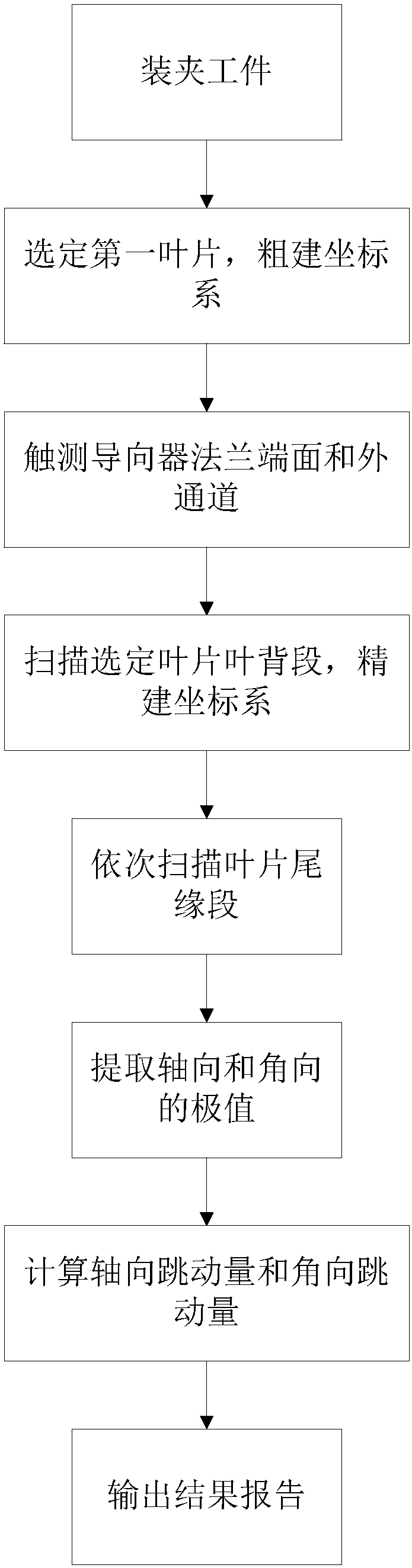

A rapid measurement method for the runout of the trailing edge of the guide vane based on three coordinates

A technology of three-coordinate measurement and measurement method, which is applied to measurement devices, instruments, etc., can solve the problems affecting the deployment of turbine guides, the progress of assembly and commissioning, the performance of the whole engine, the difficulty of aligning the end face of the central axis, and the human error of aligning and leveling. To achieve the effect of reducing labor intensity of workers, stable measurement and calculation, and reducing measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

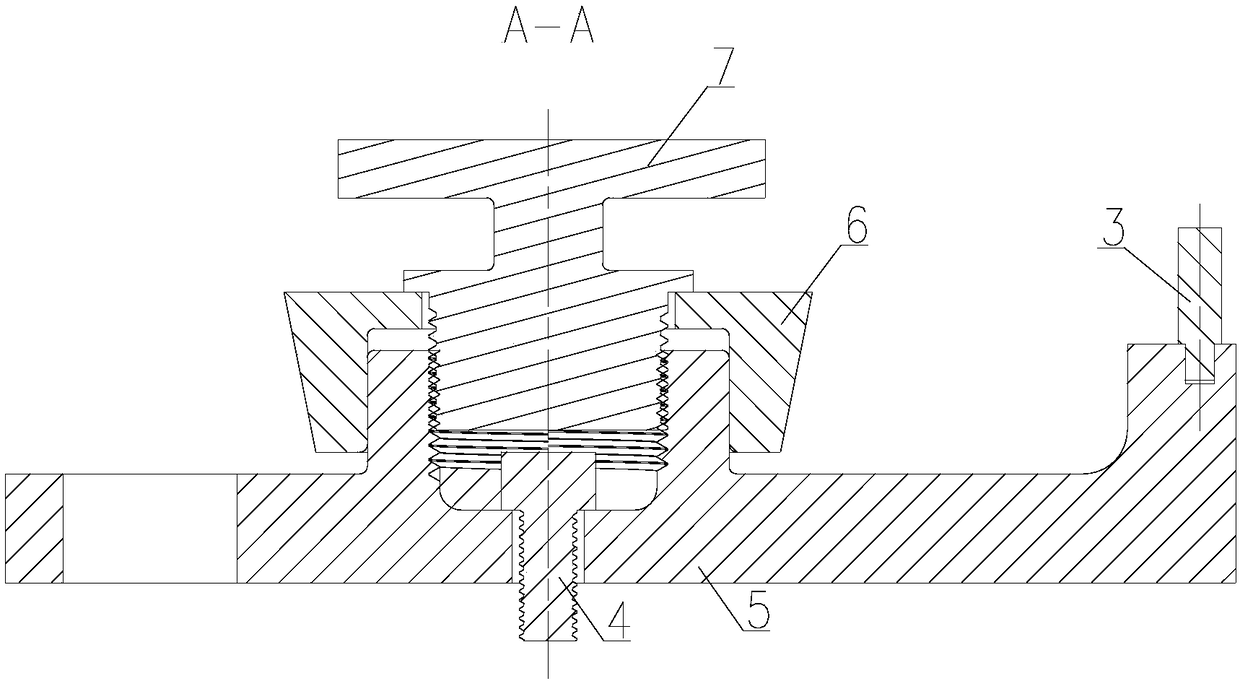

[0042] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention.

[0043] The method of the present invention is used to measure the runout of the trailing edge of a guider containing 19 blades.

[0044] Step 1, clamp the workpiece, select three blades among the blades of the guide: the first blade, the eighth blade, and the fourteenth blade; the angle between the selected three blades is less than or equal to 180° and greater than 60° ;Place the leading edge of the selected blade on the platform 1, rotate the guide to make the selected blade tangent to the positioning pin 3; set the inclined cone 6 on the base 5, and tighten the locking bolt 7, and ensure that the locking is tightened When the bolt is 7, the blade sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com