flat forming mold 23. The forming die 23 (the roughness of the inner cavity surface of the forming die 232 is Ra0.4) is composed of two half-mold bodies, the two half-mold bodies are positioned with cylindrical pins and fastened by M12 and M16 high-strength bolts; the transition The joint 22 has a first inner cavity 223 that gradually narrows from its inlet end to the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com