Data transmission device for flue-cured tobacco control information

A technology of data transmission device and control information, which is applied in the direction of measuring device, program control, computer control, etc., and can solve the problems of consuming time and energy of flue-cured tobacco masters, unfavorable adjustment of production progress, timely processing of errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

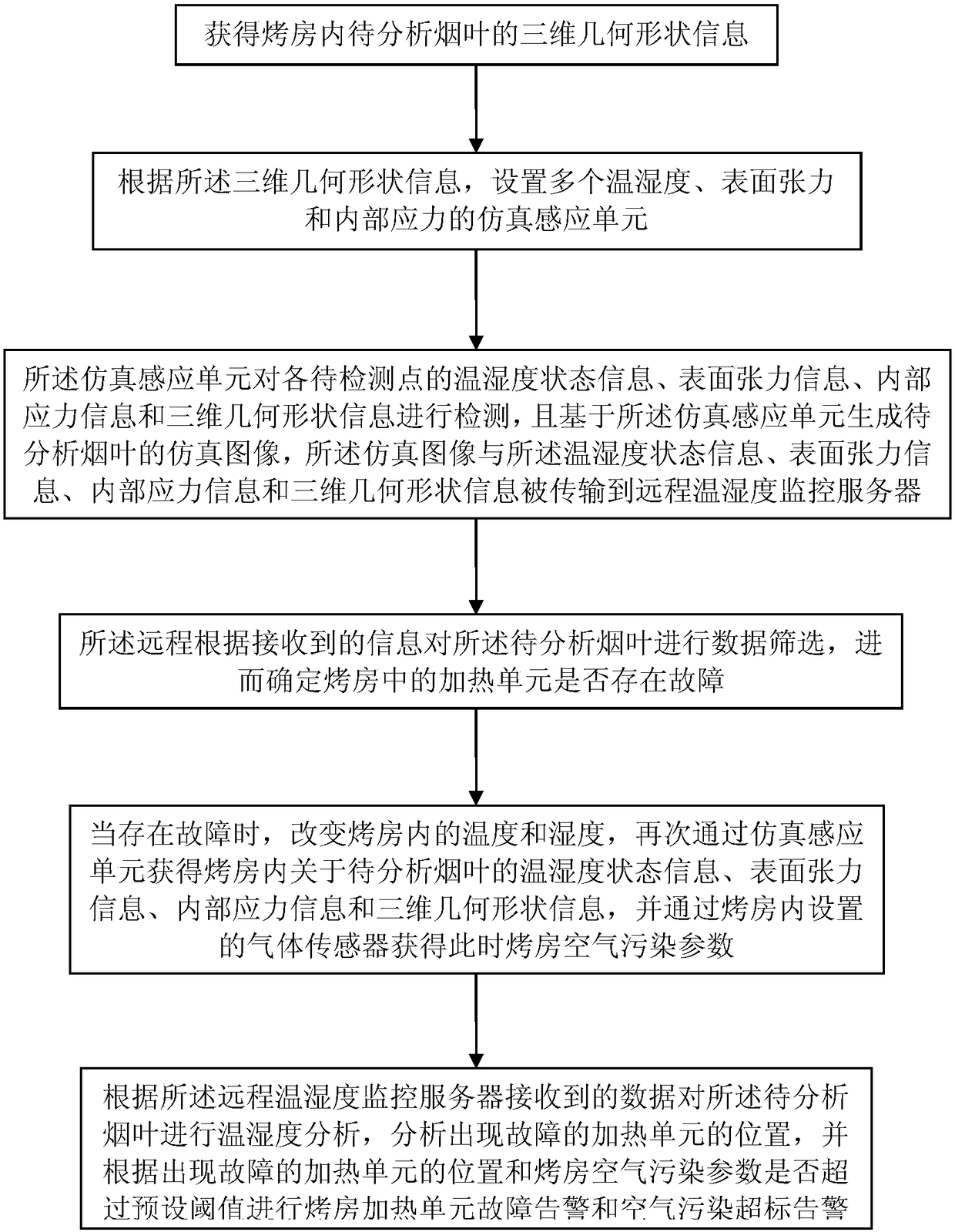

[0059] Such as figure 1 As shown, according to a preferred embodiment of one aspect of the present invention, a method for monitoring the environment of a flue-cured tobacco workshop is provided, including:

[0060] (1) Obtain the three-dimensional geometric shape information of the tobacco leaves to be analyzed in the flue-cured room;

[0061] (2) According to the three-dimensional geometric shape information, a plurality of simulation sensing units of temperature and humidity, surface tension and internal stress are set;

[0062] (3) The simulation sensing unit detects the temperature and humidity state information, surface tension information, internal stress information and three-dimensional geometric shape information of each point to be detected, and generates a simulation image of the tobacco leaf to be analyzed based on the simulation sensing unit. The simulation image and the temperature and humidity state information, surface tension information, internal stress inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com